Silicone Compression Molding

What is Silicone Compression Molding?

Silicone compression molding is a traditional yet highly effective method for producing durable silicone parts. We use solid silicone rubber (not LSR) and press it into precision-machined molds under heat and pressure. This allows for excellent part integrity and reliable mechanical properties.

Our expertise in compression molding ensures tight tolerances, minimal material waste, and scalable production—from prototypes to high-volume batches. We offer high-quality products at low cost with reliable, on-time delivery. Partner with us for dependable quality, cost efficiency, and a supply chain you can count on.

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 1.5 mm – 8 mm |

| Maximum Part Size | 500mm × 500mm × 500mm |

| Minimum Feature Size | 0.8 mm – 1 mm |

| Tolerances | ±0.2mm – ±0.5mm |

Silicone Compression Molding Step-by-Step

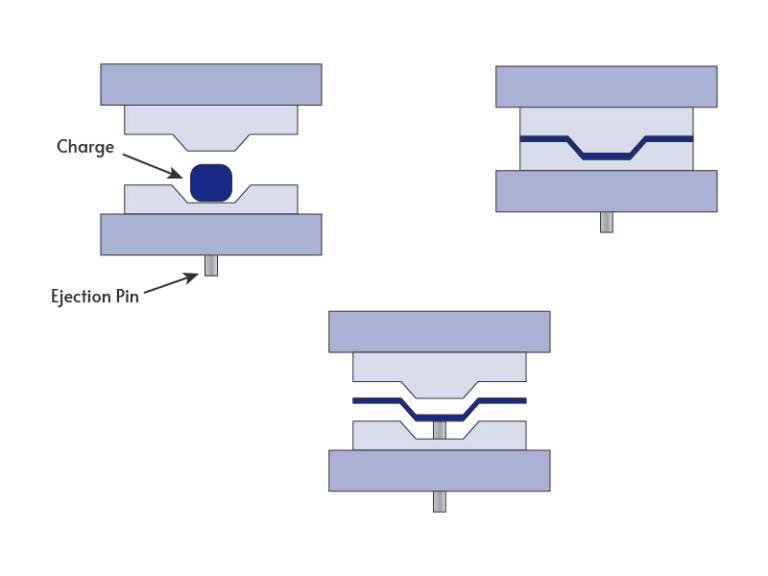

At our facility, we specialize in true compression molding for silicone parts — a process that combines simplicity, flexibility, and reliability. Unlike injection molding, compression molding uses pre-measured silicone blanks (often HCR) that are directly placed into the heated mold cavity.

- Material Preparation: High-consistency silicone rubber is cut and pre-formed to match the mold cavity size.

- Mold Loading: The material is carefully placed into the preheated mold cavity.

- Compression & Curing: The mold is closed, and pressure is applied Under heat and pressure, the silicone flows to fill the cavity and cures (vulcanizes) into its final shape.

- Demolding: After the set curing time, the mold is opened and the finished part is removed.

- Deflashing & Finishing: Any excess flash is trimmed, and additional post-curing can be applied if required.

This process is particularly well-suited for small-to-medium volume production, rapid design iterations, and parts requiring multiple silicone grades. With no gates or runners, parts are free from gate marks and tooling costs remain lower than injection molding.

Silicone Rubber Material Properties

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| Value/Description | 1.02–1.05 g/cm³ | 40 -50 MPa | 60-70 MPa | 20 -30 kJ/m² | 90-100℃ |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Looking for High-Quality Silicone Rubber Compression Molding?

Get Strong & Precise Compression Molding – Durable, Custom, and Cost-Effective! Request a Quote Today!

Advantages & Disadvantages of Silicone Compression Molding

Silicone Compression Molding Advantages

- Lower cost – Tooling is cheaper and can often be modified or reused.

- Faster turnaround – Shorter development cycles, enabling quick iterations and small-batch production.

- Simpler process – Requires less complex equipment, suitable for multiple silicone grades.

- Better appearance – No gates required, so parts are free of gate marks.

- High flexibility – Supports insert molding, fabric molding, and encapsulation.

- Wide material compatibility – Works with various silicone formulations without complicated material changes.

Silicone Compression Molding Disadvantages

- Not suitable for very large volumes – Less efficient than injection molding for mass production.

- Labor-intensive – Higher manual involvement increases part cost compared to injection molding.

- Flash formation – Parts often develop flash that must be trimmed; tooling design can reduce but not eliminate it.

- Longer demolding for complex parts – Mold plates must be removed before taking out the part, which can take significantly more time for intricate designs.

- Design limitations – Less suitable for very thin-walled or highly complex geometries compared to injection molding.

Applications of Compression Molded Silicone

Medical & Healthcare

- Silicone gaskets

- Mask components

- Sealing rings in diagnostic devices

Electronics & Electrical

- Silicone keypads

- Connector seals

- Heat-resistant insulators

Industrial Equipment

- Valve seals

- Shock-absorbing pads

- Dust-proof covers

Consumer Goods

- Baby products

- Kitchenware handles and grips

- Waterproof buttons

Jiangzhi Silicone Compression Molding Parts are Guaranteed

100% satisfaction: High-performance silicone rubber mouldings with excellent resilience, precise dimensions, and stable quality – your vision, expertly molded in silicone.