Unlike traditional injection molding, which is optimized for mass production of thousands or millions of parts, low-volume injection molding focuses on producing small batches efficiently, cost-effectively, and with high quality. This guide explains the process, advantages, design considerations, and mold manufacturing for low-volume injection molding.

What is Low Volume Injection Moulding?

Low-volume injection molding is a process for producing plastic parts in quantities typically under 10,000 units, making it ideal for prototyping, pilot runs, or specialized applications. The process works like traditional injection molding: molten thermoplastic is injected into a mold cavity, where it cools and solidifies into the desired shape.

Unlike large-scale production, low-volume molding uses cost-effective molds—often made from aluminum or 3D-printed resins instead of hardened steel. These molds are faster and cheaper to produce, sometimes ready in just a few days, which reduces setup time and overall production costs.

Another advantage of low-volume injection molding is its flexibility. It can produce complex shapes that may be difficult or uneconomical with traditional large-scale methods. This makes it a practical solution for early-stage product development, testing, and small-batch manufacturing.

Key Difference from Large-Scale Production:

| Feature | Low-Volume Molding | Large-Scale Molding |

|---|---|---|

| Mold Material | Aluminum or 3D-printed resins | Hardened steel |

| Lead Time | Days | Weeks to months |

| Production Flexibility | High | Low |

| Cost | Low upfront | High upfront |

The Low Volume Injection Molding Process

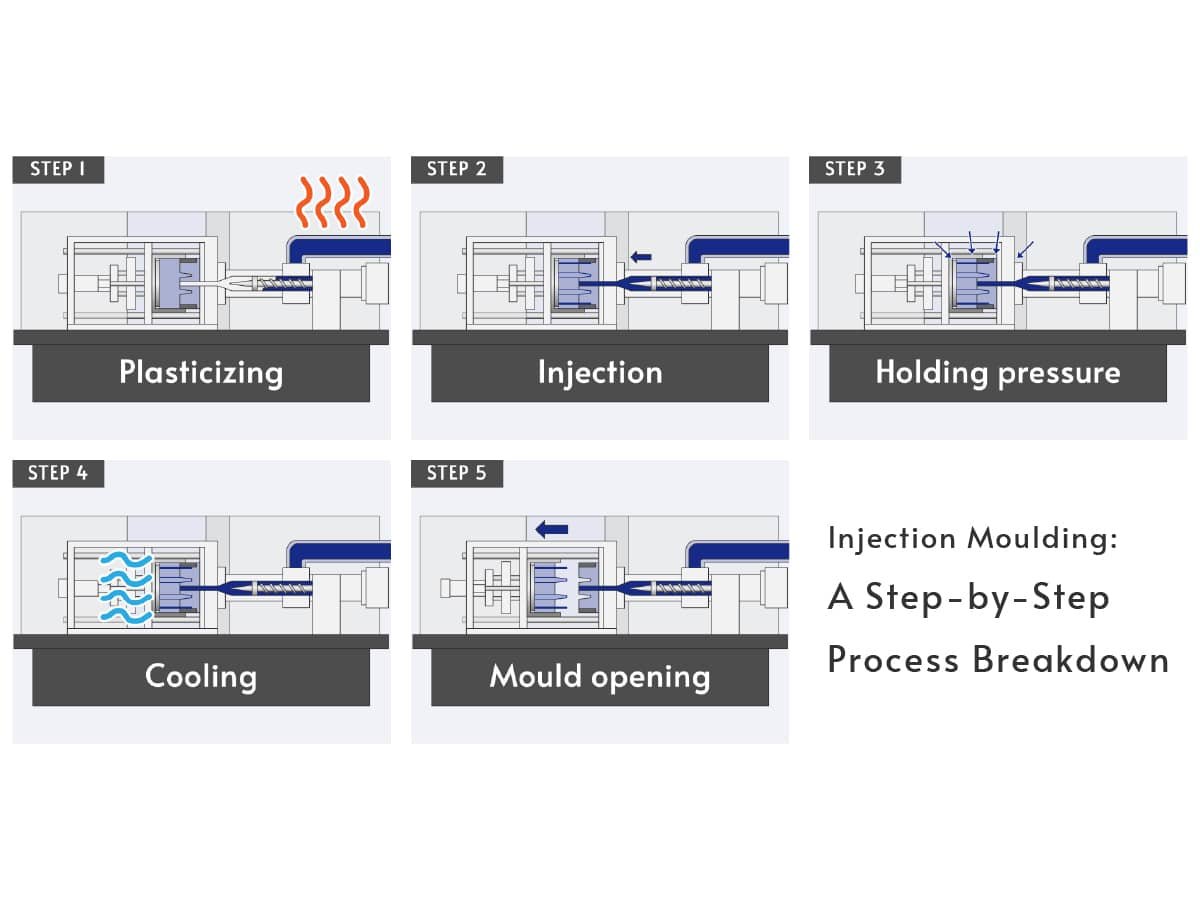

The low-volume injection moulding process is a streamlined sequence designed for efficiency and precision, tailored to smaller production runs. Here’s how it works:

- Mold Design and Fabrication: Engineers create a mold using CAD software, optimizing it for the desired part geometry. Once designed, the mold is fabricated—commonly through CNC machining or electrical discharge machining (EDM). Aluminum molds are faster and cheaper to produce than steel, making them optimal for short runs.

