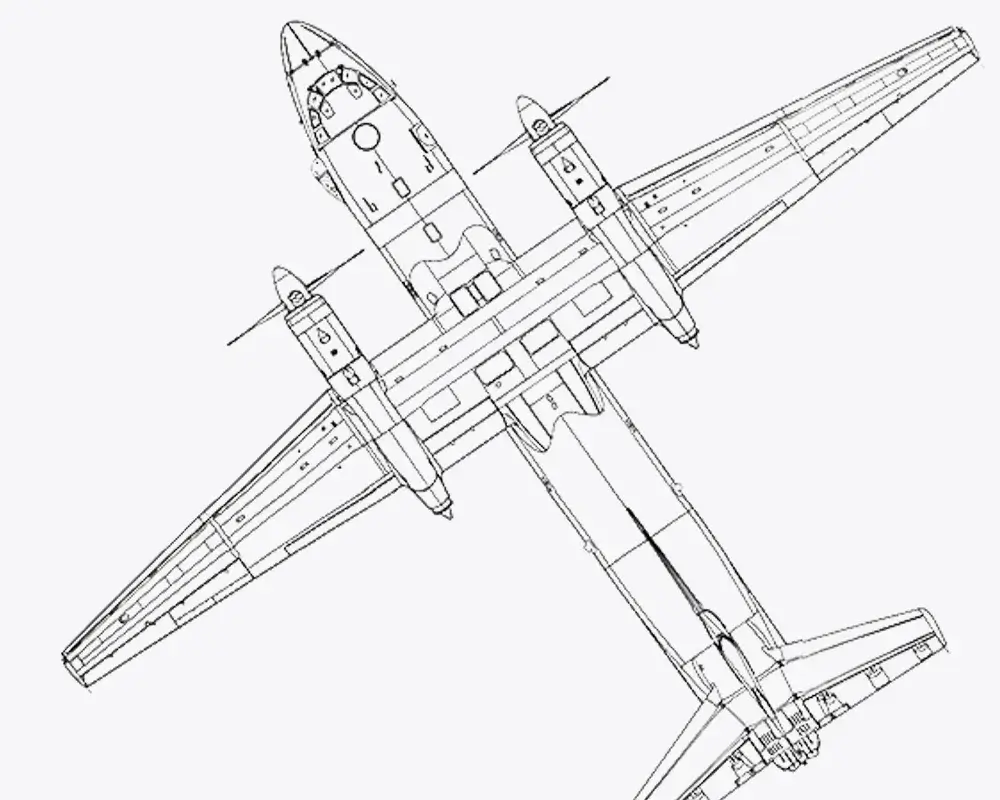

Aerospace Injection Molding Services

- Optimized Design: Improve manufacturability and quality

- Complete Assembly: Fully tested, ready-to-use modules

- Cost Efficient: Save material and production costs

- On-Time Delivery: Reliable, traceable shipments worldwide

Aerospace Injection Molding Capabilities

We offer a comprehensive suite of advanced molding processes designed to meet the stringent precision, lightweight, and high-performance requirements of aerospace components. From intricate structural parts to critical housings, our solutions ensure reliability, efficiency, and scalability for every stage of production.

High-Performance Plastic Solutions for Aerospace and Defense

Jiangzhi provides precision aerospace injection molding services tailored to the stringent requirements of aviation, aerospace, and defense industries. With quality management and advanced molding capabilities, we deliver lightweight, durable, and reliable aerospace components that meet the highest industry standards.

