As a plastic injection molding manufacturer, we understand that the quality and efficiency of every molded part start with what’s inside the mold—its Injection mold components. From the mold base and cavity to advanced elements like sliders and hot runners, each component must be precisely engineered and properly maintained to ensure reliable performance, reduced cycle times, and long mold life.

In this article, we provide an in-depth look at the key injection mold parts and their functions, design considerations, and how smart choices in materials and layout can significantly impact your production results. Whether you’re seeking to optimize existing tooling or develop a new mold, understanding these components is essential to achieving consistent, high-quality plastic parts at scale.

Core Components of an Injection Mold

The heart of any injection mold lies in its core molding components, which work together to shape and produce plastic mold parts. Let’s explore the primary parts and their functions.

Mold Base

The mold base serves as the structural backbone, holding all mould parts in precise alignment. It withstands the intense clamping forces during injection, ensuring stability.

A well-designed mold base prevents defects like flash or misalignment, directly contributing to the quality of injection moulded parts. Its robust construction is critical for high-volume production, where consistency is paramount.

Mold Cavity and Core

The mold cavity and core are the plastic mold components that define the shape of the final part. The cavity forms the external surface, while the core shapes internal features, such as holes or recesses.

These components require high-precision machining to achieve tight tolerances, ensuring injection moulded plastic components meet exact specifications. Their accuracy determines dimensional precision and surface finish, making them pivotal for quality.

Sprue, Runners, and Gates

The delivery system for molten plastic consists of the sprue bushing, runners, and gates. The sprue bushing is the main channel connecting the injection machine’s nozzle to the mold, guiding plastic into the system. Runners distribute the material to multiple cavities, while gates control its entry, ensuring uniform flow.

Optimized design of these mould parts minimizes defects like short shots or weld lines, enhancing the consistency of plastic mold parts. Thoughtful runner and gate sizing also reduces material waste and cycle time.

Ejector System

The ejector system removes solidified parts from the mold without damage. Types of ejector in mould include pins, sleeves, and plates, each chosen based on part geometry. For example, ejector pins are common for flat surfaces, while sleeves suit cylindrical features.

Proper placement prevents surface marks or deformation, preserving the quality of injection moulded plastic components. Maintenance-friendly designs, like easily replaceable pins, reduce downtime and upkeep costs.

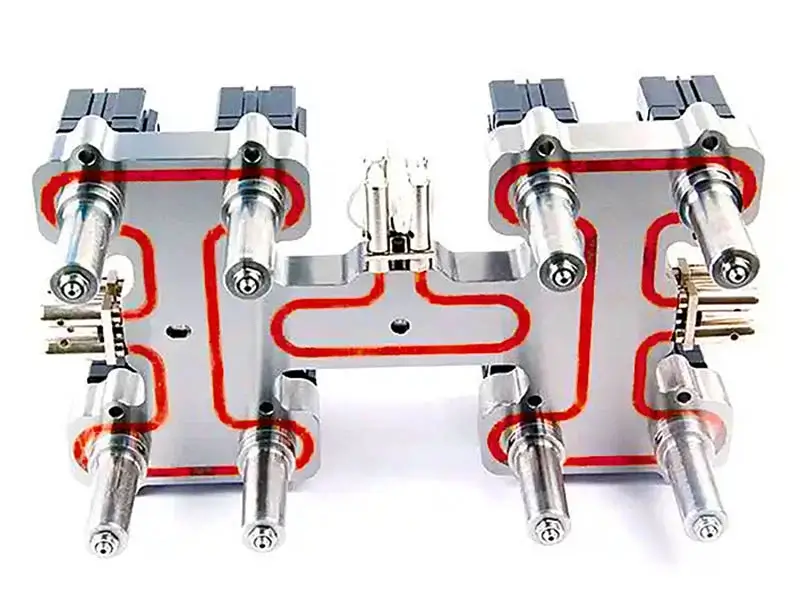

Cooling System

The cooling system regulates mold temperature through channels that circulate coolant, typically water. Uniform cooling is essential to prevent warping, shrinkage, or internal stresses in plastic mold parts.

Optimized channel layouts shorten cycle times and improve part strength, making this system a key factor in both efficiency and quality.

Venting System

Venting allows trapped air and gases to escape during injection, preventing defects like burns, voids, or incomplete filling. Small vents, typically 0.01–0.05 mm, are strategically placed to avoid flash. Effective venting ensures injection moulded parts are free of imperfections, maintaining high standards.

Guide Pins and Bushings

Guide pins and bushings maintain precise alignment between mold halves during opening and closing. This precision prevents misalignment, ensuring consistent dimensions in injection moulded parts. Their durability is crucial for long-term performance.

Advanced Injection Mold Components for Complex Designs

For intricate injection moulded parts with complex geometries, advanced mould parts are essential. These components enable the production of plastic molded parts with complex features.

