Design for Manufacturability

- Quality Manufacturing Starts with Good Design

- Decrease Tooling Rework, Reduce Cost

- Avoid 50% Injection Molding Defects

- Contract Manufacturer Engineering Service

A Well-Executed Injection Molding DFM Report Helps You

Design for Manufacturability(DFM), also known as design for manufacturing, is an essential analytical tool used in the plastic injection molding process to evaluate and optimize product designs for efficient, reliable, and cost-effective production. Even when you're in a rush to launch, skipping the injection molding DFM report can cost you more in the long run. It may lead to design errors, delays, and quality issues that outweigh any time saved.

Confirms the feasibility of the product design for manufacturing

Optimizes the mold design plan for quality and cost-efficiency

Shortens the product development cycle by identifying issues early

Enhances collaboration between design and production teams

What Design for Manufacturability Can Tell You

We make an injection molding DFM report to ensure the product design is suitable for manufacturing and to identify potential issues or areas for improvement before production begins. Following shows a simple design as an example, you will get to know that information you can get from a DFM report.

1. General Description

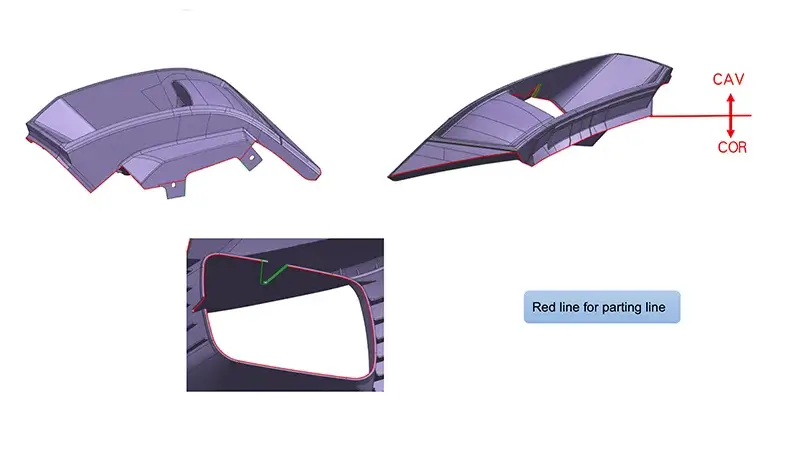

2. Parting Lines

Examines the location of the parting line (where the two halves of the mold meet).

Parting lines are usually located on the edges of the molded parts. However some lines may located around the middle of the part due to geometry structure.3. Gate Locations

Evaluates the optimal locations for gates (inlets for injecting molten plastic into the mold cavity).

The injection molding gate in the DFM report isn't the only option. You can inform us if it affects cosmetics or functionality. The gate type determines the way to produce and even the mass production cost.

4. Lifters and Sliders

Assesses the need for and placement of lifters (movable mold components) and sliders (side-action components).

Lifter and silder are injection mold components to create undercuts.

5. Ejector Pin Marks

Analyzes the placement of ejector pins used to remove the molded part from the mold.

The ejector marks can not be removed due to the process of injection molding.

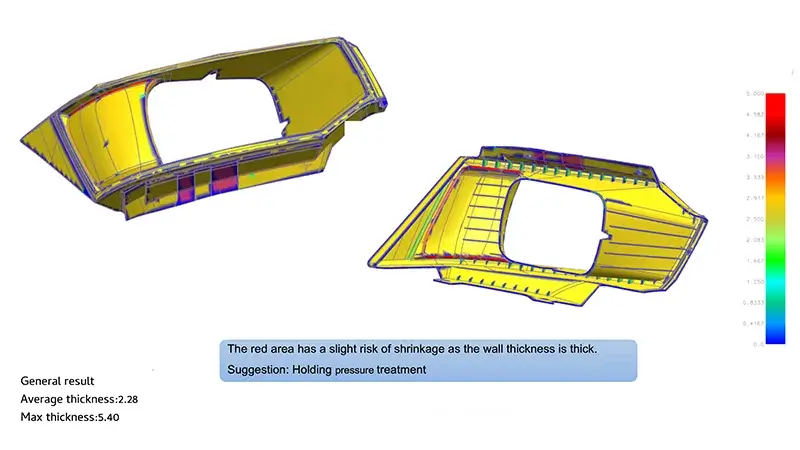

6. Rib and Wall thickness

Checks for uniform wall and rib thicknesses to prevent warping or other defects.

The thickness of the ribs should be about 60% of the wall thickness, avoid uneven wall thickness, avoid thin wall area as much as possible.7. Draft Angle

Evaluates draft angles (tapers) to ensure injection molded part easy release from mold cavity.

Sometimes it will slightly change the design of the original product.

8. Problems & Solutions

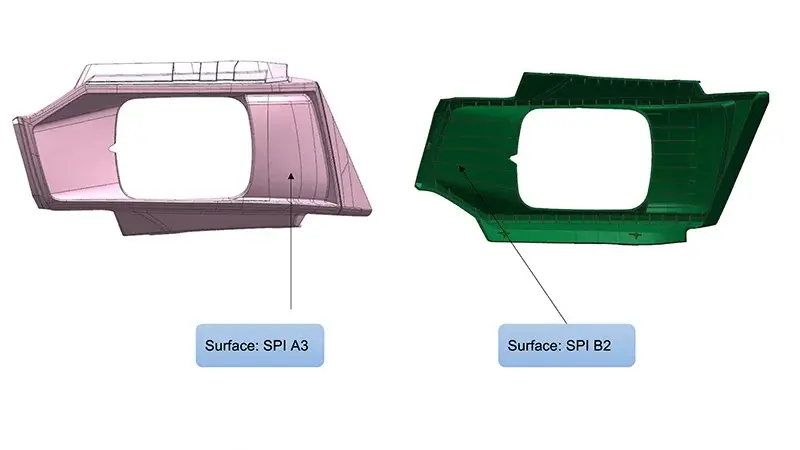

9. Surface Finish Requirements

Specifications for the desired surface finish, which can have multiple finishes on a single part. Also define if there is any engraving or raised areas.

Normally we suggest determine texture or polish surface before machining the molds as the draft may not machined again as specified texture.

Custom Contract Manufacturing Capability

DFM

Capability

Upload Your CAD Files – Receive A DFM Analysis

FAQs About DFM Injection Molding

Mold Flow Analysis is a simulation that shows how plastic will flow inside the mold. It helps me spot issues like warping, sink marks, short shots, or weld lines before production. Including it in a DFM report helps avoid defects and costly mold changes later.

Usually 1–3 days, depending on the complexity of your part.

Yes, that’s the best time to make changes—before the mold is made.

No, it actually helps me save by preventing costly rework or delays.

Even simple parts can have issues. I prefer to catch them early rather than fix them later.

Absolutely. We provide practical suggestions to make your design easier and more cost-effective to produce.

Popular Post

What Is Co-Injection Molding? A Complete Beginner’s Guide

Co-injection molding is a process used in plastic manufacturing to produce parts with multiple layers of material. This method allows

Threaded Inserts for Plastic Injection Molding: Types, Methods, and Design Tips

Threaded inserts for plastic injection molding are essential in industries that require durable, reusable fasteners in plastic components. Threaded inserts

Understanding Compression Molding Products: Balancing Strength and Cost

In the world of manufacturing, how you make a product matters. Among many methods, Compression Molding is a key technique.