High-Precision Custom Electronics Enclosures

Click to View

Injection Molding Solutions for Custom Electronics Enclosures

High-quality housings must meet strict requirements for structural strength, electrical insulation, thermal management, and precise fit, while supporting complex designs and aesthetic finishes.

At Jiangzhi, we specialize in precision injection molding of electronic enclosures, combining decades of experience, advanced tooling capabilities, and engineering expertise.

We maintain dimensional stability in thin-walled structures, achieve precise alignment for multi-part assemblies, and integrate inserts or overmolded seals without warping. Materials are selected based on mechanical strength, thermal behavior, and compatibility with electronic components to ensure performance and durability. By optimizing mold design, gating, and cooling systems, we help customers minimize deformation, reduce tooling iterations, and accelerate time to market for innovative electronic devices.

Electronics Enclosures Injection Molding Capabilities

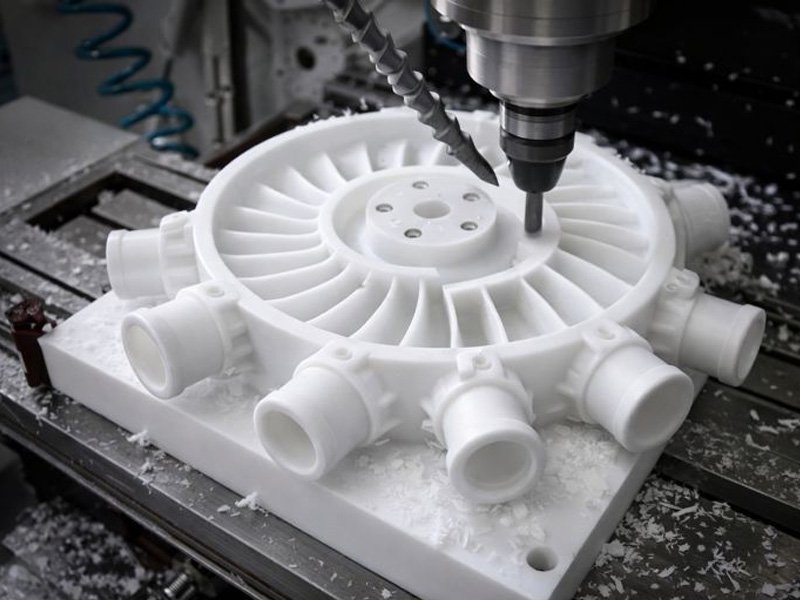

At Jiangzhi, we turn your enclosure parts designs into finished parts through precision injection molding. Using advanced injection molding machines ranging from 50T to 1200T, plastic is melted and injected into carefully prepared molds, cooled to solidify, and ejected as smooth, dimensionally accurate, and reliable enclosures. Every part undergoes strict inspection, and optional services like insert assembly, surface finishing, painting, and EMI/RFI shielding ensure your products are ready for mass production.

Comprehensive Testing and Quality Assurance

Get Your Custom Electronic Injection Molding Parts!

Common Electronic Enclosure Products

Jiangzhi specializes in producing high-precision plastic enclosures and functional parts for a wide range of electronic devices. With advanced injection molding technology and strict quality control, we deliver durable, accurate, and visually refined enclosure components. Typical products include:

- Plastic enclosures and control panels

- USB and PCB connectors

- Battery covers and charging bases

- Switch buttons and insulation parts

- Sensor enclosures and microcontroller casings

- LED enclosures, lamp holders, and light diffusers

- Earphone cases and mobile accessory shells

- Gaming console housings and structural components

FAQs About Injection Molded Electronic Enclosure Parts

Common options include PC, ABS, PC+ABS, aluminum, and transparent PC. The choice depends on strength, heat resistance, and appearance requirements.

Yes. We support tight tolerances through precision tooling, stable injection parameters, and dimensional inspection to ensure consistent fit with PCBs and internal components.

Yes. We can design sealing structures (gaskets, O-rings, snap-fits) to achieve IP54–IP67 levels depending on your requirements.

Yes. We produce custom electronics enclosures according to your design, including material selection, mold development, prototyping, and mass production.