Injection mold making is a cornerstone of modern manufacturing, enabling the production of high-precision, high-volume plastic parts across industries. With over four decades of hands-on experience, we understand that successful mold making is not just about shaping metal—it’s about combining engineering expertise, material science, and process control to achieve the highest quality results. In this guide, we share in-depth insights into the injection mold making process, covering everything from mold structure, design methods, material selection, to cost optimization and quality assurance. Whether you’re developing a prototype or planning for mass production, mastering these fundamentals is critical to your project’s success.

What is Injection Mold Making?

Injection mold making is the process of designing and manufacturing a mold used in injection molding—a manufacturing technique where molten plastic is injected into a mold cavity to form a part. This process is widely used for producing large volumes of consistent and complex plastic components.

Types of Injection Molds

There are several types of molds, each serving different purposes in plastic injection molding:

Single-Cavity Mold:

This mold creates one part per cycle. It’s ideal for simple parts or lower production volumes.

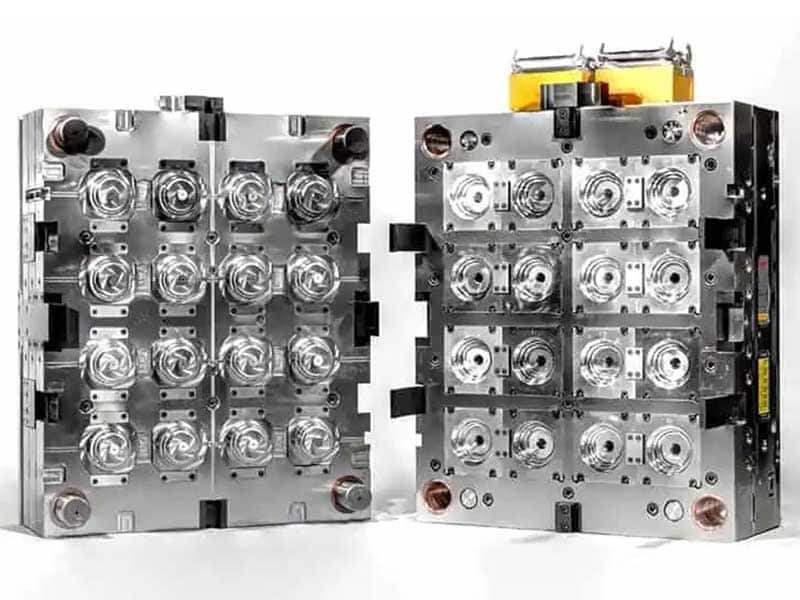

Multi-Cavity Mold:

Designed to produce multiple parts per cycle, these molds increase production efficiency and reduce per-part costs for high-volume runs.

Hot Runner Molds:

These molds maintain molten plastic within the system, reducing waste and improving cycle time efficiency.

Cold Runner Molds:

The opposite of hot runner molds, cold runner molds rely on the plastic cooling in the runner system, making them suitable for shorter production runs or parts requiring lower precision.

The Methods of Injection Mold Making

Injection mold making is a critical process in the manufacturing industry, especially for producing plastic parts at scale. It involves creating precise and durable molds used in injection molding machines to shape molten plastic into final products. Depending on factors such as production volume, part complexity, material type, and lead time, different mold-making methods can be employed. Each technique offers unique benefits in terms of cost, precision, durability, and speed.

1. Traditional Mold Making

Traditional injection mold making involves manual processes such as milling, grinding, drilling, and EDM (Electrical Discharge Machining). Skilled technicians use specialized tools and equipment to shape mold components from metal blocks—usually hardened steel or aluminum.

Advantages:

- Suitable for low to medium production runs

- Allows for detailed craftsmanship and manual adjustments

- Lower initial investment for simple mold structures

Limitations:

- Time-consuming for complex designs

- Higher labor costs

- Slower turnaround times compared to automated methods

This method is still relevant in industries where flexibility, customization, or lower production volume is required.

2. CNC Machining

CNC machining service has become a cornerstone in modern injection mold making. It uses computer-controlled machines to automate the cutting, drilling, and shaping of mold components with extreme accuracy.

Advantages:

- High precision and repeatability

- Ideal for complex and multi-cavity molds

- Reduced human error

- Faster and more scalable than traditional techniques

Applications:

CNC-machined molds are widely used in automotive, consumer electronics, and medical device industries where quality and consistency are critical.

3. Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is increasingly integrated into injection mold making, especially for prototyping and experimental mold designs. It involves building up mold forms layer by layer using materials such as photopolymers, thermoplastics, or metal powders.