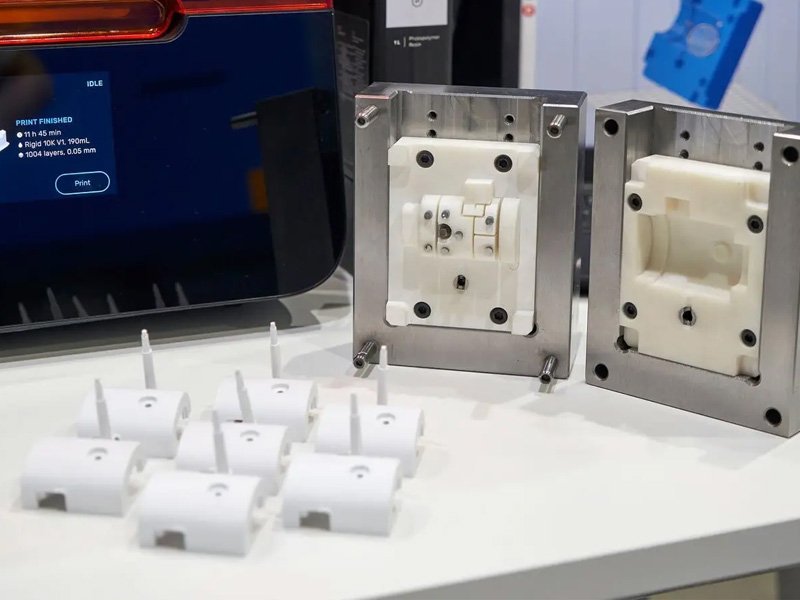

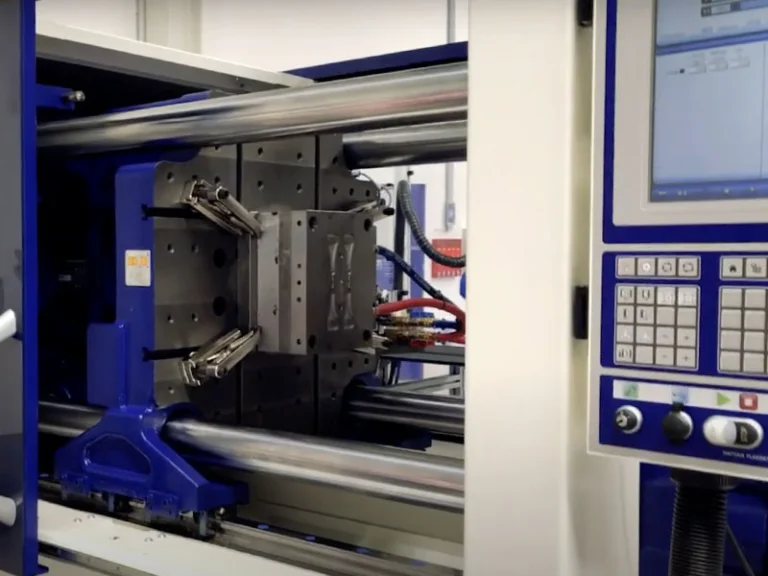

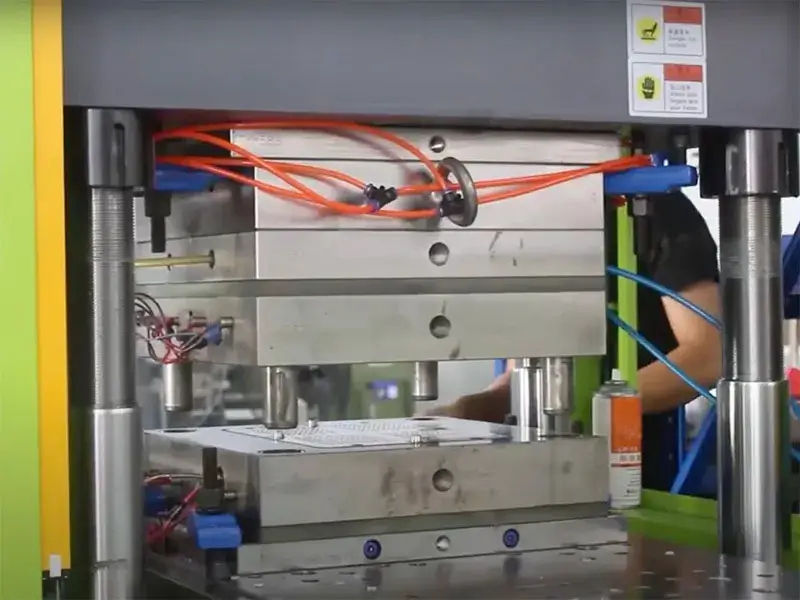

Plastic Injection Molding

Our plastic injection molding efficiently produces high-quality components. With a focus on precision and consistency, we deliver top-notch results for a variety of applications.

