Rubber flash is a common rubber part defect during the manufacturing of molded rubber parts. It is often dismissed as a minor defect. In this article, we will explore what rubber flash is, the causes, and effective prevention methods.

What Is Rubber Flash?

Rubber flash, sometimes called flashing, is the thin layer or excess rubber that extends beyond the intended geometry of a molded part. It forms when molten rubber material leaks between the mating surfaces of a mold during the curing or vulcanization process. The presence of flash indicates that the mold is not perfectly sealed, allowing rubber material to escape under pressure and solidify where it is not desired. Flash can vary from barely visible fine lines to large excess edges that require manual trimming or mechanical deflashing post-production.

The process of removing such rubber flash is known as deflashing. Common removal methods include manual trimming, mechanical cutting, cryogenic deflashing, and abrasive blasting. Each method comes with its own advantages, limitations, and suitable applications depending on the part’s size, complexity, production volume, and quality requirements.

Causes of Rubber Flash in Injection Molding

Understanding what causes rubber flash is the first step in minimizing or eliminating it during manufacturing. The main causes include:

Mold Parting Line Gaps

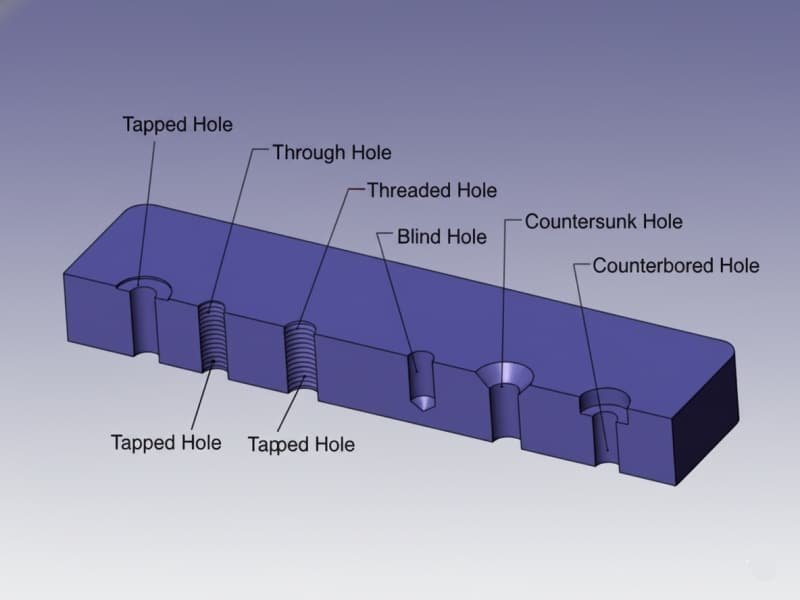

The mold’s parting line is where the two halves of the mold meet and seal to form the cavity. Even minute gaps can allow rubber to leak through. These gaps can arise due to imprecise mold fabrication, wear and tear over time, or contamination such as dust and debris, preventing proper mold closure. The tighter and more precise the mold’s mating surfaces, the less flash is produced.

Insufficient Clamping Pressure

During molding, the mold halves must be tightly clamped together to resist the pressure of injected or compressed rubber. If the clamping force is inadequate, the mold may slightly open under pressure, causing rubber material to escape at the parting line.

Excessive Rubber Material or Overfilling

Overfilling the mold cavity by adding more rubber than its designed volume causes overflow. This excess material pushes against the mold edges, leading to flash.

Rubber Compound Fluidity and Vulcanization Rate

The physical characteristics of the rubber compound, including viscosity and cure speed, influence flash formation. Highly fluid compounds can seep into mold gaps more easily, while vulcanization speed affects how quickly the rubber solidifies, impacting the chance of flash forming during mold filling and packing.

Mold Design and Maintenance Issues

Complex part geometries with fine features or multiple cores can create challenging molds prone to flash. Additionally, worn or damaged mold components, such as seals, ejector pins, and cavities, can deteriorate sealing integrity.

Incorrect Molding Parameters

Molding parameters—temperature, pressure, and curing time—must be finely tuned, or rubber flash becomes inevitable. Excessive injection pressure drives rubber through the smallest crevices, while high temperatures reduce viscosity, making the material more prone to overflow. Conversely, short curing times might leave the rubber semi-molten, allowing it to shift and form flash rubber during demolding.

How to Avoid Rubber Flash in Injection Molding?

Avoiding rubber flash demands a multifaceted strategy, combining design with operational. Here are key techniques to implement:

- Optimize Mold Design: Prioritize precise parting lines, adequate venting, and overflow grooves to channel excess rubber. Use CAD simulations to predict flow patterns and refine geometries before fabrication.

- Regular Mold Maintenance: Routine inspection and cleaning of mold surfaces removes debris and contaminants that disrupt sealing. Addressing wear or damage promptly through repair or polishing helps maintain consistent mold integrity, minimizing flash creation over time.

- Adjust Clamping Force: Calibrate presses to deliver sufficient force tailored to the mold and material, ensuring the mold halves stay securely closed during the entire injection or compression cycle.

- Proper Material Dosing and Molding Parameters: Accurate dosing to prevent overfilling of cavities, combined with optimized injection speed and pressure, prevents excessive material flow.

- Select Appropriate Materials: Choose rubber compounds with optimal viscosity and thermal stability. Test batches for uniformity to prevent surprises that lead to rubber flash.

- Adopt Advanced Techniques: Using mold flow simulation software detects potential flash-prone zones in mold design, allowing proactive adjustment.

Conclusion

Rubber flash is an inevitable challenge in molded rubber part production, but it can be effectively minimized and managed with the right knowledge and techniques. Leveraging advanced production technology and extensive expertise, Jiangzhi delivers high-quality rubber products while addressing not only rubber flash but also other common compression molding defects to ensure consistent performance and reliability.