Rubber Products Molded Stages

How are rubber products molded? Here is the clearest detailed explanation of the rubber molding process. Including text and pictures. Step by step.

Stage 1:

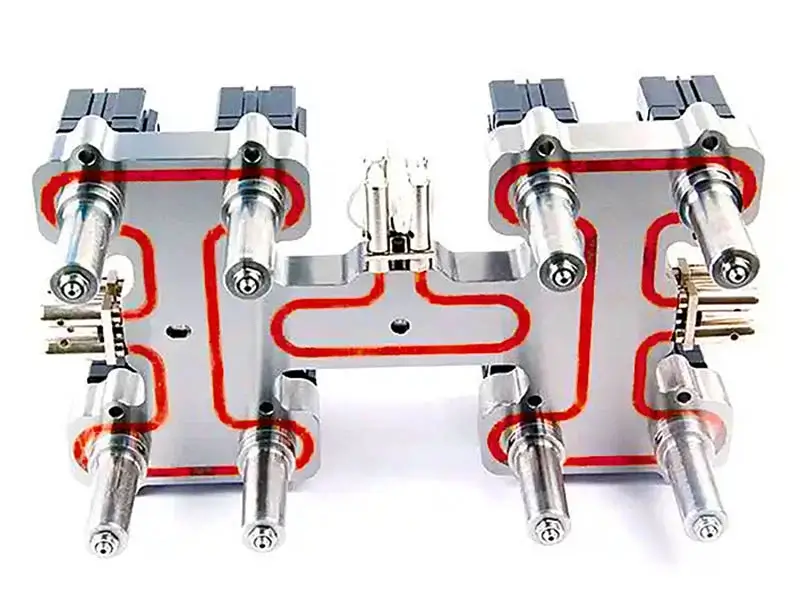

Heat and warm up the mold to a certain temperature.

Stage 2:

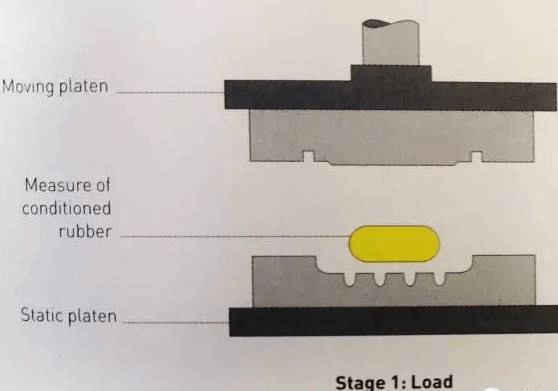

Open the mold and put a small piece of conditioned rubber into the cavity.

Stage 3:

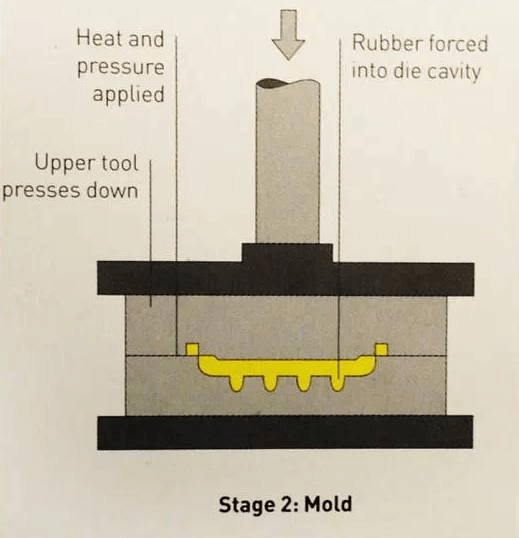

The upper and lower mold plates are combined, and the rubber pieces are vulcanized and formed under high temperature and pressure.

Stage 4:

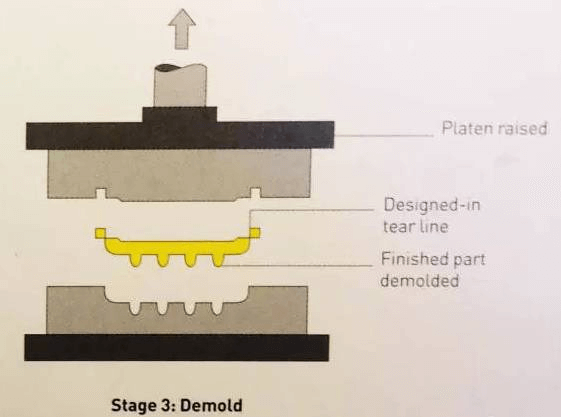

Demoulding, the molded rubber products are sent to the trimming workshop.

Example: Compression-Molded Rubber Button

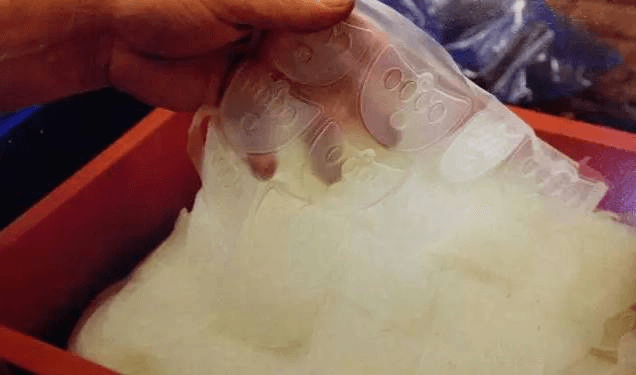

Step 1: Prepare quantitative small dice of rubber.

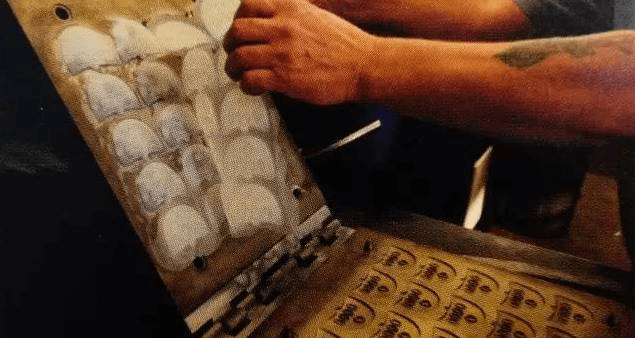

Step 2: Put the small dice of rubber into the cavities one by one.

Step 3: After heating the molds to 180°, combine the upper and lower mold plates. The rubber pieces are formed against the inner wall of the mold under high temperature and pressure and complete the molding process after 10 minutes.

Stage 4: Inject air into the cavities to de-mold the products.

Stage 5: Trimming and packing