Low Volume Injection Molding Services

Click to View

What Is Low-Volume Injection Molding?

Low-volume injection moulding refers to the production of a limited number of parts using injection molding services based on the customer’s specifications and requirements. By injecting high-quality plastic resin into metal molds, complex parts can be manufactured while ensuring outstanding precision, consistency, and reliability. Although injection molding is often used in mass production, small-batch injection molding can provide cost-effective solutions within a limited production scale and is highly suitable for prototyping, market testing, or customized projects.

Small Volume Injection Mold Service

Using high-quality steel molds, including single-cavity, multi-cavity, and family molds, we support everything from rapid prototyping to low-volume, on-demand production.

| Name | Detail |

|---|---|

| Mold Material | P20, H13, S136, NAK80 steel grades |

| Mold Types | Single-cavity, multi-cavity, family molds |

| Mold Life | 100 – 25,000+ shots (depending on material & complexity) |

| Quantity | 100 – 10,000+ parts |

| Surface Finish | SPI standard polishing, texturing, EDM, custom finishes |

| Lead Time | T1 samples in as fast as 2 weeks, depending on part complexity |

Low Volume Injection Molding Material Selection

Choosing the right material ensures consistent quality, functional performance, and cost-efficiency for your specific project.

- Thermoplastics: ABS, PC, PP, Nylon (PA), POM, PE, PMMA. These plastics are strong, easy to process, and chemically resistant, making them suitable for small-batch injection molded parts.

- Rubber Materials: EPDM, NBR, NR, CR, Silicone. These rubbers are flexible, wear- and oil-resistant, and ideal for seals and soft-touch components in low-volume production.

- TPE: TPV, TPU. These thermoplastic elastomers combine plastic processability with rubber elasticity, perfect for flexible or ergonomic parts in small-batch runs.

