Custom Cast Molding Services

Cast Urethane Molding Services

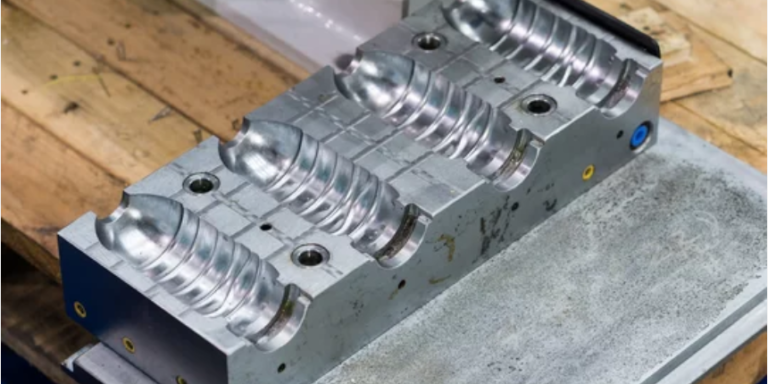

We offer custom cast urethanes using durable metal molds to ensure consistent quality and dimensional accuracy. Unlike soft silicone molds commonly used in traditional urethane casting service, our metal molds support repeated use and deliver reliable performance for high-quality short-run production. Our cast urethane molding services support:

- Complex geometries and undercuts

- Varying hardness (shore A to shore D)

- Transparent or pigmented finishes

- Insert molding and overmolding

- Tight tolerance control

Our Cast Molding Capabilities

| Name | Detail |

|---|---|

| Size |

98.42in. x 78.74in. x 39.37in. 2500mm x 2000mm x 1000mm |

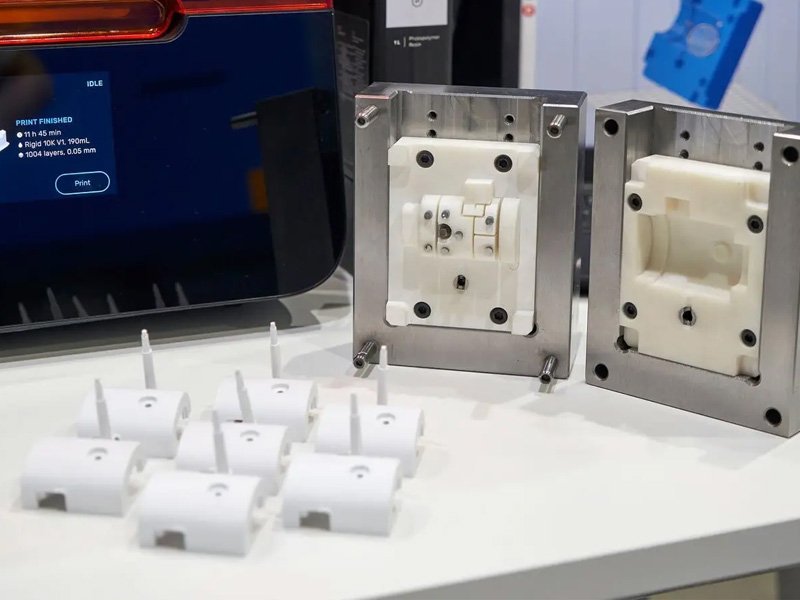

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

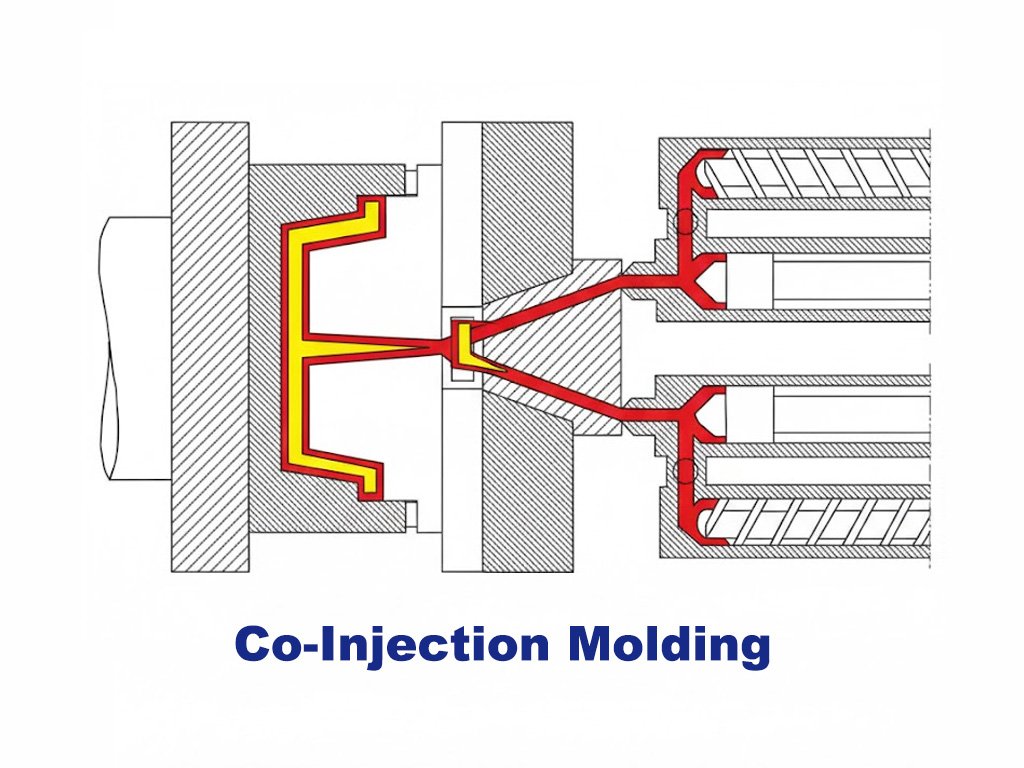

How Does Cast Molding Work?

