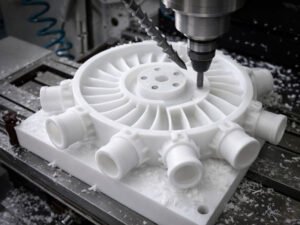

Aluminum CNC Machining Service

CNC Machining in Aluminum Material

At Jiangzhi, we specialize in aluminum CNC machining, offering reliable CNC services for both prototypes and small-batch production. With advanced multi-axis equipment and experienced machinists, we manufacture CNC aluminium parts with high precision, stable quality, and excellent surface finish—strictly based on customer-provided drawings or CAD files. Whether milling, turning, or drilling, we ensure your parts meet demanding tolerance and performance requirements.

Our aluminum CNC service supports a wide range of aluminum grades, including 6061, 7075, and 5052. These aluminium CNC parts are widely used across industries such as aerospace, electronics, automotive, and industrial equipment. From basic manufacturability review to precision Al machining, Jiangzhi ensures your cnc aluminium parts are delivered on time, on spec, and on budget.

| Price | $$$ |

|---|---|

| Tolerances | ±0.01mm |

| Maximum Part Size | 1200mm x 800mm x 300mm |

| Minimum Feature Size | Φ 0.5mm |

| Wall Thickness | 0.5mm |

| Lead Time | About 3-6 days |

Machining Aluminum Properties

Aluminium machining is favored for its excellent machinability, low density, and high dimensional stability. It supports high-speed CNC milling and turning with great surface finishes and minimal distortion, making it ideal for precision parts. Common aluminum grades used in CNC aluminum machining include:

- 6061 – the most widely used grade, offering good strength, corrosion resistance, and workability

- 7075 – a high-strength aerospace-grade aluminium, ideal for structural and load-bearing parts

- 5052 – known for excellent corrosion resistance and weldability, often used in marine and enclosures

- 2024 – strong and fatigue-resistant, used in aerospace and military components

- MIC 6 – cast aluminum plate with excellent flatness, ideal for tooling and fixtures

| Tensile Strength, Yield (MPa) | Hardness (HB) | Elongation at Break | Thermal Conductivity | Corrosion Resistance | Melting Point | CNC Machining Notes |

|---|---|---|---|---|---|---|

| 130–570 MPa | 35–100 | 8–18% | 150–235 W/m·K | Good to Excellent (alloy-dependent) | 615–660°C | Excellent machinability; use carbide tools |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Looking for High-Quality Al CNC Machining?

Advantages & Disadvantages of Aluminium CNC Service

Advantages

- Excellent machinability – clean, fast cuts with minimal tool wear

- Lightweight yet strong – ideal for structural or weight-sensitive parts

- Corrosion resistant – suitable for outdoor or humid environments

- Great thermal conductivity – perfect for heat sinks and electronic enclosures

- Attractive finish – smooth surface that’s easy to anodize or coat

Disadvantages

- Lower strength than steel – not suitable for all heavy-load applications

- Softness – can be prone to surface scratches without coating

- Tool marks – may require finishing for high-aesthetic parts

- Burrs – needs proper deburring for clean edge profiles

Surface Finishing Options for CNC Machined Parts

To improve the appearance and performance of your CNC machined aluminium components, we offer a variety of surface finishing services. Whether you need a clean matte surface, enhanced aesthetics, or clear part labeling, our finishing options ensure to meet your aluminum machining parts.

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi Aluminum Parts Machining Are Guaranteed

FAQs About Machined Aluminum Part

Aluminum is lightweight, easy to cut, corrosion-resistant, and offers a good balance of strength and cost—ideal for most industries.

Yes. Our aluminum cnc service regularly meets tolerances down to ±0.01 mm with excellent repeatability.

It depends. Many aluminium machined parts look great as-machined, but we also offer finishing like anodizing and polishing.

Absolutely. Send us your CAD file, and our engineers will optimize it for manufacturability and performance.