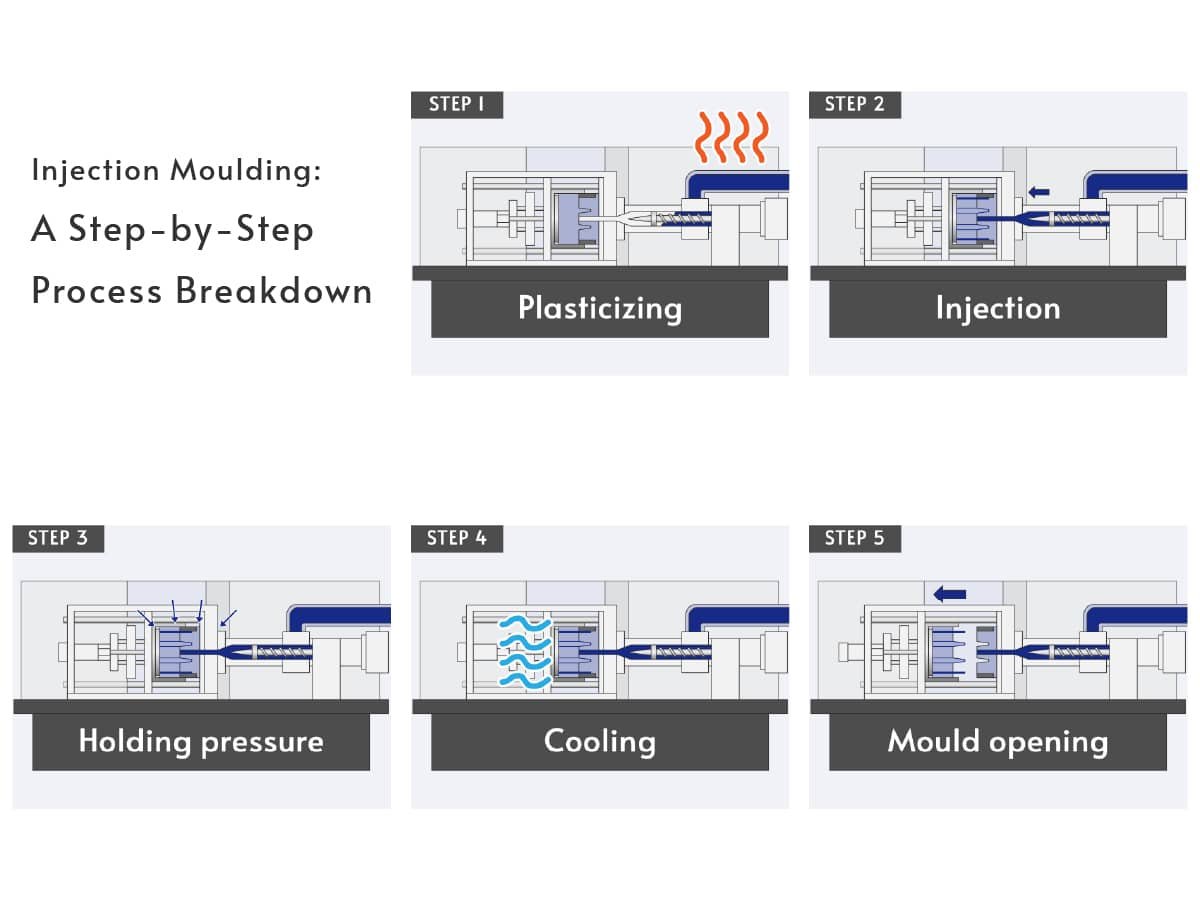

How Does Plastic Injection Molding Work?

Injection molding is a process used to manufacture plastic parts by heating, shaping, and cooling thermoplastic resins. The process begins with feeding resin pellets into the machine’s barrel, where they are melted, compressed, and injected through the mold’s runner system. The molten plastic flows into the mold cavities while operators monitor factors such as filling pressure and temperature distribution to ensure defects or imperfections do not occur. Once the plastic solidifies, the mold opens, and ejector pins push the finished part out. The mold then closes to receive the next shot of molten plastic, repeating the cycle until the production batch is complete.

When to Use Low Volume Injection Molding Production?

Prototyping and Design Verification: When product designs are mature enough to require functional parts for real-world testing, low volume injection molding produces components with production-grade materials and finishes.

Market Testing: Launching a new product carries risks, but low volume plastic molding mitigates them by producing small batches for consumer feedback.

Small Batch Manufacturing: For startups, specialty products, or limited edition runs requiring between 100 and 10,000 parts, it offers substantial cost and lead time savings compared to traditional high-volume molding.

Niche Markets: Industries like medical devices, aerospace, and consumer electronics often require small quantities of specialized parts. Low volume injection moulding delivers precision and quality for these applications.

Custom and Tailored Components: When parts need frequent design changes or variants, low volume plastic molding supports flexible production without large sunk costs.

FAQ About Low Volume Injection Molding

You can choose from common plastics like ABS, polycarbonate, or nylon. Pick the one that suits how and where you’ll use your part, how strong it needs to be, and your budget.

Make sure your part has consistent wall thickness, includes draft angles for easy release, and avoids sharp corners or tight spots. Using standard dimensions whenever possible will also help reduce your costs.

3D printing is great for complex prototypes, but your parts may be weaker and less precise. Injection molding gives you stronger, more consistent parts that feel like production-quality.

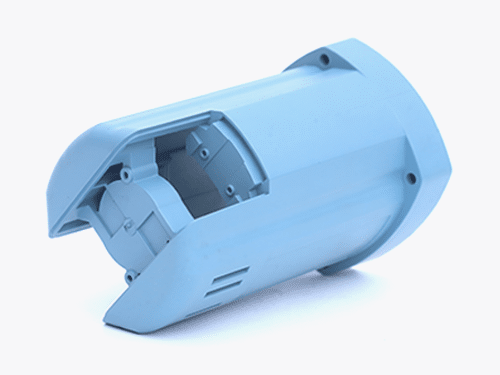

Low Volume Injection Molding Examples