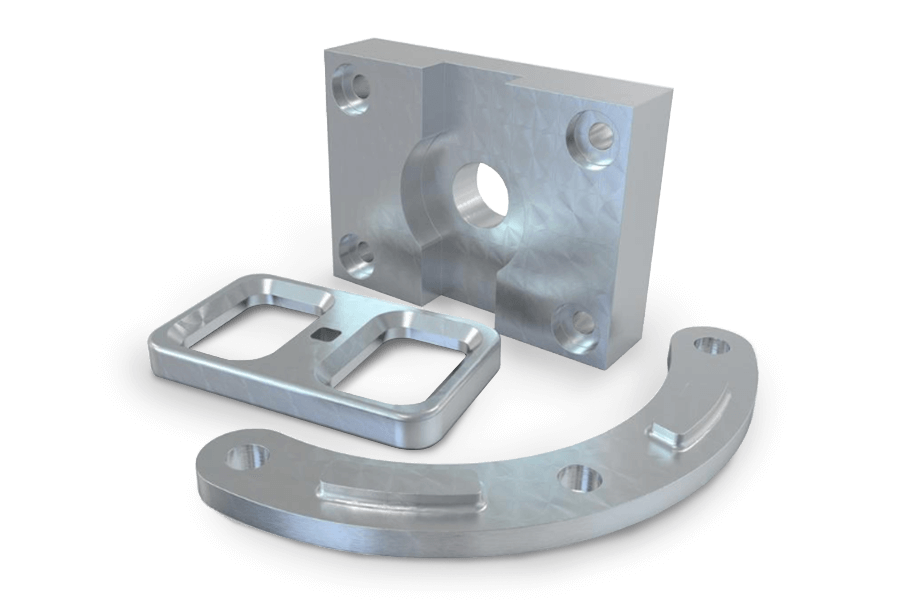

Metal Material

Metal Material Overview

Metal materials, known for their strength and durability, play a crucial role in various industries. Their mechanical properties, corrosion resistance, and thermal conductivity vary across metals, emphasizing the importance of tailored selection. Whether it’s the high strength of steel, the lightweight nature of aluminum, or the corrosion resistance of stainless steel, each metal brings distinct advantages.

In choosing the suitable metal for your project, meticulous attention to these characteristics ensures optimal performance. Understanding your application’s specific demands allows for precise material selection, promoting durability and functionality.

Following are some of the common metal types we offer

- Aluminum 6061

- Aluminum 7075

- Stainless Steel 304

- Stainless Steel 316

- Carbon Steel 1045

- Brass

Material Modification

Contract Manufacturing Metal Solution

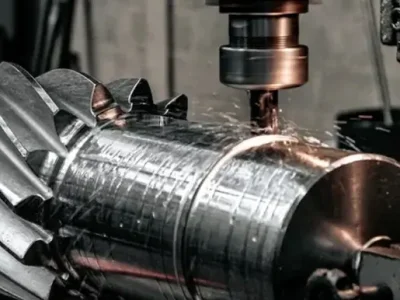

CNC Turning

Design for Manufacturability

Assembly Manufacturing

Advantages of Metal Material in Manufacturing

Exceptional Strength

Durability and Longevity

Versatility in Applications

Thermal Conductivity

Metal Parts in Different Industries

Popular Post

The Essential Guide to Effective Venting in Injection Molding

Venting in injection molding is an important aspect of the injection molding process that ensures high quality plastic parts and

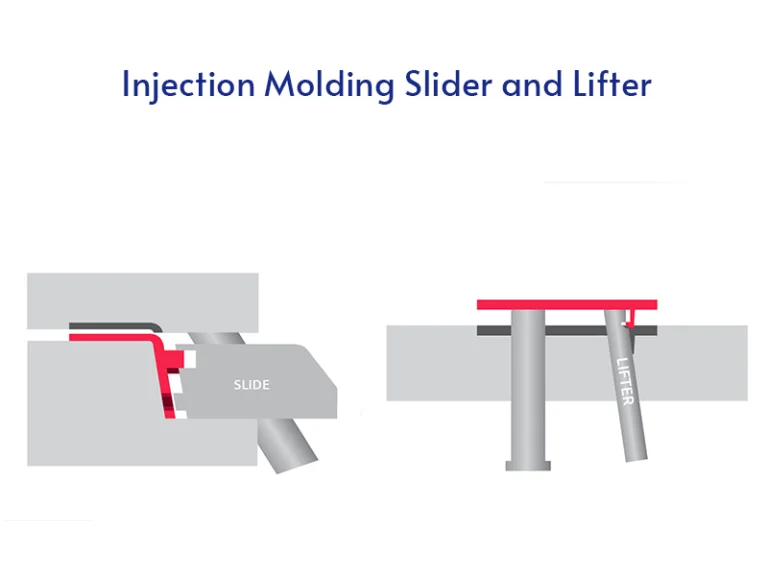

Understanding Injection Mold Slider and Lifter

Injection mold slider and lifter are crucial components in injection mold design Sliders and lifters in injection molding expand the

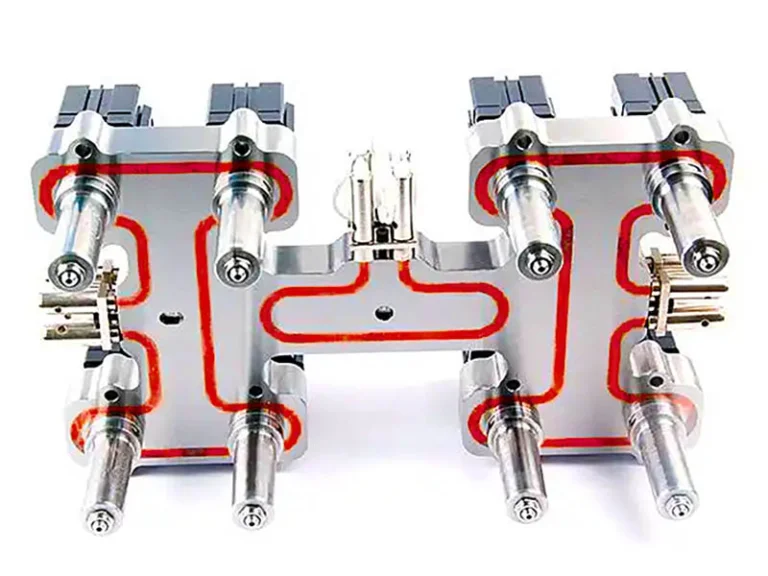

Hot Runner in Injection Molding – A Detailed Guide to Hot Runner System

Hot runner in injection molding helps accurately manufacture plastic components that cater to numerous industries If you want to know