Thermoset materials, such as epoxies, phenolics, and rubbers, undergo irreversible curing during processing. Compression molding and transfer molding serve as two common methods for forming parts from these materials. Both techniques apply heat and pressure to achieve cross-linking and the final shape. Each method brings distinct advantages, process characteristics, and cost profiles. The choice between transfer molding vs compression molding depends on factors like part complexity, production volume, and cost requirements. This article examines each process in detail, highlights key differences, and provides guidance on selection.

What is Compression Molding?

Compression moulding is a manufacturing process used primarily for forming elastomers, thermosetting plastics, and high-durometer rubber materials. In this method, a pre-measured amount of uncured material is placed directly into the mold cavity. The mold is then closed, and both heat and pressure are applied to shape and cure the material. As the rubber or resin flows to fill the cavity, any excess material is directed into overflow grooves to ensure uniform part formation. Once curing is complete, the mold is opened and the part is demolded, followed by trimming to remove any flashing.

This molding process is suitable for materials that are difficult to flow. Compression molding is well-suited for large, thick-walled components and expensive materials. Because compression molding can minimize waste during manufacturing. Compression molding offers strong material integrity, excellent mechanical performance, and cost efficiency for specialized rubber and silicone components.

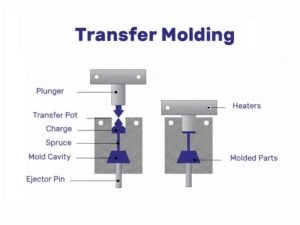

What is Transfer Molding?

Transfer molding is a molding process that combines aspects of both compression and injection molding. In this method, a pre-measured amount of uncured rubber or thermoset material is placed into a chamber known as the “pot,” which is an integral part of the mold assembly. When the mold is closed, a plunger applies pressure, forcing the heated material through sprues and runners into the individual cavities. The mold remains sealed as the material cures under controlled temperature and pressure. After curing, the mold is opened and the parts are removed for trimming, where excess material, known as flash, is eliminated to achieve the final product shape.

This process offers excellent dimensional accuracy and consistency, making it suitable for producing complex and precision-engineered components. Transfer molding allows multiple cavities to be filled simultaneously from a single preform, improving production efficiency. Transfer molding is widely used in the medical, automotive, and electronics industries to create products such as seals, gaskets, diaphragms, valve seats, and electrical insulators.

Main Differences Between Compression and Transfer Molding

Compression molding vs transfer molding: which manufacturing method is suitable for your project? Here is a comparison table to show the differences in the different aspects.

| Aspect | Compression Molding | Transfer Molding |

|---|---|---|

| Fill Approach | Compression molding fills directly into an open cavity | Transfer molding uses a transfer chamber to preheat and then inject into a closed cavity. |

| Dimensional Tolerance and Geometry | Compression molding is typically simpler with moderate tolerances. | Transfer molding generally achieves higher tolerances and can reproduce more complex features |

| Mold Structure | Open cavity in two-plate mold; no gates or runners. | Closed cavity with separate pot, plunger, runners, and gates; often three-plate. |

| Mold Materials | P20 or NAK80 steel; hardness 45–50 HRC; basic polishing sufficient. | H13 or SKD61 hot-work steel; hardness 50–55 HRC; PVD or CrN coatings for wear resistance and release. |

| Equipment Needs | Vertical hydraulic press (50–500 tons) with heated platens; manual or semi-auto loading. | Dedicated transfer press with plunger cylinder; precise pressure control ±0.5 MPa; fast clamping under 3 seconds. |

| Material Flow | Short radial flow from charge; risk of air pockets in deep sections. | High-pressure injection through gates; shear thinning improves fill; better venting. |

| Cycle Time | 2–6 minutes, dominated by manual charge placement. | 1–3 minutes, with higher automation. |

| Waste Rate | Under 1%, limited to flash. | 5–15%, from sprue and runners (recyclable). |

| Typical Wall Thickness | ≥3 mm. | 0.5–3 mm. |

| Insert Handling | Manual placement; potential shift during flow. | Pre-fixed in cavity; high positional accuracy. |

| Part Cost Factors | Low mold cost; higher labor. | High mold cost; lower labor in volume. |

| Typical applications | Compression molding suits large, simple geometries and high-volume parts. | Transfer molding targets complex shapes, tight tolerances, and multi-cavity feeding scenarios. |

How to Quickly Choose Compression VS Transfer Molding?

In the debate of transfer molding vs compression molding, compression suits flat, thick parts in low volumes with budget constraints. Transfer excels in detailed, insert-laden parts at higher volumes needing precision. Choose compression for material efficiency and simple setups; opt for transfer when uniformity and thin sections dominate. Hybrid approaches start with compression for prototypes, shifting to transfer for production.

Conclusion

The preferred partner should not only provide custom parts manufacturing but also supply from design optimization to scalable production. Jiangzhi offers capabilities in both rubber compression and rubber injection molding, providing DFM reviews and custom solutions. Welcome to contact us for your new project.