Automotive Injection Molding Services

Comprehensive Automotive Injection Molding Services

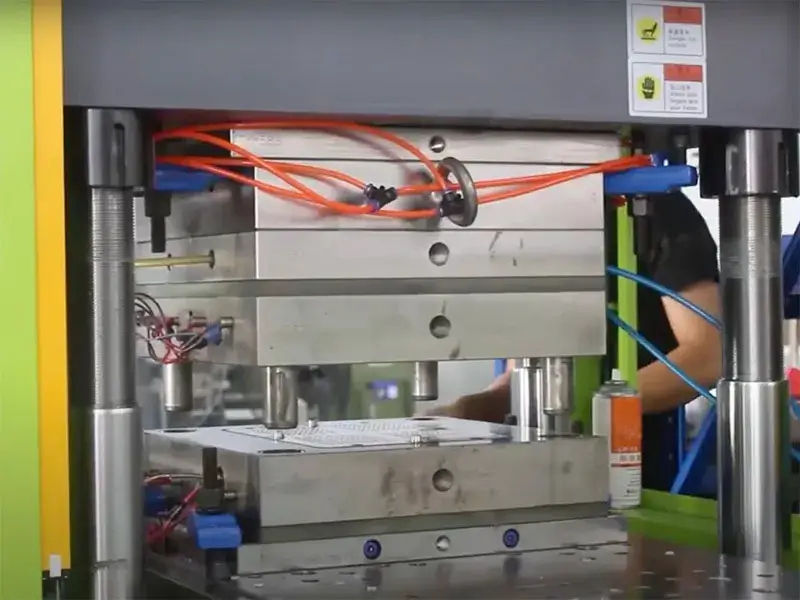

With the growing demand for customized plastic automotive parts, Jiangzhi leverages years of experience in automotive injection molding to provide high-quality solutions for OEMs. From large parts to small parts injection molding, we support every step of the injection molding process, from prototype development to high-volume manufacturing. Our expertise extends to complex custom rubber parts for critical systems like braking, cooling, fuel delivery, and powertrain systems. We provide durable, high-quality parts that meet automotive standards, driving the swift delivery of safe and innovative vehicles.

- Design Optimization Support – Early DFM reviews, mold flow analysis, and rapid prototyping to reduce costs and risks.

- Flexible Tooling Options – Prototype molds, bridge tooling, and multi-cavity production tools to suit different project stages.

- Process Expertise – Scientific molding, automation, and secondary operations such as Surface finishes and assembly.

- Rapid Response – Digitalized workflows, quick quoting, and fast delivery to accelerate product development.

Automotive Injection Molding Capability

Plastic Injection Molding

Rubber Injection Molding

Overmolding & Insert Molding

Start Your Automotive Parts Project with Jiangzhi!

Material Selection for Automotive Applications

Thermoplastics

Thermoplastics offer strength, light weight, and recyclability, making them ideal for cost-efficient, sustainable automotive parts.

- ABS

- PP

- PC

- PA

- TPE

Rubbers

Rubber offers flexibility, impact resistance, and weatherproof sealing, ideal for gaskets, bushings, and vibration-damping automotive parts.

- EPDM

- NBR

- MVQ

- CR

- NR

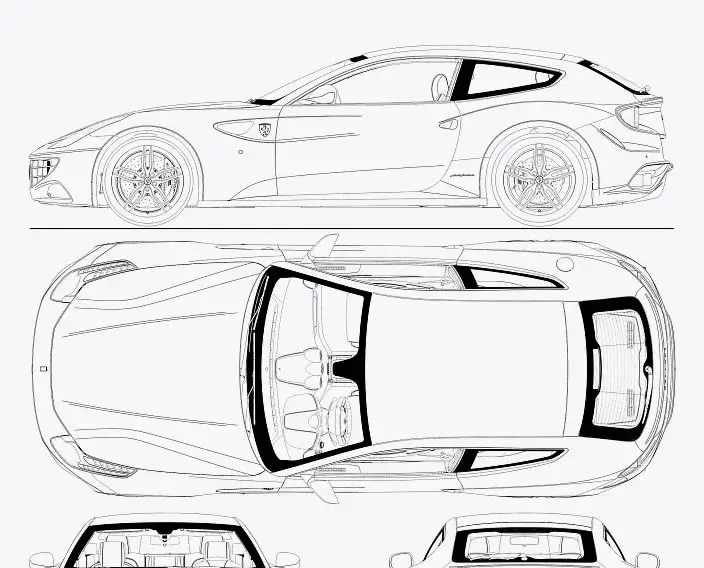

Common Automotive Injection Molded Products

Jiangzhi’s automotive injection molding solutions cover a wide range of essential components, from interior parts to exterior body elements, ensuring precision and performance through advanced injection molding technology.

- Dashboard

- Center Console Panel

- Air Vent Louvers

- Door Trim Panel

- Door Handle

- Knobs & Control Switches

- Front/Rear Bumper

- Body Molding / Trim Strip

- Brackets & Mounts

- Clips, Fasteners & Retainers

- Headlight / Taillight Housing

- Light Guide / Light Pipe

- Battery Enclosure (EV Battery Case)

- ECU / Electronic Module Housing

Advantages of Automotive Injection Molding

Cost-Efficiency

High Precision

Design Flexibility

Low Labor Requirement

Material Efficiency

Scalable Production