Large Part Injection Molding

Get high-quality plastic parts in large size. Upload drawing and get quotation!

We operate injection molding presses up to 1,000 ton to support large part applications, which can process plastic parts maximum to 2000*1500mm. Following is a lit of what you can expect from utilizing injection molding for production of your parts.

- In-house mold production to improve efficient and save cost

- Can process a wide range of plastic materials

- Robotics and in-house manufacturerd end-of-arm tooling ensure effcient cycle times

- Additional capabilities inclding bonding, painting, printing, assembly and custom packaging

Large Part Injection Molding Mold Service

| Name | Detail |

|---|---|

| Maximun Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever (Only damage the mold after your permission) |

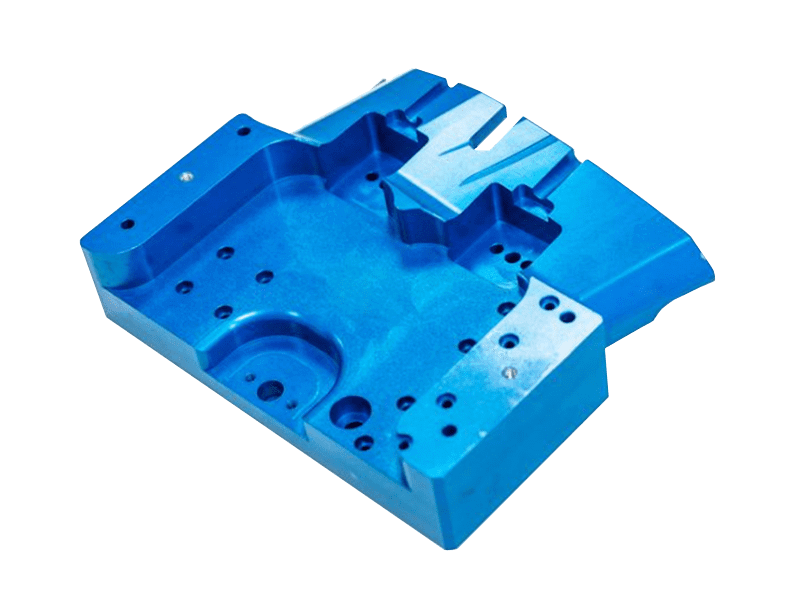

| Mold Material | Tool steel, stainless steel, aluminum |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

| Mold Lead Time | Generally 30~40 days for large part injection molding |

Injection Molding Surface Finishing

From smooth and glossy to textured and matte finishes, we offer a range of surface treatments to meet your design preferences. We primarily offer SPI finishing, VDI is also available is needed.

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

Injection Molding Material Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for injection molding is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Optimizing Large Part Injection Molding

Mold & Tooling Service

In-house mold fabrication service, from tooling desing to production. Life time mold guranteed.

Design for Manufacturability

Quality manufacturing starts with good design. We develop DFM reports to eliminate defects before production begins.

Surface Finishing

From smooth, glossy coating to textured or matte finishes, enhance the appearance and functionality by variours surface finishing.

Assembly Manufacturing

We provide customized assembly services depends on quantity and requirements, we carry out manual, semi-automatic, or fully automated assembly operations.

FAQs of Large Size Injection Molding

What is considered "large size" injection molding?

Large size injection molding typically refers to parts with surface areas of 100 square inches or more. It generally requires injection molding machines with clamping forces of 500 tons or higher.

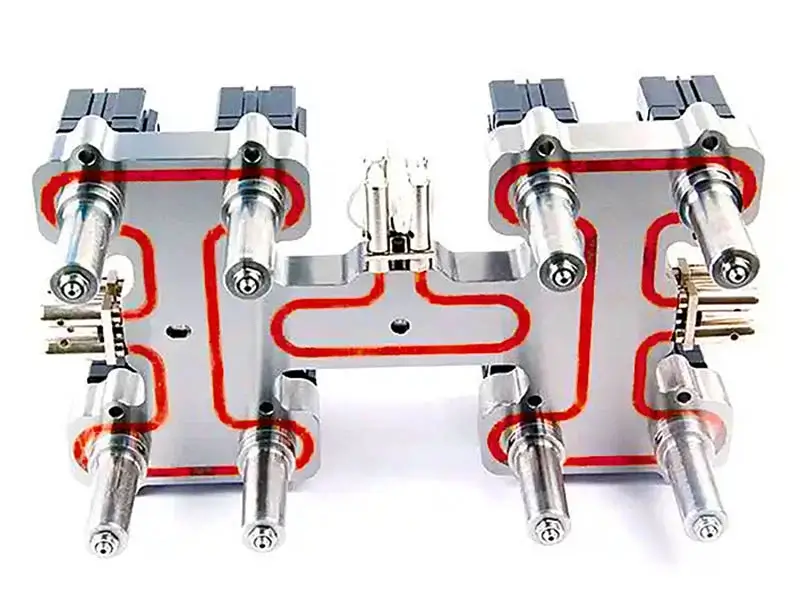

What are some key considerations for large size mold design?

Important factors include:

- Proper gating and runner system design

- Optimized cooling channels

- Structural reinforcement to prevent warpage

- Ejection system capable of handling large, heavy parts

- Venting to allow air to escape from large cavities

How do you determin the machine size needed for a large part?

A general rule of thumb is to use 2-8 tons of clamping force per square inch of part surface area. Other factors like wall thickness, part geometry, material viscosity, and mold temperature also influence the required clamping force.

What are the typical materials used in large-part injection molding?

Large-part injection molding often requires materials that can maintain their properties and structural integrity over larger surface areas and volumes. The typical plastic materials include:

- Polypropylene (PP)

- Polystyrene (PS)

- High-Density Polyethylene (HDPE)

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon (Polyamide – PA)

- Acetal (Polyoxymethylene – POM)

- Polycarbonate (PC)

- Acrylic