Rubber Injection Molding

Opt for superior flexibility and durability with our rubber injection molding service. Tailored for rubber materials, we create resilient components designed for longevity and optimal performance.

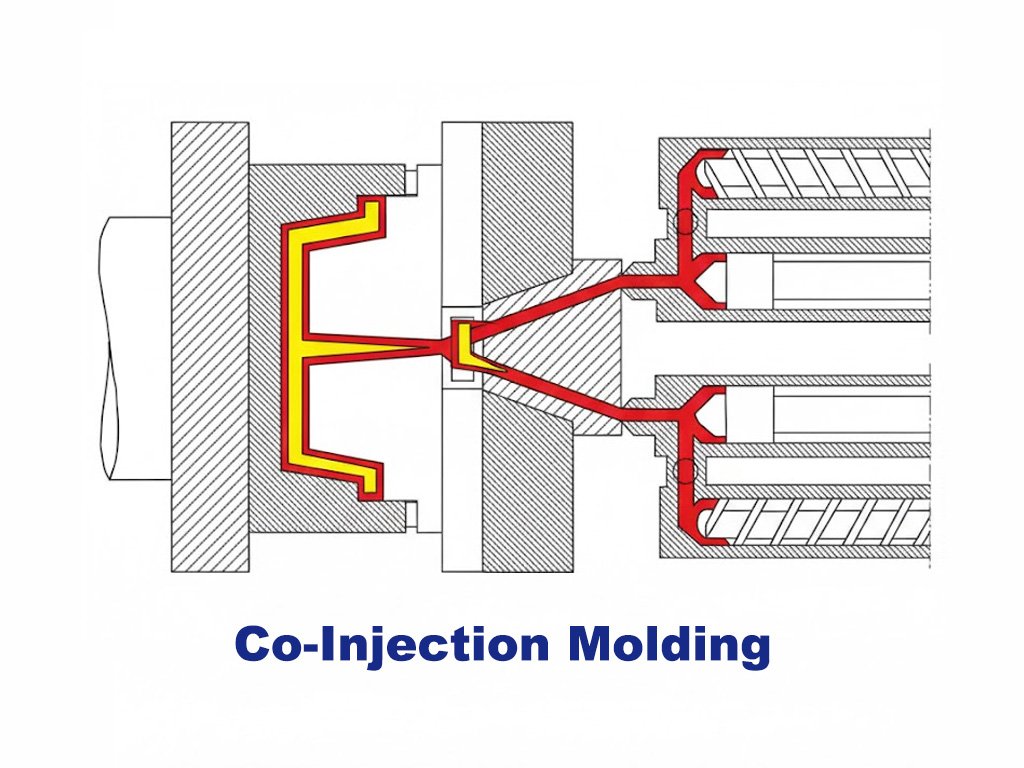

Overmolding & Insert Molding

Enhance product performance and overall visual design with our overmolding and insert molding, creating strong, versatile, multi-material components.

Advanced Materials for Aerospace Applications

We use aerospace-grade plastics with flame-retardant, anti-static, and antimicrobial properties, delivering lightweight strength, durability, and compliance with strict aerospace safety standards. Materials for Aerospace Parts:

Injection Molding Plastic Materials

Injection-molded plastics are strong, precise, and versatile for durable parts.

- PA

- PC

- POM

- PE

- PTFE

Injection Molding Rubber Materials

Injection molding rubber creates flexible, durable, impact-resistant parts.

- EPDM

- NBR

- MVQ

Aerospace Applications & Typical Components

Our injection molded components are widely used in aerospace interiors, structural systems, and electronic assemblies, including:

- Cabin interior parts: seat components, overhead bin latches, ventilation panels.

- Electrical housings: sensor casings, navigation equipment enclosures.

- Structural brackets, fasteners, and mounting clips.

- Ducting, air management, and lightweight covers.

- Connectors, cable clamps, and protective housings.

Engineering Support & Design Optimization Expertise

Jiangzhi’s engineering team provides full design-for-manufacturability (DFM) and technical support throughout the project lifecycle.

Partner with Jiangzhi for Aerospace Injection Molding

Partner with Jiangzhi for Aerospace Injection Molding. Achieve lightweight, high-performance, and reliable aerospace parts with our advanced technology and certified materials.