Automated Injection Molding Solution

Click to View

What is Automated Injection Molding?

Automated Injection Molding is the use of robotics, intelligent controls, and automated systems to perform key steps of the injection molding process with minimal human intervention. This includes material loading and unloading, insert and overmolding, part removal, assembly, sorting, stacking, trimming, finishing, visual inspection, and packaging.

Automation in Jiangzhi’s Injection Molding Process

Advanced automation is fully integrated into our high-performance injection molding systems to ensure stable, efficient, and flexible production. The automated workflow covers every stage, from material handling to final inspection, guaranteeing consistent quality and productivity.

Part Picking and Handling

Downstream Processing

Intelligent Control

Faster, Consistent, Cost-Effective Injection Molding

Benefits of Automated Injection Molding

Automated injection molding leverages robotics, intelligent controls, and integrated systems to streamline the entire molding process. By minimizing manual intervention, it delivers multiple advantages:

- Faster, More Reliable Production

Continuous automated operation shortens lead times, minimizes downtime, and ensures every order is delivered on schedule.

- Consistent Quality You Can Trust

Robotic precision and real-time inspection guarantee uniform, defect-free parts for stable, high-quality performance.

- Lower Costs and Greater Efficiency

Automation reduces manual labor, material waste, and energy use directly cutting overall production expenses.

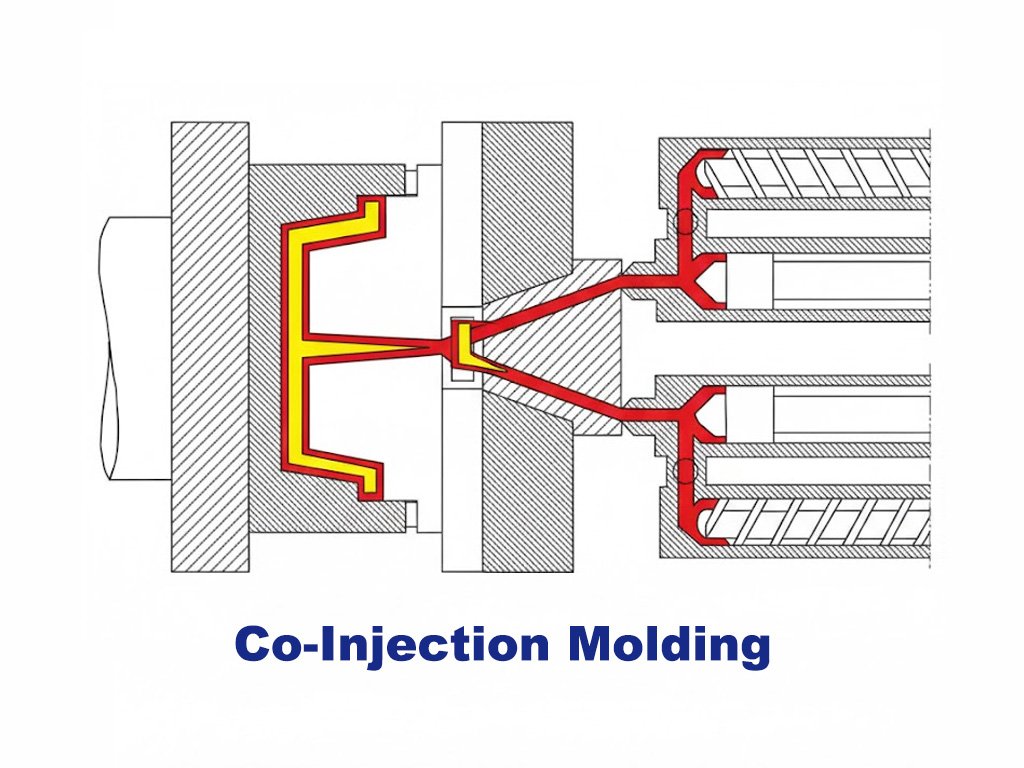

- Flexibility for Complex and Scalable Projects

Easily adapts to overmolding, insert molding, and assembly tasks, making it ideal for diverse product designs and volume demands.

Why Choose Jiangzhi as Your Injection Molding Manufacturing Partner?

High Precision & Consistent Quality

Fast Turnaround & Flexible Capacity

Expert Engineering Support

One-Stop Prototyping & Small-Batch Solution