High-Volume Manufacturing Services

Click to View

We provide end-to-end high-volume manufacturing solutions that take your design from mold to production. Common processes for large-scale production are injection molding, CNC machining, polyurethane casting, and compression molding.

Whether you need volume manufacturing for tens of thousands or millions of units, our high-volume contract manufacturing team ensures every custom plastic part or rubber part meets your exact specifications on time and within budget.

What is High Volume Manufacturing?

High-volume manufacturing refers to producing large quantities of identical parts using highly efficient, automated processes. This type of high-volume production is the preferred choice for industries requiring consistent quality, tight tolerances, and low per-unit costs. Common applications include:

- Automotive: engine components, interior parts

- Medical devices: housings, surgical instruments

- Consumer electronics: enclosures, connectors, accessories

- Household appliances: casings, knobs, mechanical components

- Industrial equipment: gears, fasteners, fittings

Start Your High Volume Manufacturing Project!

Our High-Volume Manufacturing Solutions

We combine diverse production methods, state-of-the-art machinery, and stringent quality control to deliver excellence at scale.

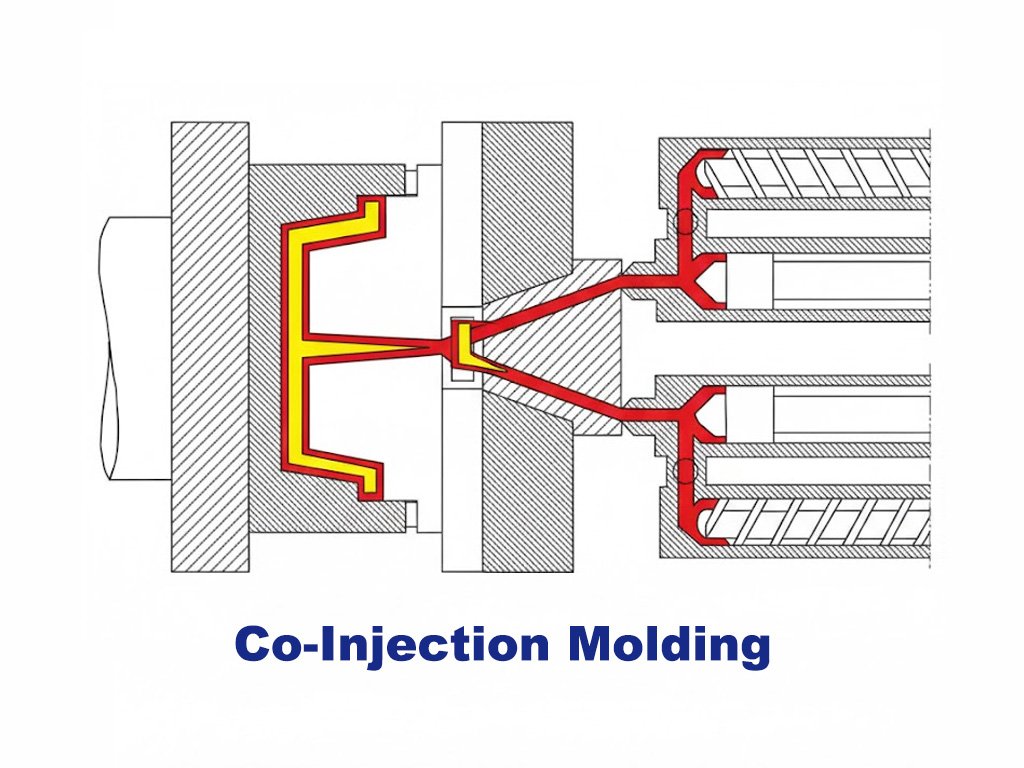

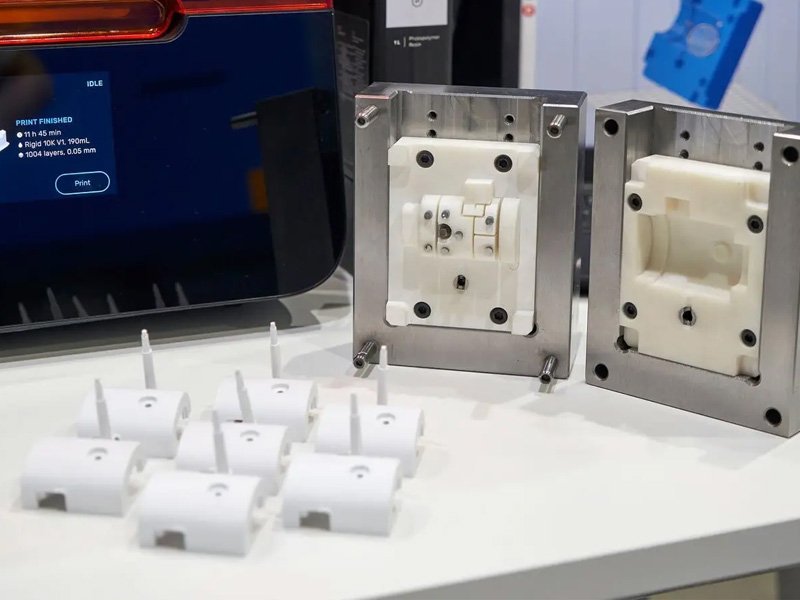

Injection Molding

Efficiently produces millions of precise and consistent plastic and rubber parts once the mold is finalized. Ideal for complex geometries and a wide range of thermoplastic and elastomeric materials.

Advantages: Fast cycle times, scalable production, low per-unit cost, excellent repeatability, and customizable surface finishes.

CNC Machining

High-precision milling, turning, drilling, and grinding for both metals and plastics. Perfect for parts requiring tight tolerances and complex features.

Advantages: Flexibility in materials and design, rapid prototyping to full production, and excellent dimensional accuracy.

Compression Molding

Suitable for high-strength thermoset plastics and composite materials. Offers excellent mechanical properties and stability for durable parts.

Advantages: Cost-effective for medium to large batches, uniform part quality, and ideal for heat-resistant components.

Extrusion

Continuous process is ideal for producing long lengths of uniform cross-section parts such as tubes, pipes, profiles, and sheets.

Advantages: High throughput, consistent cross-sectional quality, suitable for a variety of thermoplastics, and efficient for long-run production.

Why Choose Jiangzhi for High Volume Production?

- Scalable Production: Jiangzhi can efficiently produce thousands to millions of plastic, rubber, and metal parts, meeting the demands of large-scale projects.

- Advanced Technology: Our facilities are equipped with multi-axis CNC machines, high-tonnage injection molding presses, and automated systems to deliver precise, consistent, and high-speed production.

- Skilled Engineering Team: Experienced engineers optimize designs, materials, and manufacturing processes to ensure every part meets exact specifications.

- Streamlined Workflow: From material handling to processing, assembly, and packaging, every step is designed to maximize efficiency, reduce lead times, and minimize waste.

- Cost-Effective Solutions: Process optimization and economies of scale help lower per-unit costs for large-volume orders.

- Flexible Production Management: Multiple production lines and dedicated account support allow simultaneous projects and smooth coordination to meet tight deadlines.

FAQs About High Volume Manufacturing

Typical materials include thermoplastics (ABS, PP, PC, Nylon), elastomers (rubber, TPE), metals (aluminum, steel, zinc alloys), and composites.

Consider the product’s design, mechanical requirements, expected production volume, and budget. Each material performs differently under stress, heat, and wear.

High initial tooling costs, long setup times, inventory management, and limited flexibility for design changes.

Major changes are difficult and costly after production begins. It’s best to finalize designs before high-volume manufacturing.