CNC UHMWPE Machining Service

CNC Machining in UHMWPE Material

At Jiangzhi, we specialize in UHMWPE machining, offering precision CNC services for ultra-high molecular weight polyethylene (UHMW). Whether you’re working with prototypes or low-volume production, our team ensures tight tolerances, clean finishes, and consistent quality.

Machining UHMW polyethylene is a reliable solution for producing parts that demand extreme impact strength, abrasion resistance, and low-friction performance. Although UHMW is known for its toughness and ductility, which can make CNC milling and turning more challenging, UHMW plastic machining remains highly effective when done with proper tooling and expertise. Its durability and clean machinability make it a popular choice for wear pads, bushings, guides, and sliding components across various demanding industries. We handle tight tolerances, thick or thin wall sections, and custom requirements for your UHMW machined parts, helping you meet your performance and budget goals.

| Price | $$$ |

|---|---|

| Tolerances | ±0.015mm |

| Maximum Part Size | 900mm |

| Minimum Feature Size | Φ 0.7mm |

| Wall Thickness | 1.0mm |

| Lead Time | About 3-6 days |

CNC UHMW Machinability

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection | Heat Deflection Temperature | Melting Point |

|---|---|---|---|---|---|---|

| 20–30 MPa | 300–600% | R60–R70 | >150 J/m | 80–100°C | 60–80°C | 130–135°C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Looking for Ultra-Durable UHMW CNC Solutions?

Advantages & Disadvantages of CNC UHMWPE Machining

Advantages

- Exceptional abrasion resistance – long wear life in demanding environments

- Low friction surface – excellent for sliding and guide components

- Good chemical resistance – handles harsh cleaning agents and solvents

- Lightweight and durable – maintains strength without adding bulk

- Food-safe options – suitable for FDA-compliant applications

Disadvantages

- Difficult to machine – may deform or string without proper tooling

- Poor dimensional stability – higher thermal expansion than other plastics

- Surface finish limitations – rougher finish compared to harder plastics

- Not ideal for high-precision micro features

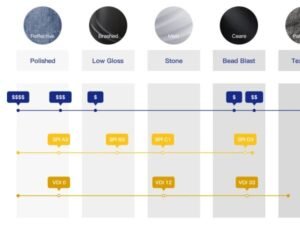

Surface Finishing for CNC Machining UHMW Parts

To improve the appearance, functionality, and wear resistance of your CNC machined UHMWPE components, we offer a range of surface finishing services. Whether you require a low-friction matte finish, improved cleanliness, or precise part marking, our finishing solutions are tailored to meet the unique properties and performance needs of UHMWPE machined parts.

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi CNC UHMW Machined Parts Are Guaranteed

FAQ About CNC UHMWPE Machining

Yes. UHMW plastic machining is ideal for making durable, low-friction parts. It’s perfect for tough environments like conveyors and marine use.

Both milling UHMW and turning UHMW require sharp tools and slower speeds due to its low stiffness and high slipperiness — but they produce excellent results when done right.

Machined UHMWPE offers great wear resistance, self-lubrication, and impact strength. It's a go-to for machining UHMW polyethylene in both industrial and food-grade applications.

Yes. We handle detailed UHMW designs and offer fast quotes after reviewing your CAD. Accurate pricing depends on design complexity and UHMW plastic machining requirements.

We guarantee satisfaction. If your parts don’t fit or perform, we’ll remake them—simple and hassle-free.