Custom Rubber Parts

Explore our capabilities and learn how we bring your custom rubber components to life, from material selection to final molding.

- A full range of rubber components

- Wide Range of Rubber Materials

- Custom Mold Design & Manufacturing

- ISO 9001:2015 quality certification

Rubber in natural or synthetic form is a flexible, durable alternative to metal and plastic for parts that need to flex, compress, and withstand repeated stress. It offers excellent elasticity, strength, and resistance to wear and aging, making it ideal for industrial, automotive, and sealing uses.

At Jiangzhi, we specialize in manufacturing precision custom rubber parts. With years of rubber molding experience, we offer contract customization and have built trusted partnerships in markets worldwide.

Our Molded Rubber Components Capabilities

Click to View

Rubber Compression Molding

Compression moulding is a cost-effective and widely used method for producing rubber parts. Pre-measured rubber material is placed directly into the mold cavity, then compressed and heated to cure and form the final shape. It is ideal for medium to high-volume production and for parts with simple to moderately complex geometries.

This process is particularly well-suited for producing simple, bulky, and medium-to-large sized rubber products with less intricate geometries. Products with thick walls and simple shapes are ideal because the process doesn’t rely on the rubber flowing through narrow channels, which can be a limiting factor in other methods.

Advantages:

- Tooling costs are generally lower and simpler to produce.

- This process can handle a wide variety of rubber compounds.

- The use of pre-measured blanks leads to very little material waste.

- It is an effective method for manufacturing large, thick-walled parts.

Disadvantages:

- The process is slower than other methods, leading to longer cycle times.

- It is more labor-intensive due to the manual loading and removal of parts.

- The method is not ideal for producing parts with complex geometries or tight tolerances.

- A secondary trimming operation may be needed to remove flash from the finished part.

Rubber Injection Molding

Rubber injection molding service is a precise and efficient method for producing custom rubber parts by injecting heated rubber into a mold cavity under high pressure. It is ideal for medium to high-volume production and parts with more complex geometries.

This process works well for producing small to medium-sized parts with intricate shapes and tight tolerances. The rubber is able to flow through thin channels, making it suitable for detailed designs.

Advantages:

- Excellent for complex and detailed geometries.

- High repeatability and consistent part quality.

- Reduced manual labor compared to compression molding.

- Faster cycle times for high-volume production.

Disadvantages:

- Tooling costs are higher and more complex.

- Not ideal for very large, bulky parts.

- Some rubber compounds with high viscosity may be difficult to process.

Rubber Extrusion

Rubber extrusion is a continuous process where rubber material is forced through a shaped die to create long, uniform profiles. It is commonly used for seals, hoses, tubing, and gaskets.

This method is best for producing continuous shapes with consistent cross-sections and moderate complexity. It is suitable for medium to high-volume runs where uniformity is critical.

Advantages:

- Efficient for producing long, continuous profiles.

- Consistent cross-sectional dimensions.

- Can process a wide variety of rubber compounds.

- Relatively low tooling costs for simple die shapes.

Disadvantages:

- Limited to parts with uniform cross-sections.

- Secondary operations may be needed for cutting or curing.

- Not suitable for highly intricate or three-dimensional parts.

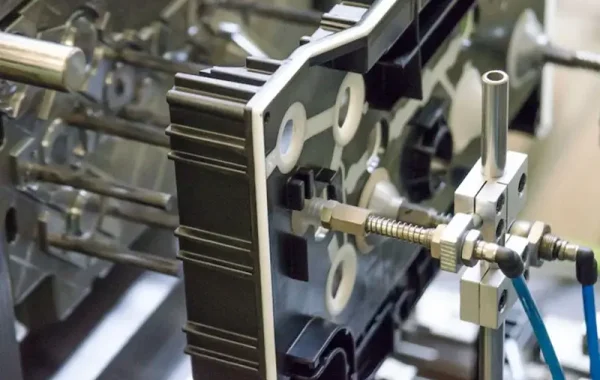

Rubber-to-Metal Bonding

Rubber-to-metal bonding combines rubber and metal into a single component, often using adhesion promoters and curing techniques.

It is widely used for vibration isolators, mounts, bushings, and other industrial rubber components. This process is ideal for applications requiring the mechanical strength of metal and the flexibility or damping properties of rubber.

Advantages:

- Produces durable, high-strength composite parts.

- Reduces assembly steps by bonding components directly.

- Enables customized mechanical and damping properties.

Disadvantages:

- Tooling and process can be more complex.

- Requires careful control of surface preparation and bonding conditions.

- Limited to compatible rubber and metal combinations.

Rubber-to-Plastic Bonding

Rubber-to-plastic bonding joins rubber and plastic materials into a single part, often for functional or sealing applications. It can be achieved through co-molding, adhesive bonding, or overmolding.

This method is well-suited for custom rubber parts that require a soft-touch surface, sealing properties, or integrated assembly of multiple materials.

Advantages:

- Combines the properties of rubber and plastic in a single part.

- Reduces the need for additional assembly.

- Suitable for ergonomic, sealing, and protective applications.

Disadvantages:

- Process requires precise control to ensure strong adhesion.

- Material compatibility is critical.

- Tooling and setup can be more complex than single-material molding.

Need Custom Molded Rubber Parts? Let’s Build Them Together.

Material Options for Molded Rubber Components

Selecting the right material for molded rubber components ensures optimal performance, durability, and cost-effectiveness, making it a critical step in any manufacturing process.

- Silicone

- EPDM

- NBR

- CR

- SBR

- NR

- IIR

- FKM

Custom Rubber Parts Application

Our custom molded rubber components are used across a wide range of industries. Common applications include:

- Grommets

- Rubber Plugs

- Rubber Caps

- Seals

- Gaskets

- Bushings

- Grips

- Vibration Mounts

- Non-slip Feet

- Molded Seals