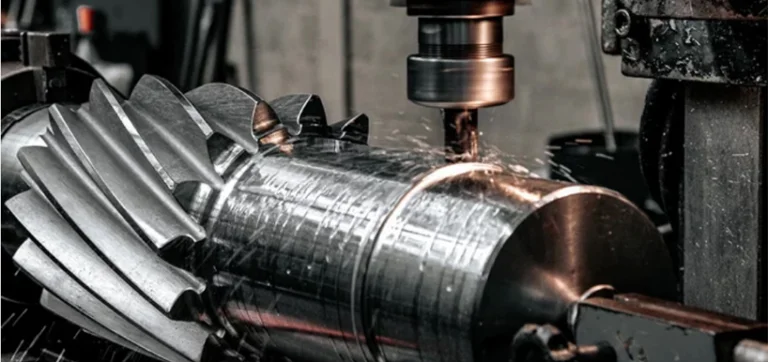

CNC Turning Service

Jiangzhi offers custom CNC turning services for both prototypes and high-volume production. Our advanced machinery ensures precise, high-quality results for complex cylindrical parts. With competitive pricing starting at just $50 per part, we deliver cost-effective CNC machining solutions tailored to your specific needs. Plus, our expert team works with a variety of materials to bring your design to life with accuracy and efficiency.

What is CNC Turning?

CNC Turning Capabilities

CNC Turning General Tolerances

| Description | General Tolerance |

|---|---|

| Distance Dimensions | ±0.1 mm (length, width, height, diameter, position, concentricity, symmetry) |

| Orientation & Form | ±0.1–2 mm, depending on part size |

| Angularity | ±0.5° |

| Edge Condition | Deburred by default unless otherwise specified |

Machining Limits

| Part size limitations | Capacity |

|---|---|

| Maximum part diameter | 431 mm (17 in) |

| Maximum part length | 990 mm (39 in) |

| Maximum swing over the carriage | 350 mm (13.7 in) |

| Maximum spindle through-hole | 40 mm (1.5 in) |

Notice: Tighter tolerances are available upon request, depending on material and geometry.

CNC Turning Services Materials

Aluminum Alloys

- 6061 Aluminum – Used for lightweight shafts, spacers, and cylindrical components.

- 6063 Aluminum – Suitable for cosmetic turned parts.

- 7075 Aluminum – Used for high-strength aerospace bushings.

Stainless Steel

- 303 Stainless Steel – Ideal for precision turned fittings and fasteners.

- 304 Stainless Steel – Used in food-grade and medical cylindrical components.

- 316 Stainless Steel – Applied in marine and chemical environments.

- 17-4PH Stainless Steel – Used for high-strength shafts and connectors.

Carbon & Alloy Steel

- 1018 / 1020 Steel – Suitable for general-purpose shafts and pins.

- 1045 Steel – Used for wear-resistant turned components.

- 4140 / 4340 Steel – Applied in high-load shafts and transmission parts.

- 12L14 Free-Cutting Steel – Ideal for high-volume precision turned parts.

ToolCopper & Brass

- Brass C360 – Common for fittings, connectors, and decorative components.

- Copper C110 – Used for electrical and conductive parts.

- Phosphor Bronze C544 – Applied in bushings and bearing components.

Plastics Material

- POM (Acetal) – Used for precision bushings and rollers.

- Nylon – Suitable for lightweight turned components.

- PTFE – Applied in seals and chemical-resistant parts.

- UHMW-PE – Used for low-friction guide components.

- ABS – Suitable for low-load plastic turned parts.

How CNC Turning Works?

Workpiece Setup

Programming & Toolpath

Turning & Material Removal

Finishing

Inspection & Delivery

Top 10 CNC Machining Benefits

Why Choose Us?

Ensuring accurate and intricate part production

Meeting diverse industry needs

Proven track record in successful projects

Rigorous quality checks for reliable results

Professional CNC Turning Service Company

FAQs of CNC Milling

What are the limitations of CNC turning?

CNC turning has some limitations like design restrictions. CNC turning is ideal for creating rotational, symmetric parts. But other methods such as CNC milling might be more appropriate for non-cylindrical parts.

What is the basic principle of CNC turning process?

As the piece rotates, a cutting tool is fed to the piece, which works at the material, cutting away to create the desired shape. Unlike other cutting sytles where the cutting tools themselves move and spin, in this case, the workpiece is rotated during the cutting process.

What materials are used in CNC turning?

The most common CNC turning materials include: aluminium, stainless steel, copper, brass, steel alloy, and various plastics.

How many types of CNC turning are there?

There are two broad categories of CNC turning centers, which include horizontal turning centers and vertical turning centers. Horizontal turning centers are far more common than their vertical counterparts.