Assembly Manufacturing

Contract Assembly Service - Secondary Operation Saves Your Time and Cost

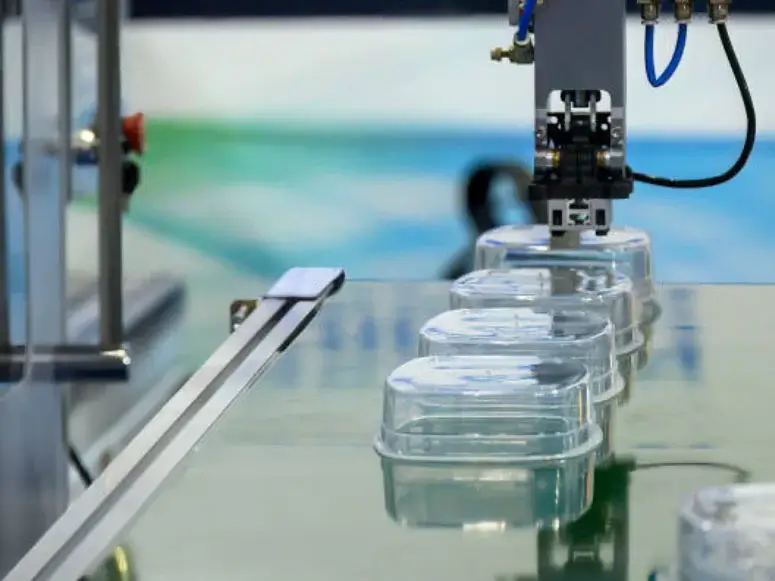

- Customized assembly services: Depending on quantity and requirements, we carry out manual, semi-automatic, or fully automated assembly operations.

- Available technologies: welding, bonding, soldering, screwing, riveting, and many other connections.

- Gasket and Sealant Application/Leak Testing (Air and Water)

- Electronic Installation and Testing

- Custom Packaging and Sourcing

Jiangzhi Product Assembly Manufacturing

At Jiangzhi, we offer innovative contract manufacturing in China, directly from our facilities in house(plastic, rubber and metal), and do final product assembly and packing. Regard as your partner factory next to you, we assume overall responsibility for in-house manufacturing and assembly, coordinating all interfaces.

We manage the entire process, from planning to functional testing. This includes procurement of purchased parts, manufacturing, assembly, and custom packaging. Support in product development, design, and optimization if needed. Our integrated capabilities not only increase efficiency but also ensure a higher level of quality assurance, as well as lower budget costs.

