Injection molding voids are one of the key challenges that can impact both the functionality and aesthetics of plastic parts. Understanding what causes these voids, identifying their types, and implementing strategies to prevent them is crucial for achieving high-quality products.

What is an Injection Molding Void?

An injection molding void is an internal cavity or space that forms within a molded plastic part during the injection molding process. These voids in injection molding arise primarily from uneven cooling, material shrinkage, or trapped gases, creating pockets that disrupt the uniformity of the material. Injection molding voids are often internal and may not be visible from the outside, yet they can weaken the part’s mechanical integrity.

Common Types of Voids in Injection Molding

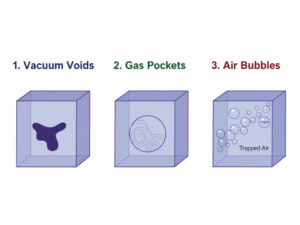

There are several types of voids to be aware of when discussing voids in injection molding:

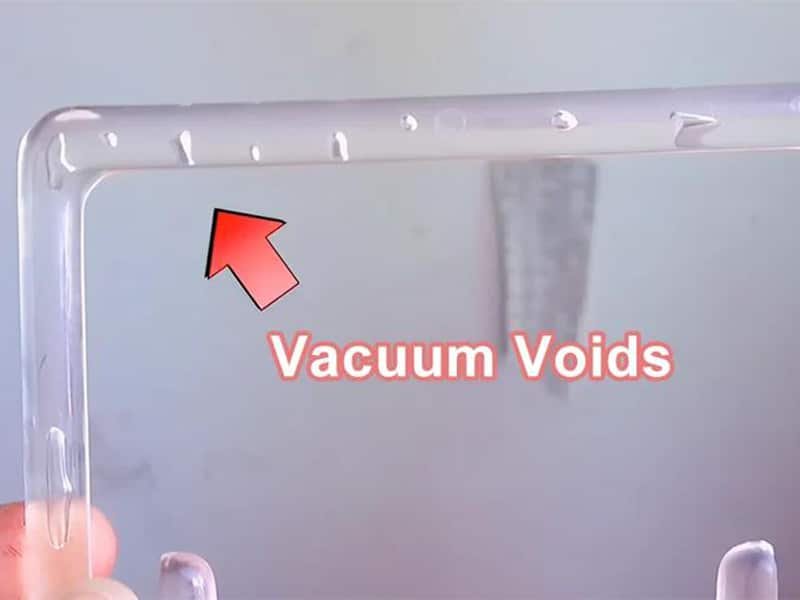

Vacuum Voids: These occur when the plastic material contracts during cooling, creating a low-pressure area that pulls in surrounding material unevenly. Vacuum voids injection molding is especially common in thicker sections of a part, where the outer layers solidify first, leaving the inner core to shrink and form hollow spaces. This type doesn’t involve actual gas but results from differential shrinkage rates.

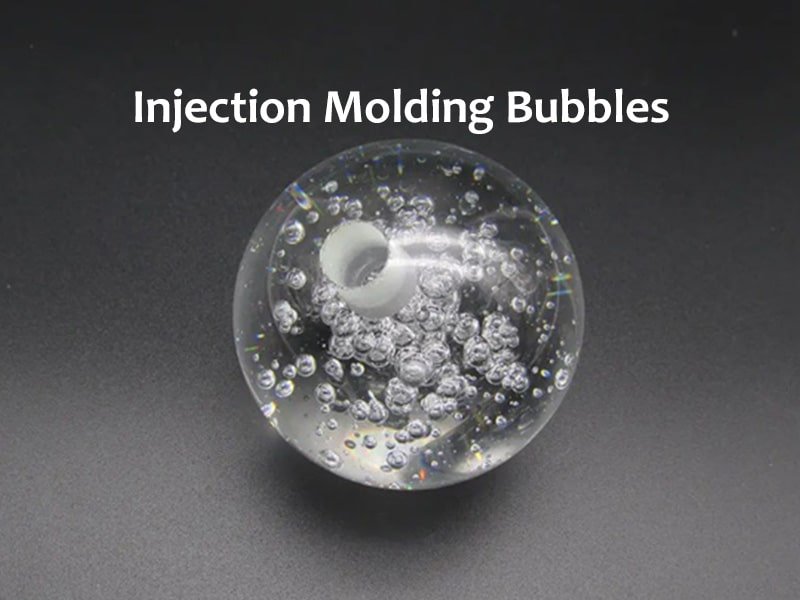

Gas Pockets: Unlike vacuum voids, gas pockets form due to trapped air or volatile gases released from the molten plastic. During injection, if gases aren’t properly vented, they accumulate, creating bubble-like enclosures. These can lead to discoloration or splay marks on the surface, exacerbating aesthetic problems alongside structural ones.