- Clamping: The mold halves are clamped together under high pressure to ensure a tight seal during injection, preventing leaks or defects.

- Injection: Molten plastic, such as ABS, polycarbonate, or nylon, is injected into the mold cavity at high pressure, filling every detail of the mold.

- Cooling: Coolant circulates through channels in the mold, rapidly solidifying the plastic to maintain dimensional accuracy and prevent warping.

- Ejection: Once cooled, the mold opens, and ejector pins release the finished part, ready for inspection or post-processing.

- Quality Control: Parts undergo rigorous checks, often using Statistical Process Control (SPC), to detect issues like sink marks, warping, or incomplete fills.

When to Use Low-Volume Injection Molding?

Low-volume injection molding is ideal when flexibility, speed, and cost-efficiency outweigh the need for mass production. Here are the key scenarios where it delivers the most value:

- Prototyping & Design Verification: Perfect for functional prototypes or pilot runs when designs are ready for real-world testing before full-scale production.

- Market Testing & Early-Stage Products: Small batches reduce risk when introducing new products and allow for quick consumer feedback.

- Small-Batch Manufacturing: Suitable for startups, specialty products, or limited runs of 100–10,000 parts, offering lower upfront investment and faster lead times.

- Frequent Design Changes: Easy tooling modifications make it ideal for products that evolve rapidly or require version updates.

- Customization & On-Demand Production: Supports multiple colors, variants, or niche products without large inventory or tooling costs.

- Budget Constraints & Volume Uncertainty: Reduces financial risk when future demand is hard to predict.

Design Guidelines for Low-Volume Injection Molding

Good part design is essential. Follow Design for Manufacturability (DFM) principles:

- Wall Thickness: Keep uniform (1–3.5 mm) to prevent warping.

- Draft Angles: 1–2° for easy ejection.

- Ribs & Gussets: Ribs ~½ wall thickness; gussets only where needed.

- Corners: Replace sharp corners with fillets to reduce stress.

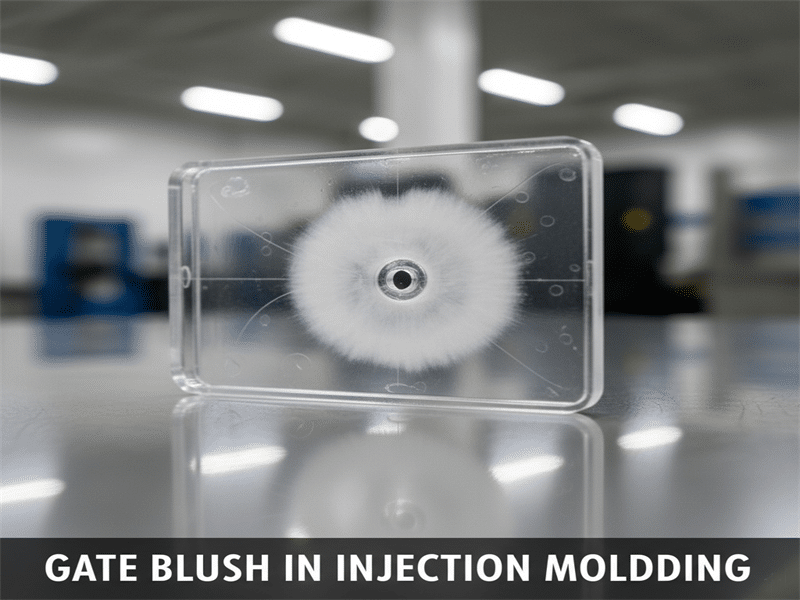

- Gate Locations: Plan for even filling and minimal marks.

- Ejector Pins & Parting Lines: Consider during design to ensure smooth mold release.

These guidelines help avoid production issues while optimizing cost and quality.

Mold Manufacturing for Low-Volume Injection Molding

In low-volume injection molding, mold manufacturing is designed for speed, cost-efficiency, and flexibility:

- Mold Type: MUD (Master Unit Die) or simple aluminum molds are commonly used. They are quick to produce and cost-effective for small batches.

- Mold Material: Aluminum is preferred for low-volume production because it is easy to machine and fast to produce. Steel is rarely needed unless very high precision or durability is required.

- Manufacturing Methods: CNC machining is the standard for small molds. EDM is used only for intricate features or mirror finishes.

- Finish & Temperature Control: Aluminum molds allow fast production and adequate surface quality. Proper temperature control prevents warping or defects.

Why it works for small batches: These choices minimize lead time and cost while ensuring quality, making small-volume production practical and efficient.

Partner Jiangzhi as a Volume Injection Moulding Manufacturer

Jiangzhi offers advanced manufacturing technologies, flexible production, expert design support, and competitive pricing, enabling rapid mold production and high-precision parts. Get in touch today to explore a custom low-volume injection molding solution for your project!