Sliders and Lifters

Sliders and lifters address complex part features like undercuts or side details. Sliders move laterally to release side features, while lifters (also called angle pins) handle internal undercuts during ejection.

These molding components ensure smooth demolding without damaging delicate injection moulded plastic components, making them indispensable for intricate designs.

Hot Runner System

A hot runner system keeps plastic molten within the mold, eliminating the need for solidified runners. This reduces material waste and cycle times, improving efficiency for high-volume production of plastic mold parts. Hot runners also enhance part quality by ensuring consistent flow and minimizing defects like weld lines.

Interlocks

Interlocks, or anti-misalignment features, ensure precise alignment between mold halves, especially in complex molds with multiple moving parts. By preventing misalignment, interlocks maintain dimensional accuracy and reduce wear on mould parts, contributing to the longevity and quality of injection moulded parts.

Support Pillars

Support pillars provide additional structural reinforcement in molds for complex or large plastic mold components. They prevent deflection under high clamping forces, ensuring stability and consistent part quality, particularly in multi-cavity or high-pressure applications.

Design and Material Considerations for Injection Mold Components

The design and material choices for injection mould parts significantly influence performance, quality, and cost. Here’s how these factors come into play.

Processing Accuracy

Components like cavities and cores demand tight tolerances, achieved through techniques like CNC machining, EDM, or polishing. High processing accuracy ensures injection moulded plastic components meet exact specifications, minimizing defects and rework.

Cooling Channel Layout Optimization

Cooling channels are strategically placed close to high-heat areas, following part contours to ensure uniform temperature control. This layout reduces cycle times, prevents defects like warping, and enhances the strength of injection moulded parts, making it a critical design focus.

Gate Design

Gates control the entry of molten plastic into the mold cavity. They are typically placed near thicker sections or non-visible areas to reduce gate marks and ensure smooth, even filling. The size and type of gate—such as edge, pin, or hot tip—should align with part geometry and material flow requirements for optimal results.

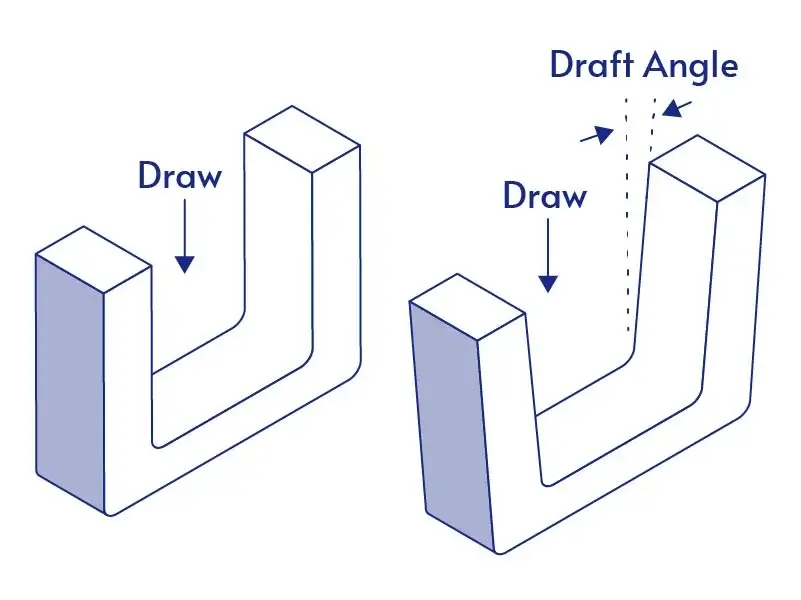

Draft Angle Design

Draft angles facilitate the easy ejection of parts from the mold. Insufficient draft can lead to sticking, part damage, or longer cycle times. Draft angles should be customized based on the material shrinkage and part geometry, typically ranging from 0.5° to 5°. Deep or textured surfaces may require larger angles.

