In the plastics manufacturing industry, two processes dominate the production of hollow and semi-hollow parts: rotational molding (also called rotomolding or rotational moulding) and injection molding (injection moulding). Both methods produce high-quality plastic components, but they differ significantly in design capabilities, tooling costs, production volumes, and end-product characteristics.

What Is Rotational Molding?

Rotational molding is a low-pressure process used to produce large, hollow, seamless parts. A measured amount of plastic powder is placed inside a metal mold. The mold is closed, heated, and rotated on two perpendicular axes. As the plastic melts, it spreads evenly across the inner surface. The mold keeps rotating during cooling to maintain a consistent wall thickness. Once the part solidifies, it is removed. With no injection pressure involved, the finished parts have very low internal stress and strong structural stability.

What Is Injection Molding?

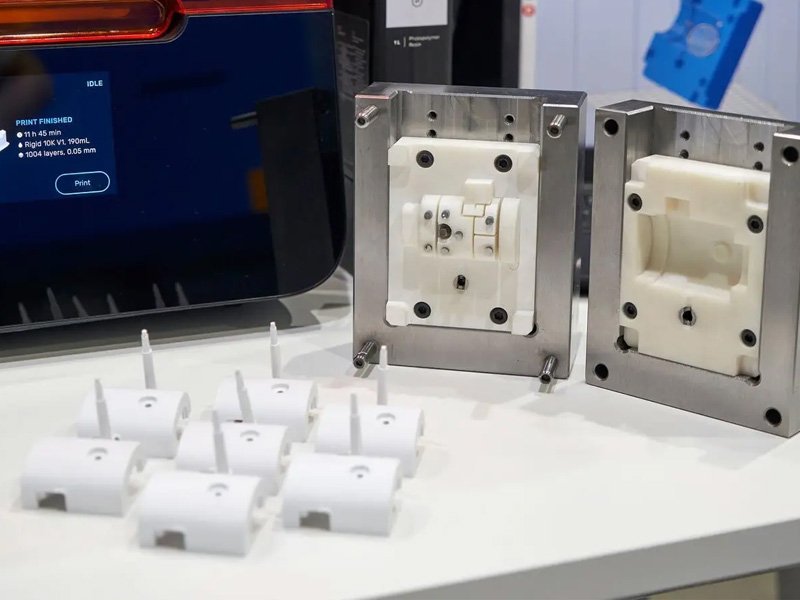

Injection molding is a high-pressure process. Plastic pellets are fed into a heated barrel, melted, and then injected under high pressure into a closed steel mold. The molten plastic fills the mold cavity completely within seconds. The mold is cooled with water channels, the part solidifies, and ejector pins push it out. Plastic injection molding is widely used for producing parts with complex geometries, tight tolerances, and consistent surface finishes.

Key Differences Between Rotational Molding and Injection Molding

When comparing rotational molding vs injection molding, several factors influence the choice between the two processes, including design complexity, mold requirements, material compatibility, production speed, and cost.

Design Complexity & Size

Rotational molding is suitable for large, hollow, double-wall, or seamless parts. Wall thickness is naturally uniform. Undercuts and varying thicknesses are easy to achieve. Part size can exceed 3 meters.

The injection molding process is best for precise, thin-walled, or highly detailed parts. Large parts become expensive because multiple components must be assembled. The maximum practical size is usually under 1.5 meters.

Mold Considerations

Injection molding requires high-precision, hardened steel molds, which are expensive to fabricate. Modifications are costly and sometimes impossible without new tooling. However, it offers long-term durability for high-volume production.

Rotational molding molds are typically made of aluminum or steel, have lower upfront costs, and are simpler in design. However, they have limited longevity compared to injection molds and require careful maintenance to ensure uniform part quality.

Material

Injection molding supports a wide range of materials, from standard thermoplastics to engineering-grade polymers. This flexibility enables manufacturers to optimize mechanical properties, color, and surface finish.

Rotational molding is generally limited to lower-density thermoplastics, such as polyethylene, though advances in material science are expanding options.

Production Speed and Volume

Injection molding is highly efficient for mass production, with cycle times measured in seconds to minutes per part.

Rotational molding is slower, often taking 20–60 minutes per cycle, depending on part size, making it more suitable for smaller production runs.

Cost Considerations

Initial mold cost is significantly higher for injection molding, but it becomes cost-effective at high production volumes due to low per-part cost.

Rotational molding has lower initial mold expenses but higher labor and cycle-time costs, resulting in higher per-unit costs for large production runs.

Advantages of Rotational Molding

Rotational molding offers several distinct benefits, particularly for specific product types:

- Uniform wall thickness: Ideal for large hollow structures that require consistent strength and durability.

- Lower mold cost: Initial tooling expenses are significantly less than injection molding, making it attractive for prototypes and small production runs.

- Durable and impact-resistant parts: The process produces stress-free parts with fewer internal weaknesses.

- Ability to produce large items: Tanks, kayaks, furniture, and storage containers can be manufactured more easily than with injection molding.

- Simplified design modifications: Adjustments to mold design are easier and more cost-effective compared to high-precision injection molds.

Advantages of Injection Molding

Injection molding provides distinct advantages that make it the process of choice for high-volume, precision parts:

- High production speed: Parts are produced quickly with minimal labor per unit.

- Complex geometries and tight tolerances: Features such as threads, snap-fits, and intricate surface details can be accurately produced.

- Wide material selection: Thermoplastics, thermosets, and high-performance polymers can be utilized, allowing for customized mechanical and aesthetic properties.

- Repeatable quality: Each part meets strict dimensional specifications, essential for assembly line production.

- Lower per-unit cost at scale: High initial mold costs are offset by efficiency in large-volume production.

How to Choose Between Rotational Molding and Injection Molding?

Let’s take a storage container as an example. When manufacturing a plastic storage container, the choice between rotational molding vs injection molding depends on design complexity, size, and production volume.

If the container has a simple design, requires a large size, and the production quantity is relatively low, rotational molding is a suitable option. This process allows for uniform wall thickness, strong structural integrity, and lower initial mold costs, making it practical for large hollow containers without intricate details. The flexibility in mold design also enables adjustments such as thicker bases or rounded edges without significantly increasing costs.

If the storage container includes precise design features, such as snap-on lids, textured surfaces, or internal compartments, injection molding is the more appropriate choice. Although the molds require higher upfront investment, injection molding ensures high precision, consistent dimensions, and fine surface details, making it ideal for medium to high-volume production.

Conclusion

Choosing the right manufacturing process depends on the specific requirements of the product, including size, complexity, material, and production volume. For professional guidance and reliable production, Jiangzhi offers expert injection molding services to meet a wide range of project needs.

Your One-Stop Manufacturing Partner

FAQ

Both use thermoplastics, heat plastic to a molten state, shape it in molds, require cooling to solidify, suit high-volume production, and produce durable plastic parts.

Blow molding is the preferred method because it efficiently forms hollow containers with thin, uniform walls.