In mechanical design and manufacturing, edge treatments such as fillets and chamfers play a significant role in the performance and production of parts. These features affect structural integrity, assembly processes, safety, and cost efficiency. This article explores the distinctions between fillet vs chamfer, their respective advantages and disadvantages, and provides guidance on selecting the most suitable treatment for various applications.

What is a Fillet?

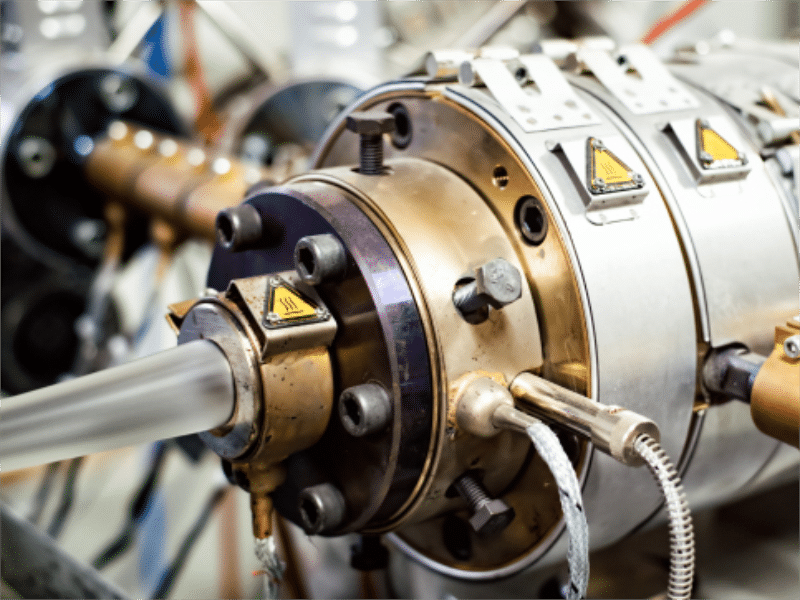

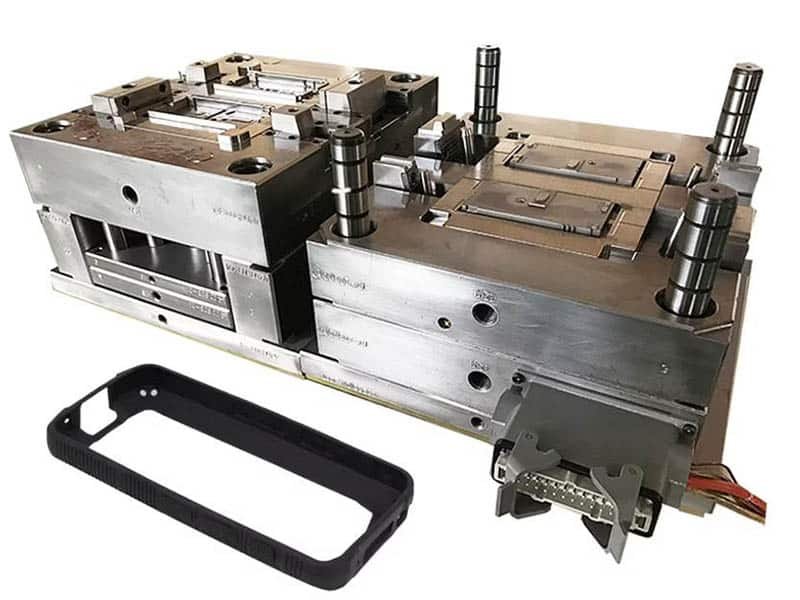

A fillet refers to a rounded transition between two intersecting surfaces, typically applied at the corners or edges of a part. It is used to create a smooth, curved edge that can help distribute stress more evenly and enhance fluid flow, making it particularly useful in various manufacturing processes such as injection molding. In technical terms, it replaces a 90-degree angle with a smooth arc. Fillets are specified by their radius value, such as R1.0, indicating a 1.0 mm radius curve.

Advantages of Fillet

- Improves stress distribution by reducing concentration at corners, which enhances fatigue resistance in parts under cyclic loading.

- Facilitates better material flow in processes like injection molding, minimizing defects such as voids or sink marks.

- Enhances safety by eliminating sharp edges that could cause injury during handling.

- Provides a smoother surface finish, which is beneficial for aesthetic purposes in consumer products.

- Increases part strength in thin-walled components by avoiding notches that propagate cracks.

Disadvantages of Fillet

- Requires more complex tooling in machining, such as ball-end mills, which can increase cycle times.

- Adds to material removal in CNC operations, potentially raising costs for high-volume production.

What is a Chamfer?

