High Volume Injection Molding Service

Click to View

High-Volume injection Molding is a manufacturing process that efficiently produces large quantities of precise plastic parts by injecting molten plastic into molds under high pressure and temperature. It offers cost advantages for high-volume projects, as unit costs decrease with production scale. The process supports a wide range of plastic materials, providing flexibility for different applications.

Is High-Volume Injection Molding Right for Your Project?

- You need to produce 100000 or more parts annually to lower unit costs.

- Your product design is stable and finalized, minimizing changes during production.

- Consistent, high-quality parts with tight tolerances are critical to your application.

- Your production demands automated, efficient processes to meet large-scale volumes.

- You seek a dependable manufacturing partner for ongoing, long-term supply.

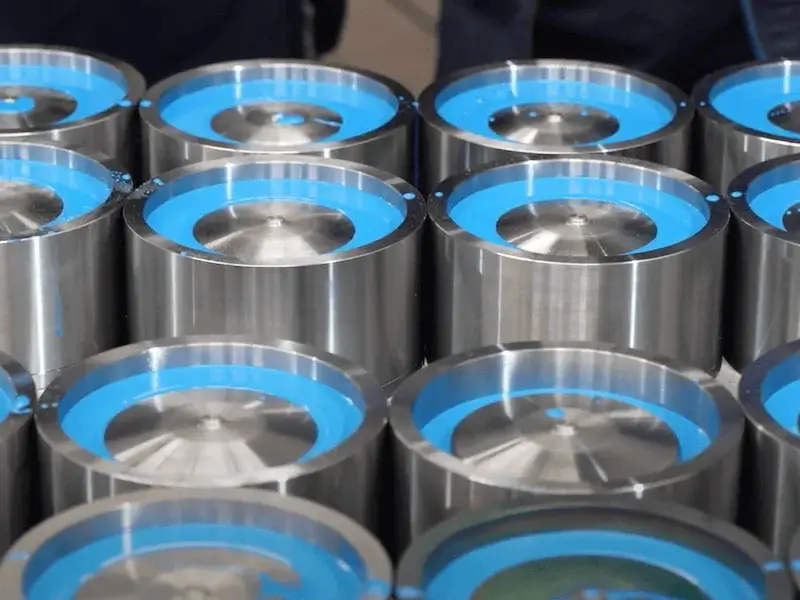

At Jiangzhi, our high-volume injection molding services make it easy to get precise, consistent, and cost-effective plastic and rubber parts in large quantities. Our advanced facility is equipped with injection molding machines ranging from 50 to 1200 tons, supported by durable molds engineered for millions of cycles.

Your High Volume Injection Molding Manufacturer!

Injection Molding Solutions for High Volume

- Standard Injection Molding

Mature and stable process, ideal for mass production of most plastic parts.

- High-Pressure Injection Molding

Provides fast filling and high precision, suitable for large-scale manufacturing of complex or thin-walled parts.

- Large Part Injection Molding

Designed for large and complex components, commonly used in the automotive and appliance industries, with high volume demand.

- Small Part Injection Molding

High-precision production of small components is widely used in electronics and the medical sectors for large batches.

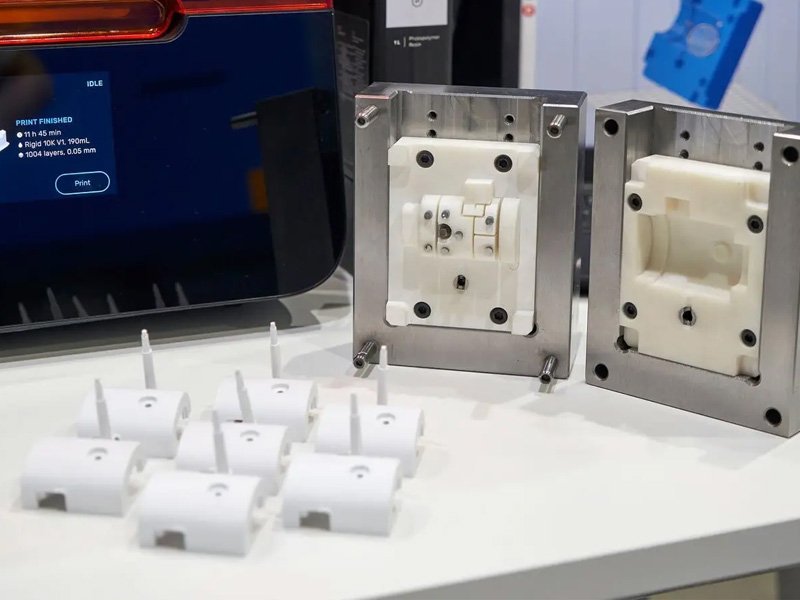

- Multi-Cavity Molding

Multiple cavities in a single mold allow simultaneous production of multiple parts, greatly increasing output per cycle.