Advantages:

- Rapid production of prototype molds

- Cost-effective for small batches or design testing

- Supports highly intricate geometries that are difficult to machine

Limitations:

- Lower strength and heat resistance (for plastic-printed molds)

- Not suitable for high-volume production

- Limited material choices for functional molds

3D printed molds are valuable during the early design stage, allowing engineers to validate and refine mold designs before committing to full-scale tooling.

4. Rapid Prototyping

Rapid prototyping in injection mold making is a methodology that combines digital design, simulation, and fast tooling techniques to shorten the product development cycle. It’s often used alongside 3D printing or soft tooling to evaluate design feasibility and functionality.

Advantages:

- Accelerates mold testing and optimization

- Reduces the risk of costly errors in full-scale molds

- Enables quick iterations based on real-time feedback

Typical Use Cases:

Rapid prototyping is ideal for R&D departments, startups, and product developers aiming to bring new products to market quickly without compromising quality.

Step-by-Step Injection Mold Making Process

- Design & DFM Analysis: CAD modeling and manufacturability review.

- Mold Flow Analysis: Simulates plastic flow to optimize gate location and cooling.

- Material Selection: Based on part requirements and mold longevity.

- Machining: CNC and EDM processes shape the mold.

- Assembly: Components are assembled into a working mold.

- Trial & Tuning: Test shots ensure the mold produces accurate parts.

- Validation & Delivery: Final inspection and shipping.Injection Mold Making Process Injection Mold Making Process

Molds Material Selection Guide

Choosing the right material for the mold is key to performance and cost-effectiveness:

- P20 Steel: Pre-hardened, suitable for medium production.

- 718 Steel: Excellent polishability, used for clear parts.

- NAK80: Pre-hardened, good for cosmetic finishes.

- H13 Steel: High wear resistance, ideal for high-volume runs.

- S136 Stainless Steel: Corrosion-resistant, for medical/optical applications.

- Aluminum: Quick machining, good for prototyping or low volume.

- Beryllium-Copper: Used for inserts requiring rapid heat transfer.

Design Considerations for Injection Molds

Mold design plays a crucial role in the efficiency of the injection molding process. Some important design considerations include:

- Part Geometry: The complexity of the part geometry directly influences the design of the mold. Sharp corners, deep cavities, or intricate shapes may require special modifications in the mold structure.

- Draft Angles: Draft angles are sloped surfaces that facilitate the removal of the part from the mold. The inclusion of these angles ensures that parts are ejected smoothly and without damage.

- Wall Thickness: Consistent wall thickness ensures uniform material flow and helps avoid defects such as sink marks and warping.

Factors Affecting Plastic Injection Mold Making Cost

Mold cost varies widely depending on:

- Part Complexity: More intricate parts require more complex tooling.

- Number of Cavities: Multi-cavity molds are more expensive but increase output.

- Mold Size & Material: Larger molds and premium materials cost more.

- Precision & Tolerance: Tight tolerances increase machining cost.

- Surface Finish Requirements: High polish or texture adds to cost.

- Cooling & Cycle Time Design: Efficient cooling improves productivity but may add complexity.

Tips to Reduce Mold Cost:

- Simplify part design

- Use standardized mold bases

- Optimize gate and cooling layout early

Mold Quality Control and Testing

Ensuring the mold performs correctly involves rigorous quality procedures:

- Material Inspection: Verify hardness and specifications.

- Dimensional Checks: CMM machines and 3D scanning verify accuracy.

- Trial Molding: Evaluate molded samples for flash, warping, or short shots.

- Final Mold Qualification: Includes production-ready testing and documentation.

Importance of Mold Maintenance and Care

Proper mold repair and maintenance are essential for maintaining consistent part quality and ensuring long-term efficiency. Regular cleaning, lubrication, and inspection can prevent mold wear, and repairs should be made promptly to avoid delays in production.

Why Choose Jiangzhi Injection Mold Making Services?

Since 1978, we’ve specialized in mold design and manufacturing with decades of experience and state-of-the-art facilities. We offer:

- One-stop solutions: From design to finished mold

- Advanced software & equipment: CAD/CAM, mold flow analysis, precision CNCs

- Material flexibility: Support for a wide range of mold steels and inserts

- Strict quality control: ISO standards, full documentation

- Fast lead times: Streamlined project management for on-time delivery

Conclusion

Injection mold making is far more than a technical procedure—it’s the foundation of reliable, scalable, and cost-effective plastic part production. Drawing on decades of manufacturing experience, we know that every detail matters: from precise mold design and material selection to rigorous testing and maintenance. At Jiangzhi, we are committed to delivering injection molds that meet the highest standards of durability, precision, and performance. Partnering with an experienced mold maker ensures that your product not only meets today’s requirements but is also built for long-term success. Ready to turn your ideas into high-quality parts? Our team is here to help you every step of the way.