Overmolding Service

Jiangzhi offers custom overmolding services for both low-volume and high-volume production. Using advanced overmolding technology, we integrate multiple materials to create durable, high-performance overmolding parts. From overmolding examples in electronics to automotive and medical devices, we provide tailored solutions for various industries. Our efficient overmolding process ensures the best fit with a wide range of substrates and elastomers. With tooling costs starting at just $500, we deliver cost-effective solutions that meet your budget and production timelines. Get in touch today for a custom over molding quote.

What is Overmolding?

Overmolding is a flexible plastic molding process that combines a second material like rubber or plastic directly onto a base part. The result is one complete part with better grip, comfort, and longer life. This one-step process removes extra assembly work and is perfect for handles, tools, electronic cases, and industrial parts that need strong performance.

Plastic overmolding adds strength and shock protection, while rubber overmolding gives a soft feel and reduces vibration. As your custom manufacturing partner, we match materials and methods to your needs, producing complete, high-quality overmolded parts in one efficient step.

Overmoulding Services Capabilities

| Name | Detail |

|---|---|

| Size |

200×400×100mm - 2×2×2mm 7.87×15.75×3.94 in. - 0.08×0.08×0.08in. |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| General Tolerance |

+/- 0.025 mm +/- 0.00098 in. |

| Wall Thickness |

From 0.5 to 3mm From 0.20 to 0.12 in. |

| Radius |

0.1mm 0.0039in. |

| Depth |

100mm from the parting line 3.94 in. from the parting line |

| Lead Time | Starts at 7-14 business days |

Overmolding Service Materials

Bonding Material for Overmolding

The most common overmolded material is thermoplastic elastomer, known for its flexibility, resilience, and compatibility with various substrates. Some common bonding materials include:

- TPE

- TPU

- TPV

- Silicone

Overmolding Material Selection Guide

How Does Overmolding Process Work?

Prepare the Substrate

The substrate, made from plastic, metal, or composite, is cleaned and pre-treated to enhance adhesion and ensure a strong bond during molding.

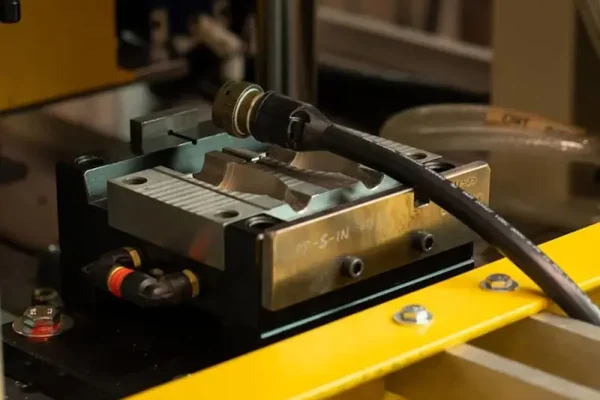

Insert the Substrate into the Mold

The prepared substrate is accurately positioned into a custom mold, either manually or through automation, to ensure precise alignment and prevent defects.

Inject the Overmold Material

Soft or functional materials such as TPE, TPU, or silicone are injected over the substrate to form a durable mechanical or chemical bond that enhances grip, sealing, or impact resistance.

Cooling and Part Ejection

The molded part is cooled to solidify the overmolded layer, then carefully ejected to avoid warping or incomplete bonding.

Post-Processing and Quality Inspection

Excess material is trimmed, and each part undergoes visual and functional inspection to verify it meets quality and performance standards.

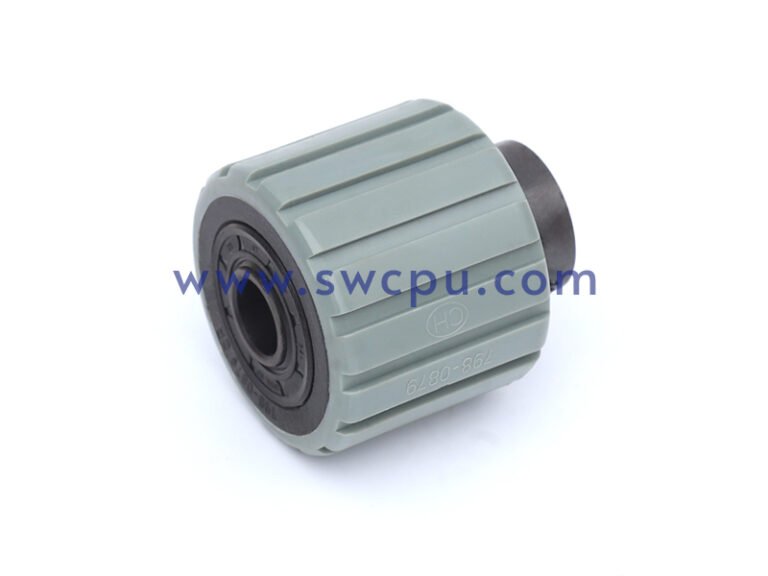

Overmolding Injection Molding Products

Custom Contract Manufacturing Capability

Advantages of Overmolding Service

Overmolding's benefit lies in its ability to fuse dissimilar materials in a single molding cycle, delivering enhanced protection, comfort, and assembly-free production without secondary operations.

- Adds a protective layer for longer product life

- Combines multiple materials in a single part

- Delivers soft-touch comfort for better grip

- Molds complete parts—no extra assembly needed

Application of Overmolding Process

Overmolding service is widely used across various industries due to its ability to enhance product functionality and aesthetics by combining multiple materials. Common applications include:

- Cable connectors

- Soft-touch grips on devices

- Buttons

- Handles

- Protective housing

- Toothbrushes

Overmolding Parts in Different Industries

Why Choose Us Overmolding Service?

High Precision & Consistent Quality

Fast Turnaround & Flexible Capacity

Expert Engineering Support

One-Stop Prototyping & Small-Batch Solution

Professional Overmolding Services Provider

FAQs About Overmolding

What is the difference between overmolding and insert molding?

Overmolding puts a soft material like rubber over a part for grip or comfort, while insert molding embeds a metal or plastic piece into plastic for added strength. The choice depends on what your project needs.

What is low pressure overmolding?

Low pressure overmolding is a specialized overmolding process where a secondary material is injected over a base part at lower injection pressures compared to traditional overmolding. This method is typically used for more delicate or complex parts where high pressure might cause damage or deformation.

Can I use overmolding for complex designs?

Yes! Overmolding is ideal for custom overmolding solutions and complex designs. Whether you need to combine multiple materials or create overmolded plastic parts, our process can achieve high-quality, functional products tailored to your specifications.

What are the benefits of rubber overmolding?

Rubber overmolding adds a comfortable, soft touch to products while improving grip and ergonomics. It’s commonly used for overmolded handles and medical devices, offering durability and a better user experience.

How long does the overmolding process take compared to injection molding?

The overmolding process typically takes longer than injection molding because of the additional steps involved, including the injection of the second material. However, the difference in time may not be significant for small to medium batch runs, and the time investment may be justified by the improved performance