Custom Compression Molding Services

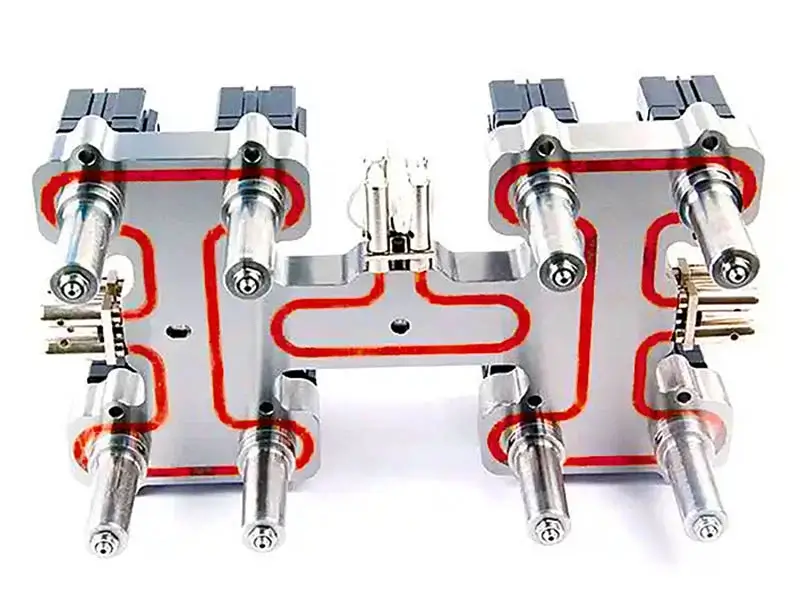

Compression Molding Capabilities

| Name | Detail |

|---|---|

| Size |

98.42in. x 78.74in. x 39.37in. 2500mm x 2000mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

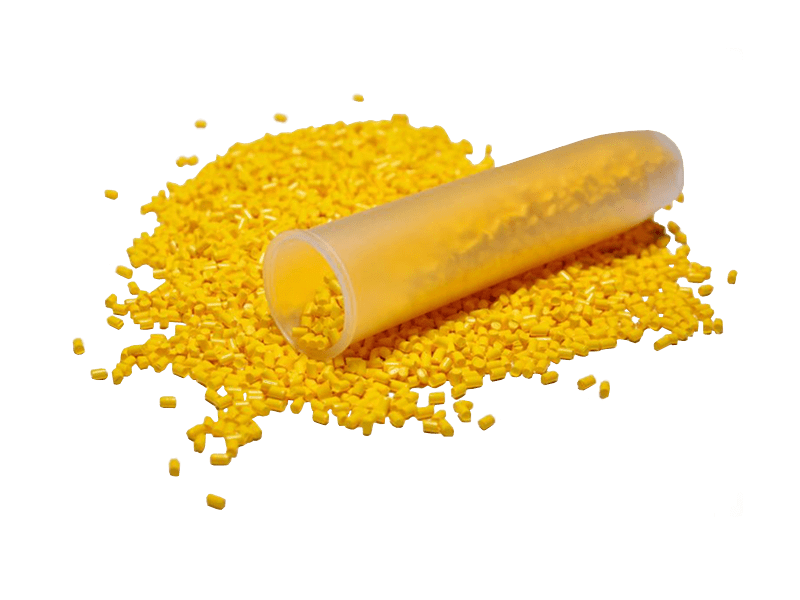

Compression Molding Materials

Rubber Materials

- Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- Nitrile (NBR)

- Neoprene (CR)

- SBR (Styrene Butadiene Rubber)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

Plastic Materials

- Nylon

- PP

- HDPE

- UHMWPE

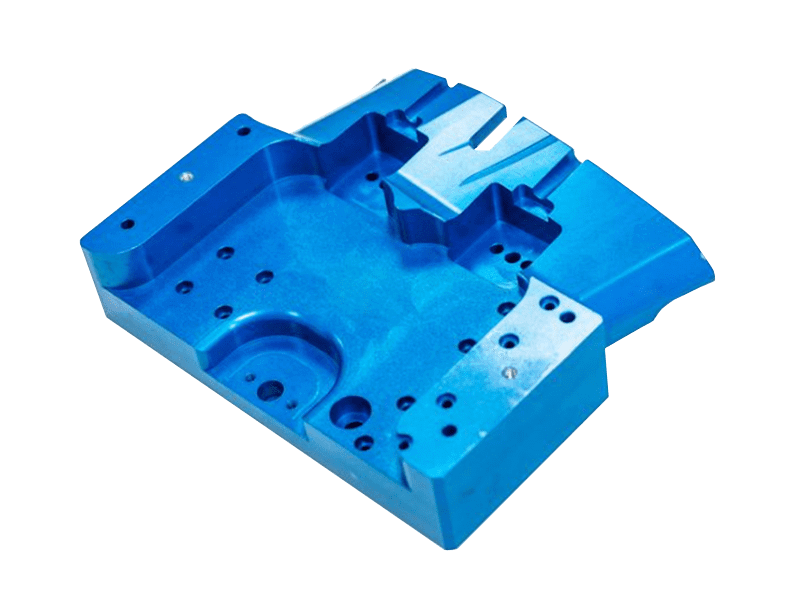

Compression Molding Surface Finishing

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

The Essential Guide to Effective Venting in Injection Molding

How Does Compression Molding Work

Material Loading

Mold Closure and Heating

Compression and Curing

Cooling

Cycling

Advantages of Compression Molding

From intricate designs to high-volume production, compression olding stands out with its precision, efficiency, and adaptability.

- Cost-effective for large production runs due to its high prodcution output and reduced material waste.

- Ensures consistent part quality and minimal variation between parts in large batches.

- Well-suited for high-volume prodcution, contributing to faster lead times and efficient manufacturing processes.

- Minimized material waste, contributing to a more sustainable and environmentally friendly manufacturing process.

Compression Molding Application

Compression molding produce a wide range of rubber and plastic molding parts across varios industries. Here are some common parts.

- Rubber seals and gaskets

- Plastic insulators for electrical components

- Rubber industrial bushings

- Consumer goods handles

- Plastic enclosures for electronic devices

- Oil seal

Why Choose Us

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Contract Manufacturing Solution

Mold & Tooling Service

Design for Manufacturability

Surface Finishing

Assembly Manufacturing

FAQs of Compression Molding

What are the factores affecting compression molding?

Important factors to be considered before the compression molding process are the following:

- Amount of plastic material

- Heating time

- Melting temperature of plastic material

- The pressure required to squeeze the material into the mold cavity

- Cooling time

Is compression molding good for environment?

Compression moulding can help reduce the environmental impact of plastic production and disposal by minimizing waste and energy consumption and using recycle materials.

What is the cycle time of compression molding?

Compression molding require slower cycle time than injection molding, the time needed to start and repeat the sequence of operations is between 1-6 mins for compression molding.

Is compression molding cheaper than injection molding?

Injection molding is better suited to high-volume production, whereas compression molding is better suited to pliable and flexible materials. Generally, the upfront costs for compression molding are cheaper.