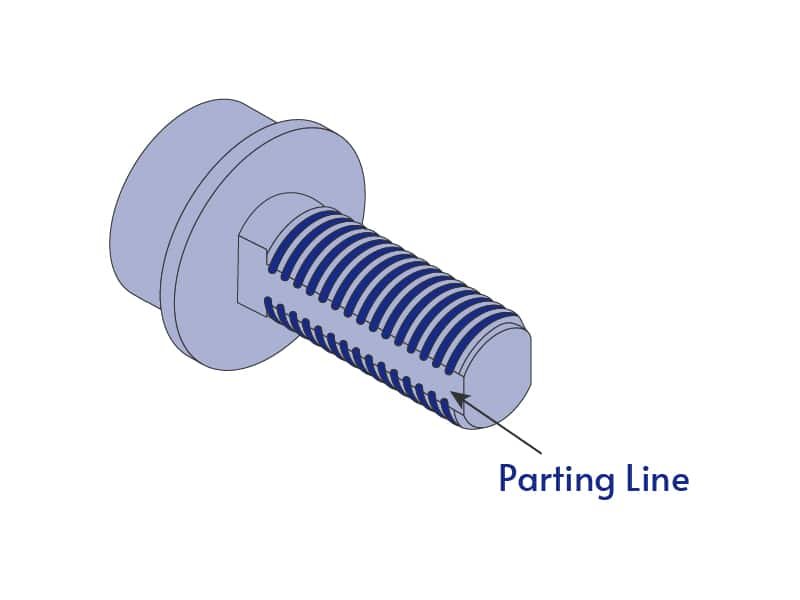

Parting Line Design

Parting lines define where the two halves of the mold separate. A well-designed parting line avoids visible surfaces to minimize flash and visual defects. In complex geometries, slides or interlocks are often used to maintain alignment and prevent mismatch, ensuring precision in multi-cavity or intricate molds.

Material Selection

Molding components are typically made from hardened steel, pre-hardened steel, or aluminum, chosen for durability, wear resistance, and thermal conductivity. Material choice also balances cost and performance. In the below table, we briefly overview the material selection for different injection mold parts.

| Component | Suitable Materials | Considerations |

|---|---|---|

| Mold Base | S50C Steel, P20 Steel, Aluminum (7075) | S50C for cost-effective molds, P20 for durability, aluminum for prototypes. |

| Cavity and Core | Hardened Steel (H13, 420SS), P20 Steel | Hardened steel for high precision and wear resistance. |

| Sprue Bushing | Hardened Steel (H13, D2) | Durable materials resist thermal stress and abrasion. |

| Gates and Runners | Hardened Steel (H13), P20 Steel | Polished steel ensures smooth flow and minimizes wear. |

| Ejector System | Hardened Steel (SKD61, H13), S7 Steel | Types of ejector in mould require wear-resistant materials for longevity. |

| Cooling Channels | Stainless Steel, Copper Alloys (BeCu) | Copper alloys enhance thermal conductivity for efficient cooling. |

| Guide Pins/Bushings | Hardened Steel (H13, SKD11) | High-strength materials resist wear during repeated mold cycles. |

| Support Pillars | P20 Steel, S50C Steel | Strong materials prevent deflection under pressure. |

| Sliders and Lifters | Hardened Steel (H13, D2) | Durable and wear-resistant materials ensure smooth movement and longevity. |

| Interlocks | Hardened Steel (D2, SKD11) | Precision-machined, durable materials ensure tight alignment. |

Injection Mold Lifespan and Maintenance

A injeciton mold’s lifespan, typically ranging from 100,000 to over 1 million cycles, depends on its design, material quality, and maintenance, directly impacting the cost-effectiveness of producing plastic mold parts. High-quality mould parts and regular upkeep extend durability, with wear commonly occurring in gates, ejector systems, and cavity surfaces due to abrasion or thermal stress. Daily maintenance, including cleaning plastic residues, lubricating moving parts, and inspecting cooling channels, ensures reliable performance of molding components. Signs of failure, such as flash, sticking parts, or inconsistent cycle times, require prompt action like adjusting clamping force or replacing worn mould parts to prevent downtime and defective injection moulded parts.

Why Understanding Injection Mold Components Matters

The design and condition of mould parts directly influence the quality of injection moulded plastic components. Well-designed runners, gates, and cooling systems promote consistency, and effective ejector and venting systems prevent defects like voids or burns. A deep understanding of types of injection mold components unlocks significant benefits for manufacturers:

- Improved Product Quality: Optimized mould parts deliver precise, consistent, and defect-free injection moulded parts.

- Shorter Development Cycles: Well-designed molds reduce testing and iteration time, speeding up production.

- Cost Reduction: Efficient designs and proactive maintenance minimize waste and downtime, lowering costs for plastic mold components.

- Extended Mold Lifespan: Depend on different injection mold components choose the suitable aterial and right care maximize the durability of mould parts.

Conclusion

The mould parts and functions in an injection mold are the backbone of high-quality, efficient production. From the mold base to advanced components like sliders, hot runners, and interlocks, each part plays a critical role in shaping injection moulded plastic components. By prioritizing thoughtful design, high-quality materials, and proactive maintenance, manufacturers can achieve precise, consistent parts while minimizing costs and extending mold life. Jiangzhi is a on demand manufactring company providing one-stop injection molding service. Cooperate with our experienced team, optimizing the design and strict quality control, we ensure meet the needs of your injection molding project.

FAQ About Injection Mold Components

Injection molds are made through a process of design, precision machining, assembly, and testing. The mold is tailored to match the exact specifications of your product, ensuring high-quality and efficient production.

Mold components should be maintained based on usage. For high-volume molds, maintenance is recommended every 50,000–100,000 shots. For lower-volume molds, maintenance should occur every 10,000–20,000 shots or 1–3 months, whichever comes first.

Standard mold components, such as guide pins and screws, can usually be reused across different molds. However, custom components like cavities and cores are typically designed for specific products and are not interchangeable.