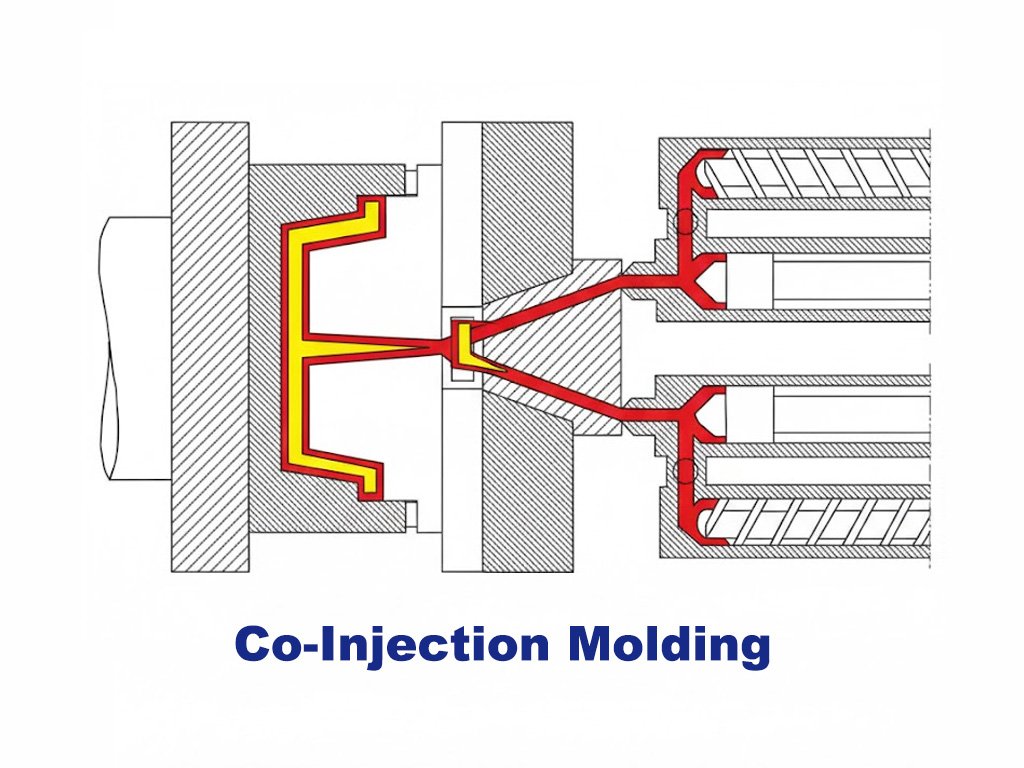

- Overmolding

Combines multiple materials in one part; suitable for medium to high volume production, though mold complexity is higher.

- Insert Molding

Embeds metal or other inserts during molding; efficient for large-scale production of composite parts.

- Gas-Assisted Injection Molding

Creates hollow sections to reduce weight; appropriate for high volume if the design is optimized.

- High-Temperature Injection Molding

Used for high-performance engineering plastics in large production runs.

- Thin Wall Injection Molding

Focuses on ultra-thin parts for lightweight applications, effective in mass production.

The Advantages of High Volume Injection Molding

- Fast production of large quantities.

- Consistent and precise part quality.

- Lower unit cost and reduced labor.

- Automated operation around the clock.

- Minimal post-processing required.

- Flexible design with multiple material options.

High Volume Injection Molding Applications

Automotive: Interior and exterior components, engine parts.

Medical Devices: Syringes, diagnostic equipment housings.

Consumer Electronics: Smartphone casings, buttons, bezels.

Household Appliances: Kitchenware, vacuum cleaner parts.

Packaging: Bottles, caps, containers.

Toys and Games: Plastic figures, game pieces.

Industrial Components: Connectors, housings, enclosures.

Aerospace: Cabin parts, ventilation systems.

Agriculture: Water tanks, feed containers, and cleaning equipment.

Other Options for High Volume Manufacturing

Compression Molding

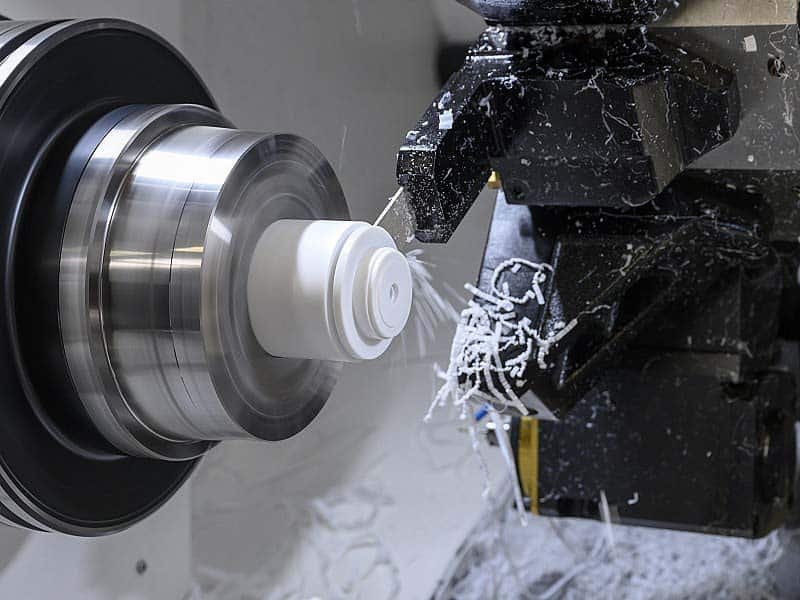

CNC Turning

CNC Milling