POM Injection Molding

What is POM Injection Molding?

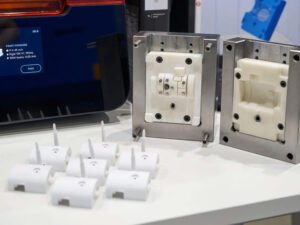

Our polyoxymethylene injection molding process ensures excellent mechanical strength, low friction, and high dimensional stability. Using advanced acetal injection molding techniques, we manufacture Delrin injection molding components with superior wear resistance and durability.

- Mold Design: Precision-engineered molds reduce shrinkage and improve part consistency.

- Processing: POM injection moulding melts acetal resin at controlled temperatures before injecting it into high-precision molds.

- Cooling & Solidification: Well-regulated cooling minimizes warping and ensures structural integrity.

- Post-Processing: Secondary treatments like machining, ultrasonic welding, or coating enhance performance and appearance.

With expertise in POM plastic injection molding, material selection, and process optimization, we provide scalable injection molding POM solutions for industries requiring strength, wear resistance, and low friction.

Injection Molding POM Parameters Table

| Parameter | Recommended Range |

|---|---|

| Wall Thickness | 1.0mm - 6.0mm |

| Maximum Part Size | 1500mm x 1000mm x 600mm |

| Minimum Feature Size | 0.5mm - 1.2mm |

| Tolerances | ±0.02mm - ±0.10mm |

POM Material Properties

Acetal injection molding is widely used for high-strength, low-friction applications. Its excellent wear resistance, chemical stability, and dimensional accuracy make it ideal for demanding environments. Key Material Properties:

- High mechanical strength – Excellent toughness and impact resistance.

- Low friction & wear resistance – Ideal for moving parts, gears, and bushings.

- Dimensional stability – Minimal moisture absorption ensures precision.

- Chemical & fuel resistance – Resistant to oils, solvents, and gasoline.

| Property | Density | Tensile Strength | Flexural Strength | Impact Strength (Unnotched) | Heat Deflection Temp (0.45 MPa) |

|---|---|---|---|---|---|

| Value/Description | 1.41 - 1.43g/cm³ | 55 - 75 MPa | 90 - 120 MPa | 5 - 12 kJ/m² | 90 - 110℃ |

- The above parameters represent the baseline performance of the materials. Actual application should be dynamically optimized based on specific working conditions.

Related Process

Looking for Reliable Acetal Injection Molding?

Advantages & Disadvantages of POM Injection Molding

Delrin injection molding offers excellent mechanical properties, but has limitations in heat resistance and UV stability. Understanding these factors helps in material selection for industrial applications.

Advantages

- High Strength & Stiffness – Withstands stress and deformation in demand.

- Excellent wear resistance – Ideal for gears, bushings, and sliding components.

- Fatigue & Creep Resistance – Maintains structural integrity over time.

- Easy Machining & Post-Processing – Allows drilling, tapping, and welding.

Disadvantages

- Lower heat resistance – Softens at high temperatures (>110℃).

- Poor UV resistance – Degrades when exposed to prolonged sunlight.

- Flammability – Requires flame retardant grades for high-safety applications.

Applications of POM Injection Molding

POM is widely used across industries due to its strength, wear resistance, and low friction. Our polyoxymethylene injection molding services provide high-quality, cost-effective solutions for various applications.

Automotive Industry

- Fuel system components

- Gear wheels & transmission parts

- Door lock systems

- Interior mechanical assemblies

Industrial & Mechanical

- Bearings & bushings

- Conveyor belt components

- Gears & pulleys

- Wear-resistant guides

Consumer Goods

- High-performance zippers

- Kitchen appliance components

- Sports equipment parts

- Electrical connectors

Medical Devices

- Insulin pens & inhalers

- Surgical instrument handles

- Medical gear mechanisms

- Fluid handling components

Jiangzhi POM Injection Molding Parts Are Guaranteed

FAQs About Injection POM Molding

POM is the general term for polyoxymethylene, while Delrin is a trade name for DuPont’s homopolymer POM. Delrin injection molding offers slightly higher strength and toughness, while copolymer POM has better chemical resistance and thermal stability.

Recommendation: Use Delrin for high-stress applications; opt for copolymer POM when chemical resistance is a priority.

Common Causes:

- High residual stress from fast cooling.

- Uneven wall thickness causing shrinkage variation.

- Poor mold design leading to inconsistent cooling.

Solutions:

- Optimize cooling rates and mold temperature (80-120℃).

- Maintain uniform wall thickness to prevent uneven shrinkage.

- Use proper gating locations to ensure balanced flow.

Optimization Strategies:

- Increase mold temperature and injection speed to improve flow.

- Use higher molecular weight POM grades for better bonding.

- Optimize gate location to minimize weld line formation.

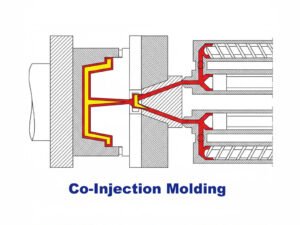

Yes, but it must be paired with compatible materials like TPE or PA.

Key Considerations:

- POM as the core layer for strength and durability.

- TPE or PA as the outer layer for flexibility or soft touch.

- Ensure proper adhesion to prevent delamination.

Yes! POM parts can be CNC machining, drilling, tapping, ultrasonic welding, etc., but note that:

- CNC machining needs to control the cutting temperature to avoid melting

- Ultrasonic welding is suitable for POM+POM connections

- Limited surface treatment (e.g., poor adhesion to spraying and printing)

Want to improve part functionality? We can provide CNC Machining & Assembly services!