Custom Machined Nylon Parts

Jiangzhi specializes in PA CNC machining, delivering high-precision CNC machined nylon parts from prototype to production — with fast turnaround and competitive pricing.

Nylon CNC Machining Services

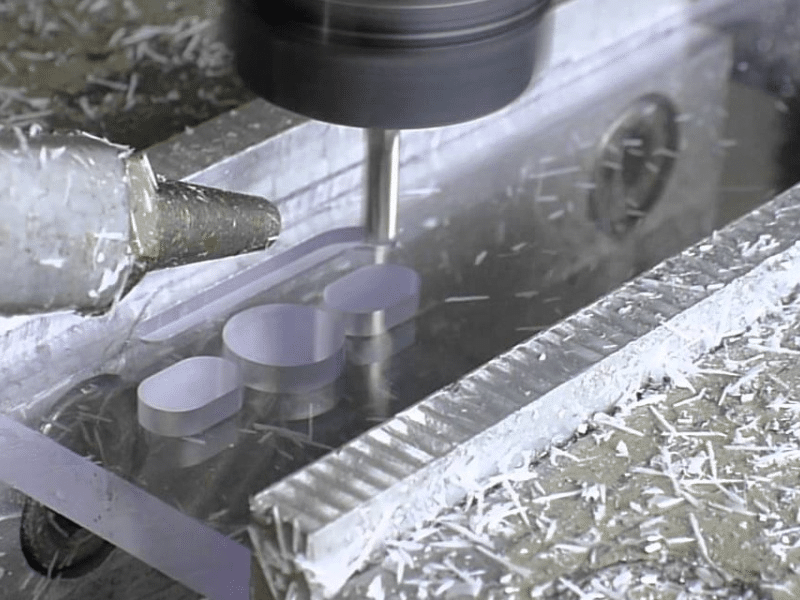

CNC machining of nylon involves the use of computer-controlled tools to remove excess material and precisely perform operations such as cutting, turning, or milling. This process produces strong, lightweight, and wear-resistant nylon parts with excellent dimensional accuracy. In some applications, nylon can even replace metal, offering lower maintenance and improved wear performance.

At Jiangzhi, we offer high-quality, custom CNC nylon machining solutions tailored to your specifications. Backed by advanced equipment and a team of experienced engineers, we support a variety of machining and secondary processing techniques. With cost-effective nylon grades such as PA6 and PA66, we ensure precision, fast delivery, and competitive pricing. Equipped with 3-axis, 4-axis, and 5-axis milling and turning centers, we can manufacture CNC custom nylon parts that meet your exact requirements.

| Price | $$$ |

|---|---|

| Process | CNC Turning, CNC Milling |

| Tolerances | ±0.02 mm |

| Maximum Part Size | 4000 mm × 1500 mm × 600 mm |

| Minimum Feature Size | Φ 0.8 mm |

| Wall Thickness | 1 mm |

| Lead Time | About 3-6 days |

Nylon CNC Machining Materials

Nylon is a versatile synthetic thermoplastic polymer widely used in engineering and manufacturing. It offers a strong combination of mechanical strength, toughness, and resistance to heat, abrasion, and chemicals. Available in a range of grades with varying properties, nylon can be processed through different methods, making it suitable for both injection molding and CNC machining applications.

- Nylon 6/6 (PA 66) – Known for its high strength and wear resistance, it's commonly used in gears, bushings, and other mechanical parts.

- Nylon 6 (PA 6) – Offers good toughness and impact resistance, often found in automotive components and electrical insulation.

- Nylon 12 (PA 12) – Low moisture absorption gives it excellent dimensional stability, making it ideal for fuel lines and pneumatic tubing.

- Glass-Filled Nylon – Reinforced for extra stiffness and heat resistance, it's used in load-bearing housings, brackets, and enclosures.

- Nylon 6/12 (PA 6/12) – Balances strength with low water uptake, commonly used in tubing systems and protective cable covers.

- Nylon 11 (PA 11) – Naturally flexible and chemically resistant, it's a good fit for fuel hoses, medical parts, and sports gear.

| Tensile Strength, Yield (MPa) | Elongation at Break | Hardness | Impact Strength | Heat Deflection | Heat Deflection Temperature | Melting Point |

|---|---|---|---|---|---|---|

| 70 - 80 MPa | 20 - 300% | Rockwell M70 - M100 | 60 - 100 J/m | 40 - 70 °C | 85 - 95 °C | 220 - 265 °C |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Looking for High-Quality Nylon CNC Machining?

Get high-performance cnc nylon parts—machined to your specs, delivered on time. Upload your CAD file now and receive a fast, competitive quote from our engineering team.

Advantages & Application of CNC Machined Nylon

CNC Machined Nylon Parts Applications

- Gears

- Sprockets

- Bushings

- Bearings

- Insulators

- Electrical housings

- Automotive parts

- Medical equipment

- Lab equipment

Benefits of Nylon Machining

- High strength for load-bearing parts

- Excellent wear and abrasion resistance

- Lightweight for easier handling

- Chemical resistance to oils and fuels

- Low friction for smooth movement

- Stable in humid environments

- Good machinability for complex shapes

- Impact resistant for tough conditions

- Effective electrical insulation

- Cost-effective and easy to process

Surface Finishing Options for CNC Machined Nylon Parts

To enhance the functionality and appearance of custom nylon machined parts, Jiangzhi offers multiple finishing services including polishing, deburring, and coating. These options improve wear resistance, reduce friction, and provide cleaner surface aesthetics tailored to your application.

Standard finish with visible tool marks; suitable for functional prototypes and internal components.

Uses abrasive media to create a uniform matte or satin finish; also improves coating adhesion on plastic or metal surfaces.

Adds logos, text, or identification marks via silk screen or pad printing, ideal for branding or part tracking.

Removes machining marks and evens out surface texture; ideal for prototypes and parts where appearance is not critical.

Painting and powder coating provide colorful, durable, and corrosion-resistant finishes.

Deposits metal layers such as nickel or chrome on parts, improving wear resistance, conductivity, and aesthetic quality.

Produces a smooth, glossy finish; commonly applied to plastics like PC or PMMA for enhanced clarity and premium look.

Chemical treatment for ferrous metals, creating a dark, corrosion-resistant surface with minimal thickness.

Electrochemical process for aluminum that enhances corrosion and wear resistance, with options for colored finishes.

Jiangzhi Nylon CNC Machining Parts Are Guaranteed

FAQs About Nylon CNC Machining

Yes, nylon is machinable nylon with great strength and wear resistance, perfect for functional parts.

Nylon absorbs moisture, which can cause dimensional changes. We dry the material before machining to minimize this impact and ensure stability.

Nylon is easier to machine and better for wear resistance, while PC offers higher optical clarity and impact strength.

Yes, controlling humidity and machining parameters is important to prevent warping and maintain precision.

Nylon parts can be polished or coated to improve surface finish, though they are not transparent.

We offer a satisfaction guarantee. If there's any issue, we’ll remake—no hassle.