Plastic Manufacturing Services

Click to View

Jiangzhi delivers professional plastic manufacturing services backed by 40+ years of manufacturing experience and thousands of successful plastic parts projects. From prototype to production, Our DFM support helps ensure your product is manufacturable, offering guidance on plastic material choice, machining feasibility, and surface finishing and assembly considerations. With advanced CNC and injection molding equipment, we deliver complex plastic components with tight tolerances, precise deburring, and high-quality surface finishes.

Plastic Manufacturing Service Solution

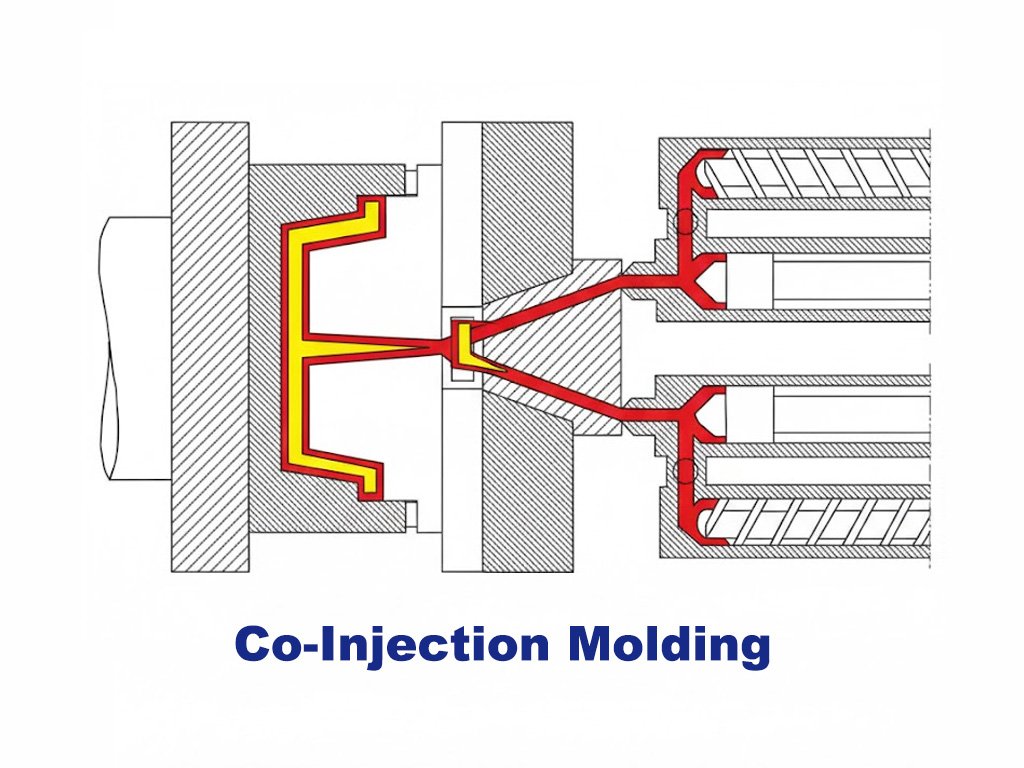

1. Injection Molding

Molten plastic is injected into a mold and shaped under pressure. After cooling, the part is ejected. Ideal for high-volume components like electronics housings, medical devices, and automotive parts. Offers precise dimensions and surface finish options.

2. CNC Machining

Material is removed from solid plastic blocks using computer-controlled tools to create precise machined plastic parts. Ideal for prototypes, low-volume production, and complex geometries. Provides high accuracy and supports specialty plastics.

3. Surface Treatment

We offer precision surface treatments for plastic parts, including polishing, coating, texturing, and others, to enhance appearance, durability, and functionality. This process reduces surface defects, improves assembly consistency, and ensures plastic components perform reliably.

4. Assembly Services

Plastic components are professionally assembled through fitting, bonding, and integration with other parts. Suitable for multi-part products, electronic housings, and medical devices, this service delivers precise alignment, reliable operation, and ready-to-use parts.

Start Your Plastic Manufacturing Project!

Material Options for Plastic Products Manufacturing

The properties and processing requirements of plastic materials vary. We can provide you with the most suitable material options based on your application needs for plastic products and your budget.

- ABS

- PC

- PP

- POM

- PE

- PS

- PVC

- PTFE

- PA

- PMMA

- PU

Manufacturing Plastic Products Application

Our plastic manufacturing services support a wide variety of industries, including:

- Medical Devices: Precision and compliance for healthcare applications

- Automotive & EV: Durable, lightweight, and heat-resistant components

- Electronics & Consumer Goods: Functional parts and aesthetic housings

- Aerospace & Defense: High-performance, certified materials for critical applications

- Industrial Equipment & Energy: Reliable parts for demanding environments

Quality Assurance

With years of experience in plastic manufacturing and a proven track record across multiple industries, Jiangzhi delivers reliable, high-quality components that meet international standards. Our quality management system is ISO 9001 certified, and we employ advanced inspection equipment and certified processes to ensure every part is precise, consistent, and fully traceable.

Why Choose Jiangzhi as Your Plastic Manufacturing Partner?

High Precision & Consistent Quality

Fast Turnaround & Flexible Capacity

Expert Engineering Support

One-Stop Prototyping & Small-Batch Solution