A chamfer is an angled cut at the edge of a part, typically formed at a 45-degree angle, although other angles are possible depending on the design specifications. Chamfers are primarily used to remove sharp edges or to facilitate assembly, especially for parts that will be bolted or screwed together. It is denoted by its size and angle, for example, C1.0 x 45°, meaning a 1.0 mm cut at 45 degrees.

Advantages of Chamfers

- Simplifies deburring by removing burrs and sharp edges efficiently during manufacturing.

- Aids in assembly by providing lead-in surfaces for easier insertion of components like bolts or pins.

- Reduces machining time as it can be produced with standard end mills or chamfer tools.

- Lowers production costs in large batches due to straightforward geometry.

- Improves edge protection in sheet metal parts, preventing damage from impacts.

Disadvantages of Chamfers

- Chamfers do not alleviate stress concentration points and may even contribute to localized stress under certain conditions, potentially affecting the part’s durability.

- Chamfers are not suitable for applications requiring smooth fluid flow, as their angular edges may disrupt the material’s movement.

Key Differences Between Fillet and Chamfer

The decision between using a fillet ora chamfer hinges on the part’s intended function, manufacturing process, and structural requirements. Here are some of the key differences:

Shape

Fillet forms a concave or convex arc that blends surfaces seamlessly. This curved profile distributes forces evenly across the transition area.

Chamfer produces a flat, angled face that truncates the corner linearly. The result is a polygonal edge rather than a smooth curve.

Function

Fillet is primarily used for stress relief and improving the flow of materials in injection molding or similar processes. It is also beneficial for enhancing the part’s strength by distributing the load more evenly across the surface.

Chamfer is commonly used for assembly purposes. They facilitate easier alignment and installation of parts that need to be bolted or screwed together. They also reduce sharp edges that could cause injury during handling.

Manufacturing Constraints

Fillets often require specialized tools and paths. In CNC milling, ball-end mills follow curved trajectories, which can extend processing time and wear tools faster.

Chamfers use simpler straight cuts with chamfer mills or countersinks, making them quicker and less expensive to produce.

Angle Limitations

Fillets do not have strict angle limitations; they can be applied with a variety of radii, depending on the design needs.

Chamfers typically have a defined angle, commonly 45 degrees, although this can be adjusted in some applications to meet specific design requirements.

To summarize the fillet vs chamfer comparison:

| Aspect | Fillet | Chamfer |

|---|---|---|

| Shape | Curved arc | Angled flat face |

| Function | Stress relief, flow improvement | Assembly guide, deburring |

| Mold Storage | Forever | |

| Manufacturing | Complex tooling, longer time | Simple tools, faster production |

| Angle/Radius | Radius-based (e.g., R2.0) | Angle-based (e.g., 45°) |

| Cost Impact | Higher for precision work | Lower for volume production |

How to Choose Between Fillet and Chamfer?

Selecting between fillet and chamfer requires evaluating the part’s application, material, and production method. Below are guidelines for common scenarios.

When to Use Fillet?

Fillets are preferred in structural components where durability is critical. For instance, in load-bearing brackets or frames, a fillet reduces stress at joints, extending service life. In injection-molded parts, fillets promote uniform plastic flow, preventing warping or incomplete fills. They are also suitable for products requiring a polished appearance, such as electronic housings, where smooth edges enhance user experience. Additionally, in aerospace or automotive parts, fillets maintain integrity under vibration.

When to Use Chamfer?

Chamfers are effective for features involving assembly or maintenance. In bolt holes, a chamfer at the entrance facilitates screw insertion and prevents thread damage. For machined components like shafts or gears, chamfers guide mating parts during installation. They are commonly used in deburring operations on metal sheets to remove sharp remnants from cutting. In high-volume CNC production, chamfers minimize tool changes and cycle times, controlling costs.

Design Considerations and Optimization Tips

Effective use of fillets and chamfers involves practical rules to avoid common errors.

- Maintain consistent sizes within a part to simplify programming and inspection. For fillets, ensure the radius is at least 0.5 times the wall thickness in thin sections to prevent weakness. In chamfers, stick to 45-degree angles unless a different slope is necessary for clearance.

- Consider tool limitations when manufacturing. Fillet radii should not exceed available mill sizes to avoid multiple passes. Chamfer depths must account for material thickness to prevent breakthrough.

- In CAD, apply fillets early in modeling to integrate them into the geometry. For chamfers, add them post-feature to adjust precisely.

- Optimize for manufacturing. Larger fillets reduce tool stress but increase material use. Smaller chamfers save time but may require finishing.

- Test prototypes. Simulate loads to verify fillet vs chamfer performance.

Conclusion

Understanding fillet vs chamfer enables better part optimization. Fillets provide strength and flow benefits, while chamfers offer assembly ease and cost savings. Incorrect selection can lead to increased production time, higher costs, or reduced part durability. Jiangzhi specializes in custom parts, offering expertise in these features for various industries. Contact us for tailored solutions.