Low Volume Manufacturing Services

- Pilot or prototype runs

- Customized or limited editions

- Short product lifespans

- On-demand spare parts

Click to View

Are you struggling to find a reliable partner for low-volume production? Many manufacturers focus on large orders, causing delays in prototyping and early market testing. Jiangzhi provides one-stop manufacturing from prototyping and low-volume runs to full-scale production, removing the hassle of changing suppliers.

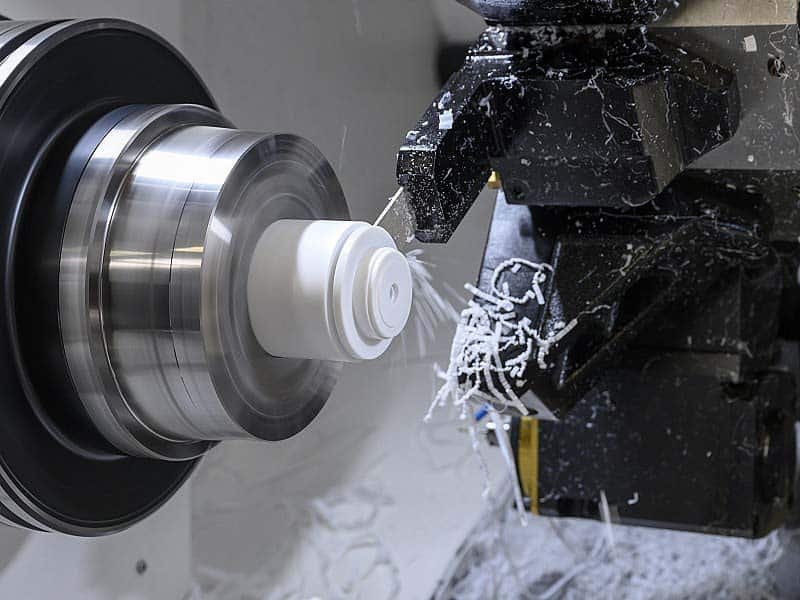

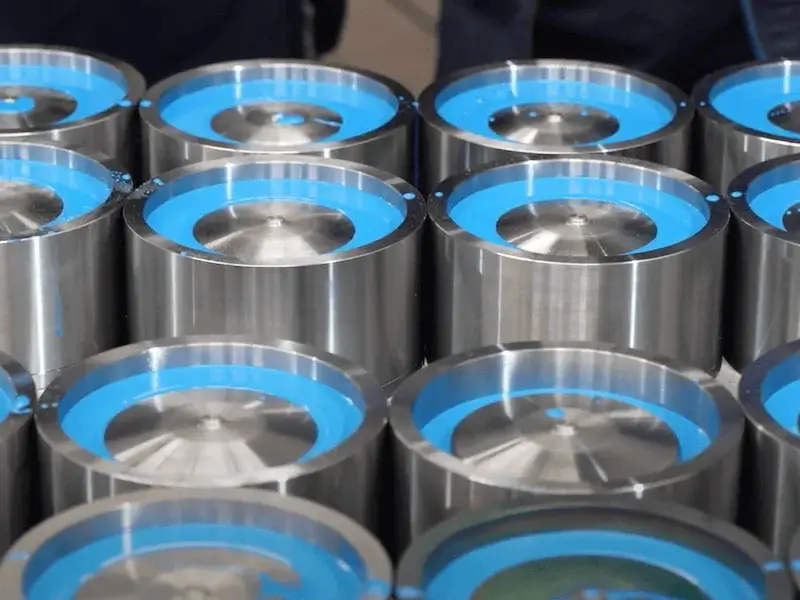

With expertise in CNC machining, injection molding and compression molding products, we work with various plastics and metals to deliver precise, high-quality small volume parts. We have supported tens of thousands of companies in medical, automotive and consumer electronics to turn ideas into products faster and shorten time-to-market.

What is Low Volume Manufacturing?

Low volume manufacturing is the production of small quantities of end-use parts—usually between 50 and 100,000 units—using production-grade materials and manufacturing methods. It acts as a bridge between prototyping and large-scale manufacturing, giving businesses the ability to validate designs, meet early market demand, and avoid overproduction.

Start Your Low Volume Manufacturing!

Small Volume Production Solutions

Injection Molding

CNC Machining

Compression Molding

Polyurethane Casting

Materials for Low Volume Manufacturing

We offer a wide range of materials for low-volume injection molding production, enabling you to create fully functional, production-grade parts before scaling up to mass production.

- Plastics: ABS, PC, PP, Nylon, PMMA, TPU

- Elastomers: Silicone, EPDM, NBR, PU

- Metals: Aluminum, Stainless Steel, Brass, Copper

Quality Assurance in Low Volume Production

Low-volume manufacturing does not mean compromising on quality. Jiangzhi ensures every part meets exact specifications, delivering reliable, production-grade results even in small runs.

- ISO-certified quality control

- Dimensional and functional inspections for every batch

- Material traceability for performance consistency

- Process validation to minimize defects

Advantages of Low-Volume Manufacturing

Low-volume manufacturing quickly turns prototypes into quality parts, reduces risk, and adapts to market changes.

Bridge Production

It bridges prototyping and mass production, letting you test and refine designs, bring production-grade parts to market quickly, and cut financial risk with short runs.

On-Demand Production

On-demand production delivers high-quality parts in days, enabling rapid response to demand changes, supporting urgent or line-down situations, and preventing excess inventory.

Short-Term Production Needs

Ideal for short-term needs, it provides end-use parts, maintenance and operational components, and custom jigs or fixtures, helping prevent downtime and manage inventory efficiently.