Metal Mold Setup & Surface Prep

Material Selection & Urethane Mixing

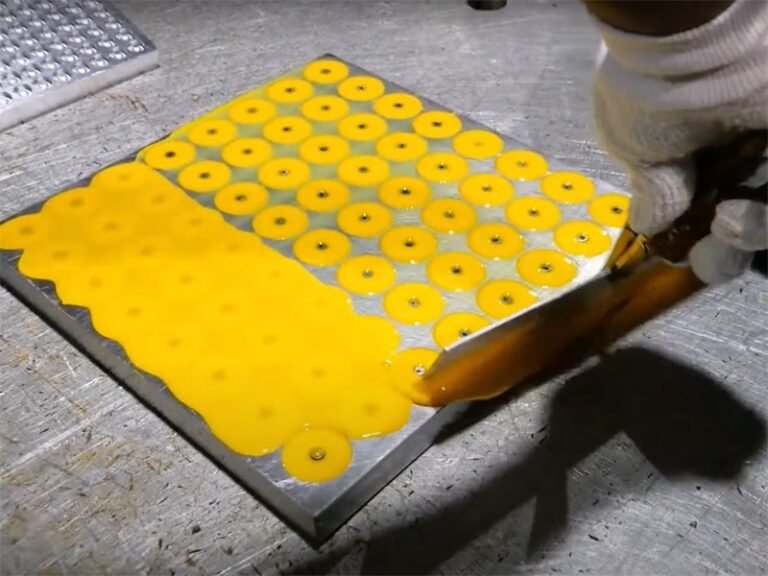

Casting, Curing & Demolding

Inspection, Post-Processing & Delivery

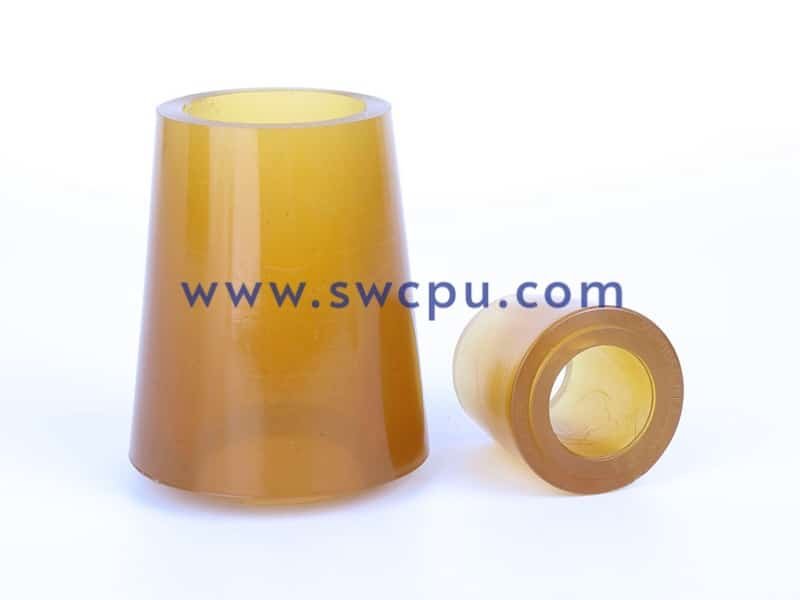

Cast Molding Parts Examples

Custom Contract Manufacturing Capability

Advantages of Cast Molding

From product development models and prototypes to low-volume production runs, this rapid prototyping process is capable of producing parts that are highly similar in color, texture, feel and physical properties to injection-molded parts.

- Offers a wide variety of material choices such as rigid, flexible, durable, transparent, and high temperature resistance

- Offers physical properties similar to injection molded parts

- Suitable for low volume production

- Ability to re-mold an existing part or hardware using another material

Cast Molding Application

Cast molding is a manufacturing process with broad spectrum of applications, ranging from automotive and industrial components to medical devices and consumer products.

- Seals and gasket

- Urethane rollers

- Custom o-ring

- Vibration dampers

- Grommets and bushing

Urethane Cast Molding Parts in Different Industries

Why Choose Us for PU Casting Service?

High Precision & Consistent Quality

Fast Turnaround & Flexible Capacity

Expert Engineering Support

One-Stop Prototyping & Small-Batch Solution

One-Stop PU Casting Molding Manufacturer

FAQs of Cast Molding

Why choose polyurethane casting instead of 3D printing?

Polyurethane casting produces stronger, more durable parts with better surface finish. It’s cost-effective for small batches and functional prototypes, while 3D printing is slower and often less durable.

Why choose polyurethane casting instead of injection molding?

What types of parts are suitable for PU Casting?

PU Casting works well for low-volume or custom parts, functional prototypes, and engineering samples.