On-Demand Manufacturing Service

Jiangzhi On-Demand Manufacturing

Jiangzhi’s on-demand manufacturing services provide flexible, scalable, and efficient production tailored to your specific needs. Whether you require small batch runs, rapid prototyping, or customized parts, we adjust production schedules and processes to match your project requirements.

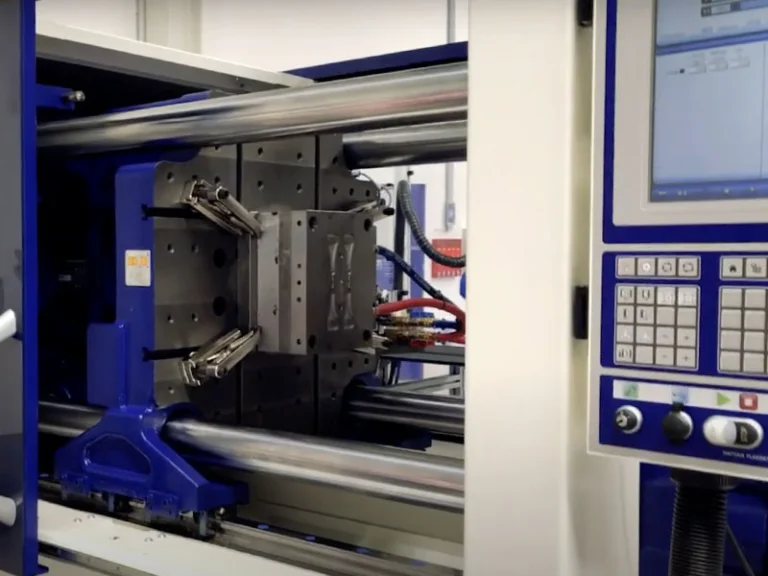

Our experienced team of engineers will provide you with comprehensive DFM analysis and plastic part design suggestions, covering the entire process of services from mold design, production processing, assembly, to surface treatment. From structural feasibility, material selection to manufacturing optimization, Jiangzhi, as a china injection molding supplier, helps you achieve the best final product that balances functionality, cost and efficiency.

Our On-Demand Manufacturing Services

Injection Molding Service

Compression Molding Service

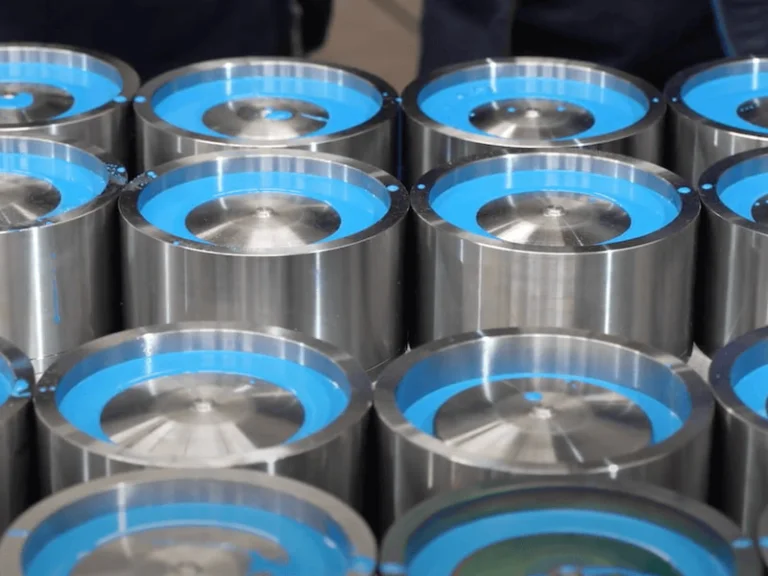

CNC Machining Service

Cast Molding Service

How to Work with Us?

Upload a CAD File

Quote & Design Analysis

Manufacturing Begins

Parts Shipped

On-Time

Why Choose Jiangzhi On-Demand Manufacturing?

High Precision & Consistent Quality

Fast Turnaround & Flexible Capacity

In-house tooling and agile workflows enable us to deliver T1 prototypes in as fast as 2 weeks, and scale to meet low-volume manufacturing needs efficiently.

Expert Engineering Support

One-Stop Prototyping & Small-Batch Solution