In modern manufacturing, two processes dominate prototyping and low- to medium-volume production: CNC machining and 3D printing. People frequently ask which method is better for their specific part. The answer depends on quantity, geometry, material requirements, tolerances, and lead time. This article will provide a comprehensive comparison of CNC machining vs 3D printing.

Basic Principles of CNC Machining vs 3D Printing

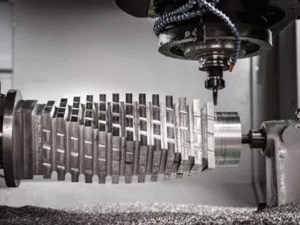

CNC Machining service (Computer Numerical Control machining) is a subtractive manufacturing process where a computer-controlled machine tool removes material from a workpiece to create the desired part. The process starts with a solid block of material, and through precise cutting, drilling, or milling, the final shape is produced. CNC machining is known for its high precision, ability to work with various materials (including metals, plastics, and composites), and its capability to create complex geometries with tight tolerances.

3D printing is an additive manufacturing process. It builds parts layer by layer from a digital file. Technologies include FDM (fused deposition modeling), SLA (stereolithography), SLS (selective laser sintering), and metal processes such as DMLS (direct metal laser sintering) or binder jetting. This allows for the creation of parts with intricate geometries and internal structures that would be challenging or impossible to achieve with traditional machining.

Advantages and Disadvantages of CNC Machining vs 3D Printing

CNC Machining Advantages

- Precision and Accuracy: CNC machining can produce parts with extremely tight tolerances, often within a few micrometers. This makes it ideal for high-precision industries like aerospace, automotive, and medical device manufacturing.

- Material Options: CNC machining supports a wide range of materials, including metals, plastics, and ceramics, making it versatile for various applications. It can handle tough materials like titanium, stainless steel, and aluminum, which are often required in demanding industries.

- Surface Finish: The finish produced by CNC machining is typically smooth and clean, often requiring little to no post-processing. This is particularly advantageous when producing parts that need to mate with other components or meet strict aesthetic requirements.

- Production Volume: CNC machining is ideal for mass production or medium-to-large batch production. Once a CNC machine is set up, it can produce a large number of identical parts quickly and consistently.

CNC Machining Disadvantages

- Material Waste: Because CNC machining is a subtractive process, a significant amount of material is removed and discarded. This can result in higher material costs, especially when dealing with expensive raw materials.

- Design Limitations: Although CNC machining is highly precise, it can be limited when it comes to producing highly complex geometries. For parts with intricate internal structures or organic shapes, CNC machining may not be the best solution.

- Ineffective Setup Time for Low Quantities: CNC machining requires significant setup time, including programming, tool changing, and part fixturing. This can be a disadvantage when producing small quantities or prototypes.

3D Printing Advantages

- Design Flexibility: 3D printing offers nearly unlimited design freedom. Complex geometries, internal channels, and customized shapes can be produced without the need for specialized tooling. This makes 3D printing particularly advantageous for rapid prototyping and custom manufacturing.

- Material Efficiency: Unlike CNC machining, which removes material, 3D printing uses only the material needed to create the part. This results in less waste, making it more environmentally friendly and cost-effective for low-volume production.

- Faster Prototyping: 3D printing can significantly reduce the time required to create a prototype. Parts can often be printed overnight, allowing for quick iterations in the design phase, which is essential in industries like product development and design verification.

- Lower Setup Costs: There are no complex setup procedures or expensive tooling requirements with 3D printing. Once the digital model is ready, the printer simply starts the production process. This makes it a cost-effective solution for small-scale and custom production.

3D Printing Disadvantages

- Low Surface Finish and Accuracy: 3D printing generally falls short of CNC machining in surface finish and dimensional accuracy. Parts often require post-processing to achieve a smooth surface and precise fit, especially when dealing with fine details or tight tolerances.

- Material Limitations: While the range of materials available for 3D printing is growing, it still does not match the variety or performance characteristics of CNC machining materials. For example, 3D printed metals may not have the same strength, durability, or heat resistance as those machined using traditional methods.

- Slow Production for Large Volumes: 3D printing is fast for prototypes and small runs, but it is generally slower than CNC machining when it comes to mass production. Printing large volumes of parts is not cost-effective compared to traditional manufacturing processes.

Ideal Use Cases for CNC Machining and 3D Printing

CNC Machining Applications

- Aerospace: High-precision components such as turbine blades, brackets, and structural elements that must meet exacting standards for strength, weight, and performance.

- Automotive: Engine components, transmission parts, and custom tooling that require high strength and tight tolerances.

- Medical Devices: Components like surgical instruments, orthopedic implants, and prosthetics, which need precise geometries and smooth finishes.

- Defense: Parts that must withstand extreme environments and mechanical stresses, such as military vehicle components and weapon systems.

- Heavy Industry: Components that experience high mechanical stress, like gears, pumps, and valves.

3D Printing Applications

- Prototyping: 3D printing is the best choice for quickly creating functional prototypes, allowing for fast iteration and design validation.

- Complex Geometries: The parts have intricate, complex designs that would be difficult or impossible to machine (such as lattice structures or internal channels).

- Low-Volume Production: Low-volume production, especially when the tooling costs for CNC machining would be prohibitive.

- Custom Parts: For industries like fashion or medical, where customized parts or one-off designs are common, 3D printing allows for cost-effective and quick production without the need for expensive molds or tooling.

- Specific Components: Lightweight, highly customized parts like brackets, enclosures, or turbine blades with complex geometries that would be difficult to manufacture through traditional methods.

CNC Machining vs 3D Printing: How to Choose the Right Technology

When deciding between CNC machining vs 3D printing, the choice depends on several factors, including the complexity of the part, material requirements, production volume, and desired surface finish.

- Part Complexity: If the part has a simple, regular shape, CNC machining may be the better option. However, if the part requires intricate geometries or internal structures, 3D printing provides a clear advantage.

- Material Requirements: For parts that require high-performance materials or exceptional strength, CNC machining is typically preferred. 3D printing has limitations in some metals and polymer materials.

- Production Volume: CNC machining excels in mass production or medium-volume runs due to its speed and repeatability once set up. However, for low-volume or prototyping needs, 3D printing offers faster turnaround times and lower setup costs.

- Cost Considerations: While CNC machining may have a higher upfront cost due to tooling and setup, the per-unit cost decreases with higher production volumes. 3D printing, on the other hand, is better suited for low-volume runs, where tooling costs are not a concern.

- Precision: When it comes to precision, CNC machining typically outperforms 3D printing. CNC machines can achieve tight tolerances with micron-level accuracy. 3D printing typically achieves tolerances of +/- 0.1 mm, which may not be sufficient for high-precision applications.

- Surface Quality: CNC-machined parts can be finished to a very high standard, offering smooth surfaces that meet the stringent requirements for functional and aesthetic parts. 3D printing parts often exhibit a rougher surface finish and require post-processing.

Conclusion

CNC machining and 3D printing are complementary rather than competitive technologies. The most successful teams use both: 3D printing for rapid iteration and complex geometries, CNC machining for precision and final production. Many projects now follow a hybrid path that delivers the best outcome. Jiangzhi provides professional CNC machining services, offering high-quality solutions tailored to your specific manufacturing needs.