Air Bubbles: Similar to gas pockets but often smaller. They are stemming from moisture in the resin, and air bubbles arise when water vaporizes at high temperatures, expanding into voids. In hygroscopic materials like nylon, inadequate drying can amplify this issue, resulting in scattered bubbles that weaken the part’s density.

Sink Marks: While not strictly a void, sink marks frequently accompany injection molding voids as an external symptom. They appear as depressions on the surface where internal shrinkage, often from vacuum voids, pulls the outer skin inward. Think of sink marks as the visible warning sign of deeper voids in plastic parts, signaling issues like insufficient packing pressure or uneven wall thickness.

Causes of Injection Molding Voids

The formation of voids injection molding is influenced by several factors:

Design Factors

Uneven wall thicknesses lead to differential cooling rates. Thicker areas cool more slowly, promoting shrinkage and vacuum voids in injection molding. Poor gate placement can exacerbate this, as it may cause uneven flow, trapping air, and forming gas pockets. Sharp corners or inadequate ribbing further complicate matters, creating stress points where voids in plastic parts are likely to form.

Process Parameters

Insufficient injection pressure fails to pack the mold fully, allowing material to shrink away and create injection molding voids. High melt temperatures can volatilize additives, generating gas bubbles, while rapid injection speeds induce turbulence, entrapping air. Uneven mold cooling causes differential shrinkage and stresses, which can trigger internal void creation or surface sink marks. Back pressure during plastication, if inadequate, doesn’t homogenize the melt properly, leading to inconsistencies that manifest as defects.

Materials Properties Factors

Hygroscopic resins absorb moisture from the air, which turns to steam during molding and forms air bubbles or gas pockets. High-viscosity materials resist flow, increasing the risk of incomplete filling and subsequent voids injection molding. Even non-hygroscopic polymers can suffer if contaminated with volatiles, heightening the vacuum voids injection molding risks.

Mold Related Factors

Inadequate venting channels trap gases, directly causing gas pockets and air bubbles. Uneven mold temperatures, perhaps from clogged cooling lines, promote localized shrinkage and sink marks. Gate and runner sizes that are too small restrict flow, amplifying pressure drops and voids in plastic parts. Wear and tear on the mold over time can introduce flash or misalignment, indirectly contributing to defects.

How to Avoid Injection Molding Voids?

Avoiding voids in injection molding requires a holistic approach, optimizing each stage from design to production.

Design Optimization

Maintain uniform wall thicknesses to ensure even cooling and minimize vacuum voids injection molding. Strategically place gates near thick sections for better packing, and incorporate generous radii to reduce stress concentrations. Use simulation software early to predict flow patterns and identify potential voids in plastic parts before tooling begins.

Process Parameters Control

Increase packing pressure and hold time to compensate for shrinkage, effectively filling incipient voids. Lower melt and mold temperatures to reduce gas evolution, but balance this to avoid short shots. Slow down injection speeds for smoother flow, reducing turbulence and air entrapment. Extend cooling times and monitor cycle consistency with sensors.

Handling Material Correctly

Dry resins thoroughly to eliminate moisture-induced air bubbles. Use polymers known for minimal shrinkage to reduce void susceptibility, especially for thick parts. Select materials with excellent flow characteristics to fill complex mold features.

Adjust Mold Design

Add or enlarge vents for efficient gas escape. Optimize cooling circuits for uniform temperature distribution, preventing localized shrinkage and sink marks. Consider hot runner systems for better control over melt delivery, reducing voids in the injection molding of complex parts. Routine inspections and polishing keep tools in top shape.

Conclusion

Modern simulation tools like CAE can predict and prevent these defects, enhancing efficiency. Jiangzhi is an experienced injection molding supplier with decades of experience and delivers tailored, void-free solutions. Welcome to partner with Jiangzhi to achieve your high-quality parts.