Jiangzhi Contract Manufacturing Process

Assembly and Joining Technologies

- Ultrasonic Welding

- Thermal Processing

- Thermal Imbedding

- Gluing

- Plug connections

- Clamp connections

- Threaded connections

- Rivet connections

- Bolt connections

- Form-Fit connections

Assembly Your Products with Jiangzhi Contract Manufacturing

Increased Flexibility

Leveraging Expertise

Focus on Core Competencies

IP Protection

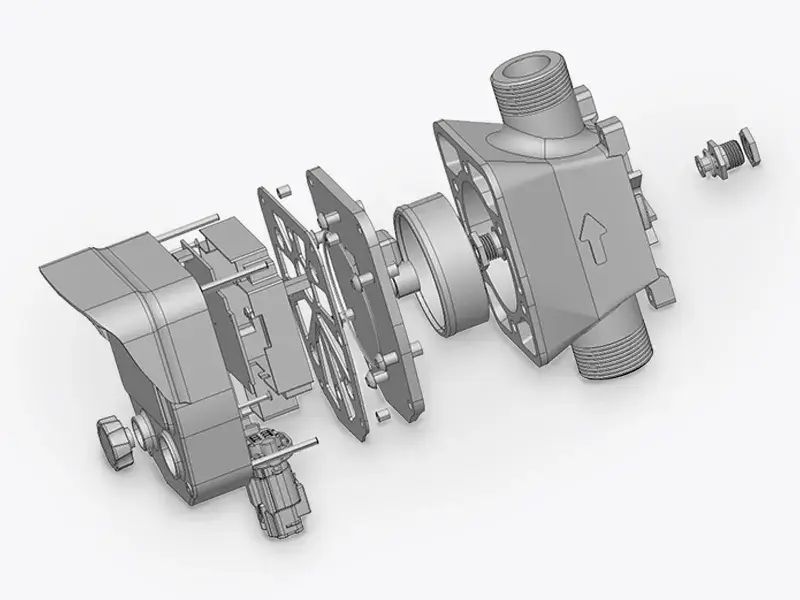

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing

Popular Post

The Essential Guide to Effective Venting in Injection Molding

Venting in injection molding is an important aspect of the injection molding process that ensures high quality plastic parts and

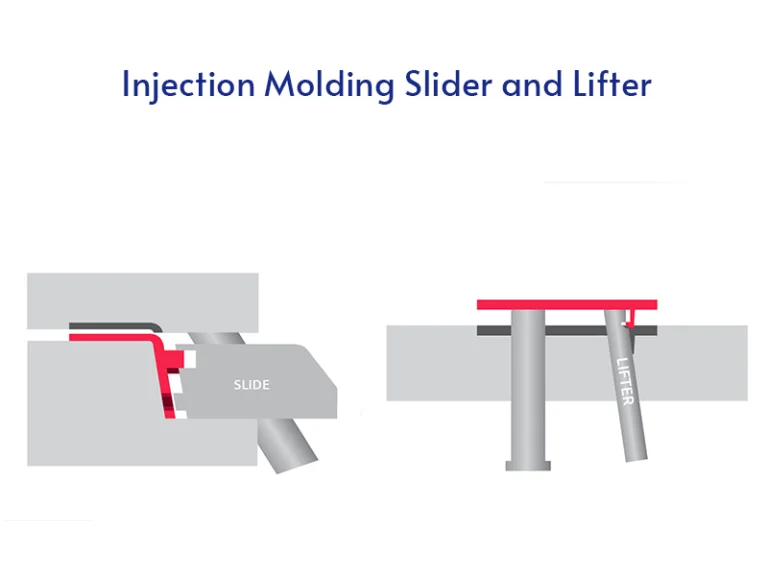

Understanding Injection Mold Slider and Lifter

Injection mold slider and lifter are crucial components in injection mold design Sliders and lifters in injection molding expand the

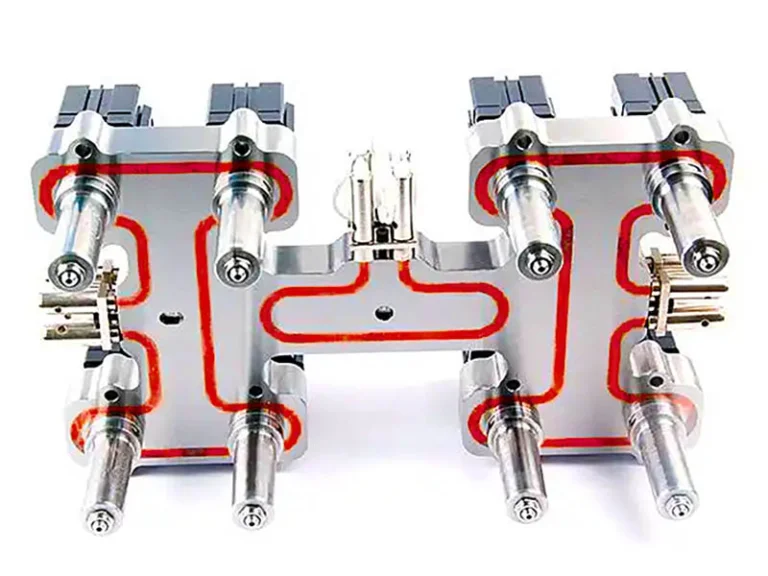

Hot Runner in Injection Molding – A Detailed Guide to Hot Runner System

Hot runner in injection molding helps accurately manufacture plastic components that cater to numerous industries If you want to know