Fiberglass compression molding is a manufacturing method used to produce composite parts with glass fibers and resin. Thanks to its ability to create strong and lightweight components efficiently, this process is widely used across multiple industries. In this article, we explore what fiberglass compression molding is.

What is Fiberglass Compression Molding?

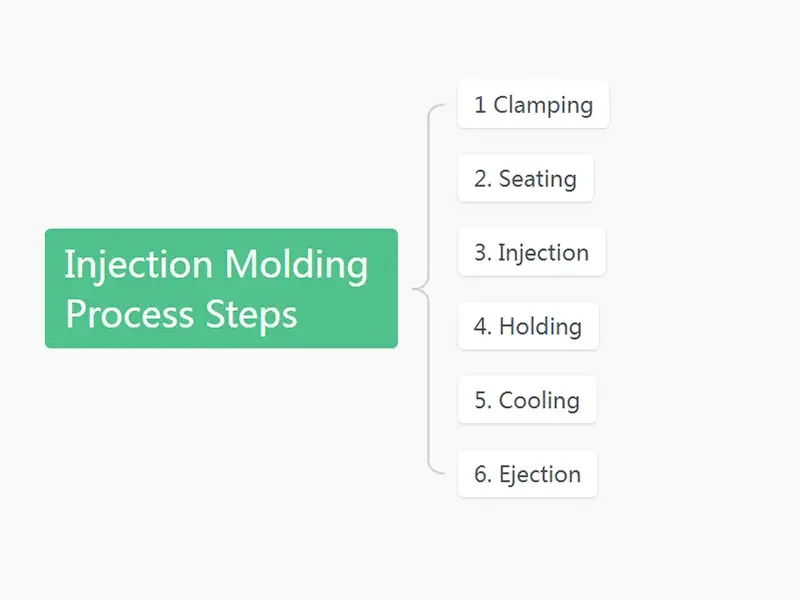

Fiberglass compression molding is a technique where fiberglass reinforcements and resin are combined in a mold under heat and pressure to create composite parts. The workflow for fiberglass compression molding includes several steps.

First, the material is prepared by cutting or weighing the fiberglass compound. These materials contain glass fibers mixed with resin, fillers, and additives. Second, the prepared material is placed into the lower half of a matched metal mold. The mold is then closed, and pressure is applied while heated. Third, the part remains under pressure for a curing period.

Pre-Treatment and Layup Considerations for Fiberglass Compression Molding Materials

Fiberglass reinforcements, such as rovings or mats, are typically chopped to 40–50 mm for SMC or BMC and treated with sizing agents like silane to improve resin adhesion. The resin mixture, including catalysts and fillers, should have the proper viscosity to ensure smooth flow during molding.

Fiberglass must be stored in dry conditions to prevent water absorption, which can cause voids or weaken the final part. Accurate weighing of the material is necessary to match the mold volume, preventing underfill or excessive flash. For SMC, sheets are cut to fit the mold; for BMC, the material is portioned as a bulk mass.

During layup, materials should be evenly distributed in the mold. For complex shapes, layers should cover all areas with a slight overfill to account for compression. Tools like rollers or brushes help spread the material and remove air pockets.

Characteristics and Advantages of Fiberglass Compression Molding

Fiberglass compression molding has distinct characteristics that make it suitable for manufacturing composite parts. Below, each characteristic is outlined with its corresponding benefit.

Reproducibility and Consistency

The process ensures consistent part quality across production runs. Fiberglass compression molding uses matched-metal molds and controlled conditions to maintain uniform dimensions and mechanical properties, minimizing variations due to operator input.

Fluidity

Fiberglass moulding allows materials to flow into thin walls and intricate geometries during compression. The combination of SMC or BMC with 40-50 mm fibers enables the resin to fill complex mold cavities under pressure, ensuring detailed shapes are achieved without voids.

Low Shrinkage

The process results in minimal material contraction during curing. Fiberglass compression molding produces parts with accurate dimensions and smooth surface finishes, often requiring little to no post-processing.

Moderate Operating Conditions

Fiberglass compression molding operates at moderate temperatures and pressures compared to metal-forming techniques. This reduces energy consumption and wear on equipment, making the process sustainable for medium-volume production. It also allows integration of inserts, enhancing part functionality.

High strength-to-weight ratios

high strength-to-weight ratios, as glass fibers provide robust reinforcement, reducing component weight by up to 40% compared to metals.

Production Efficiency

Production efficiency is achieved with cycle times under 5 minutes, supporting hundreds of parts daily. Labor costs are low due to automation potential, and material waste is minimized through precise mold charging.

Disadvantages and Challenges of Fiberglass Compression Molding

Fiberglass compression molding presents certain disadvantages and challenges that must be addressed in manufacturing.

High Investment in Molds and Equipment

The molds used in fiberglass compression molding are typically made from steel, requiring a high investment. Hydraulic presses and heating systems add to the equipment costs. Custom molds may involve complex tooling processes and design iteration, raising initial costs, especially for low-volume production runs.

Strict Process Control Requirements

Since the quality of fiberglass compression-molded parts depends on exact temperature, pressure, and timing profiles, stringent process control is mandatory. Deviations can result in incomplete resin curing, warping, or dimensional inaccuracies. Maintaining consistent resin flow and fiber wetting during the rapid compression phase is particularly challenging, requiring careful monitoring and sometimes specialized automation technology.

Material Flowability Issues

The viscosity of SMC or BMC in fiberglass moulding can limit flow in thin sections or sharp corners. If the material does not flow properly, voids or uneven fiber distribution may result. Pre-heating the material can help, but it requires additional steps and testing to optimize. Fiber tangling in detailed areas further complicates the process.

Challenges with Dimensions and Wall Thickness

Maintaining uniform wall thickness is difficult in fiberglass compression molding, especially for parts with variations greater than 3 mm. Thicker sections may cure unevenly, leading to warping or internal stresses. Large parts amplify these issues, as even cooling becomes harder to control.

Fiberglass Compression Molding Product

Fiberglass compression molding is applied in various products.

- Automotive Components: Lightweight bumpers, body panels, and structural brackets benefit from fiberglass’s strength and corrosion resistance, contributing to vehicle weight reduction and enhanced fuel economy.

- Aerospace Parts: Structural elements exposed to high mechanical stress and temperature fluctuations are effectively manufactured using this process, leveraging the combination of durability and lightness.

- Consumer Goods and Infrastructure: Sports equipment shells, durable outdoor furniture, and construction panels demonstrate fiberglass moulding’s versatility and cost-efficiency.

Conclusion

Fiberglass compression molding provides a method for creating composite parts with fiberglass reinforcements. The method offers numerous benefits, such as production efficiency, reproducibility, etc. Cooperating with a professional manufacturer will result in successful compression molding. Jiangzhi has experience in fiberglass compression molding service. Welcome to contact Jiangzhi and get a custom fiberglass compression molding solution.