EPDM Injection Molding

What is EPDM Injection Molding?

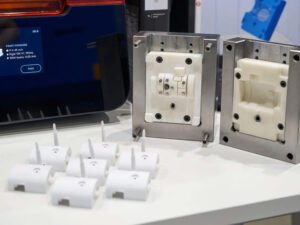

Our EPDM injection molding process begins with custom-designed molds to ensure each part delivers consistent precision and performance. Using advanced injection machines, EPDM rubber is shaped under controlled heat and pressure, followed by careful curing and cooling. Professional finishing ensures every component meets strict dimensional and quality standards, providing reliable results for applications such as automotive seals, HVAC components, and industrial gaskets.

With our expertise in mold design, process optimization, and full-process technical support, we provide scalable and cost-effective EPDM molding solutions. From small-batch prototypes to high-volume production, we guarantee durable, flexible, and reliable custom rubber parts, complemented by engineering guidance, quality assurance, and timely delivery, helping you optimize performance while controlling cost.

Injection Molding EPDM Parameters Table

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 1.5mm – 6mm |

| Maximum Part Size | 400mm × 400mm |

| Minimum Feature Size | 0.8mm – 1.5mm |

| Tolerances | ±0.1mm – ±0.3mm |

EPDM Material Properties

EPDM (Ethylene Propylene Diene Monomer) is a high-performance synthetic rubber widely used in automotive, industrial, and outdoor applications. Chemically, it is composed of ethylene, propylene, and a diene monomer, giving it excellent flexibility, ozone and UV resistance, and long-term aging stability.

- Common Abbreviations: EP, EPR, EPT, EPDM

- Ethylene and Propylene: provide good flexibility and weather resistance

- Diene monomer: allows for vulcanization, improving elasticity and heat resistance

- Performance Classification: Meets ASTM D-2000 standards, typically classified as AA, BA, or CA for automotive rubber applications

- Key Properties: Superior weather and ozone resistance, excellent elasticity, good compression set, and broad temperature tolerance

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| Value/Description | 1.10–1.20 g/cm³ | 7–15 MPa | (rubber, not applicable) | Excellent resilience | ~120 °C (after vulcanization) |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Looking for High-Quality Silicone Injection Molding?

Advantages & Disadvantages of EPDM Injection Molding

EPDM rubber injection molding is highly favored for sealing and insulation due to its excellent environmental resistance and elasticity. However, it also has some trade-offs.

Advantages

- Excellent Weather and Chemical Resistance – Resists UV, ozone, aging, and many chemicals, making it ideal for outdoor use.

- Wide Temperature Stability – Performs reliably under extreme high and low temperatures.

- Water and Steam Resistance – Maintains performance in humid or wet environments.

- Low Electrical Conductivity – Suitable for insulating applications.

- Versatile Applications – Can be used across automotive, HVAC, industrial, and consumer products.

- Durable and Long-Lasting – Provides continuous, reliable performance while reducing replacement costs.

- Cost-Effective – More economical compared with silicone in many applications.

Disadvantages

- Poor resistance to petroleum-based oils and fuels

- Moderate tear resistance

- Adhesion may require surface treatment

Applications of Injection Molded EPDM

Automotive Industry

- Door seals and window gaskets

- Firewall plugs

- Under-hood rubber parts

- Trunk weatherstrips

HVAC & Construction:

- Pipe seals

- Roof flashing gaskets

- Weatherstripping

- Expansion joint covers

Industrial Applications:

- Cable grommets

- Protective bellows

- Vibration dampers

- Electrical enclosures

Consumer & Outdoor Goods:

- Garden hose fittings

- Waterproof rubber boots

- Appliance gaskets

- Sports gear components

Jiangzhi EPDM Injection Molding Parts are Guaranteed

FAQ About EPDM Injection Molding

Cracks often come from stress during cooling, poor mold design, or even using the wrong processing temps. We focus on balanced part design and proper molding conditions to keep your ABS parts crack-free.