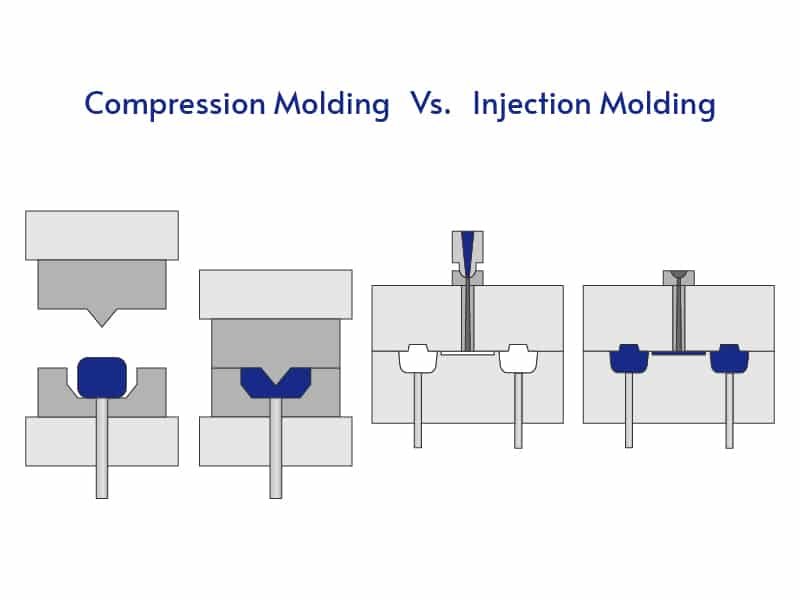

PTFE compression molding is one of the most effective methods for manufacturing precise, durable PTFE components. Polytetrafluoroethylene (PTFE), also known as Teflon, is a fluoropolymer with chemical resistance, thermal stability up to 260 °C, low friction, non-stick behavior, and electrical insulation, making it suitable for demanding applications in harsh environments. Its extremely high melt viscosity prevents it from flowing during standard processing methods like injection molding, but compression molding service overcomes this limitation, enabling the production of complex, high-performance PTFE parts.

Why PTFE Is Ideal for Compression Molding?

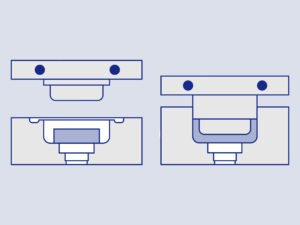

PTFE is uniquely suited for compression molding because of its exceptionally high melt viscosity and non-melt-processable molecular structure. Unlike most thermoplastics, PTFE cannot be shaped through conventional injection molding. Instead, it is processed in powder form and compacted under high pressure to achieve the desired shape, then sintered to fuse the particles.

This method is ideal because it maintains PTFE’s chemical inertness, thermal stability, and dimensional precision. During sintering, the material does not flow like typical plastics; the particles bond together while preserving the low friction, high wear resistance, and other performance properties that PTFE is known for.

PTFE Compression Molding Process: Step-by-step

The PTFE compression molding process follows a sequence of stages to convert powder into finished parts.

- Material Preparation: Select PTFE powder based on application needs. Blend components thoroughly to ensure uniformity. Dry the powder if necessary to remove moisture, which could cause defects.

- Filling the Mold: The conditioned PTFE powder is placed in a pre-shaped mold cavity that defines the final part’s geometry.

- Compaction: Hydraulic presses exert pressures on the powder. This high pressure compacts the powder tightly, reducing voids and increasing density.

- Sintering: The molded preform is then heated to just above the polymer’s melting point. This elevated temperature causes the PTFE particles to fuse into a solid, uniform structure while maintaining the material’s key properties.

- Cooling: Controlled cooling of the part slowly to room temperature to control crystallization and avoid warping.

- Finishing: Inspect for density and dimensions. Apply hot coining for surface smoothness or machine for precise tolerances if required.

Advantages of PTFE Compression Molding

The benefits of compression molding PTFE are numerous and directly linked to the polymer’s characteristics and the precision of the process. Key advantages include:

- Dimensional Accuracy and Uniformity: The process yields parts with tightly controlled tolerances, and the process compacts powder evenly, resulting in consistent density and strength throughout the part.

- Capability for Complex and Large Components: Unlike other methods limited by melt flow, compression molding PTFE can produce intricate parts with variable thicknesses and large sizes without sacrificing quality.

- Minimal Material Waste: Powder fills the mold directly, and material loss is significantly reduced compared to machining or other subtractive methods.

- Cost-Effectiveness for Low Volumes: Tooling is less complex than for injection molding, making it suitable for prototypes or small runs. Cycle times, while longer, allow flexibility without high setup expenses.

- Retention of Superior Material Properties: Compression molding preserves PTFE’s outstanding chemical resistance, thermal stability, and low friction, critical for demanding environments.

- Versatility with Fillers: Additives like carbon or bronze integrate easily during powder preparation, tailoring properties such as thermal conductivity or lubricity.

Design Guidelines for Successful PTFE Compression Molding

Achieving the best results with compression molding PTFE begins with thoughtful design, addressing the polymer and process limitations:

Geometry and Tolerances

Maintain uniform wall thicknesses to promote even compaction. Use draft angles and radii at corners to facilitate demolding and reduce stress points.

Mold Features

Incorporate venting to prevent porosity from gas buildup. Pre-heat inserts to match thermal expansion and surround them with at least 2 mm of PTFE to avoid gaps.

Allowance for Shrinkage

Consider the characteristic shrinkage of PTFE during cooling and sintering to maintain accurate final dimensions.

Testing and Iteration

Prototype under end-use conditions, including chemical exposure and temperature cycles. Use simulation software to predict shrinkage and warpage.

Typical Applications of PTFE Compression Molded Parts

PTFE compression-molded components serve crucial roles across different industries:

- Aerospace: Bushings for actuators, seals in engines, bearings in landing gear.

- Medical: Implants for joint replacements, gaskets, and tubing.

- Chemical Processing: Liners, valves, dip pipes.

- Electrical: Insulators, sheaths, connectors.

- Automotive: O-rings, guides, piston rings.

Conclusion

PTFE compression molding provides a reliable method for producing high-performance PTFE parts. When selecting a PTFE compression molding supplier, prioritize those with proven expertise in fluoropolymers and quality controls like density testing. Jiangzhi offers PTFE compression molding services, along with PTFE injection molding and CNC machining for precision components. You are welcome to contact Jiangzhi to obtain a custom molding solution tailored to your specific needs.