Injection Rubber Molding Service

Jiangzhi, as a rubber molding company, delivers expert-level rubber injection molding processes, ensuring the manufacture of durable and precise custom rubber parts. Experience top-quality injection mold rubber solutions with advanced technology.

Jiangzhi specializes in injection rubber molding, catering to both low-volume production and end-use manufacturing. Our high-quality molds, typically crafted from steel, ensure exceptional durability. Starting at just $500, our mold costs are highly competitive. We offer a diverse range of rubber materials, ensuring you can choose the perfect rubber compound for your injection molding rubber project, whether it’s for prototype development or large-scale production.

What Is Injection Rubber Molding?

Rubber injection molding is a manufacturing process where rubber is injected into a custom mold under high pressure, then heated to cure and harden into the desired shape. This method produces precise, durable, and complex rubber parts, suitable for any production volume. Injection rubber molding offers design flexibility, supports a wide range of rubber materials, and ensures efficient production. It’s commonly used for seals, gaskets, and other custom rubber components across automotive, medical, and consumer goods industries.

Injection Mold Rubber Capabilities

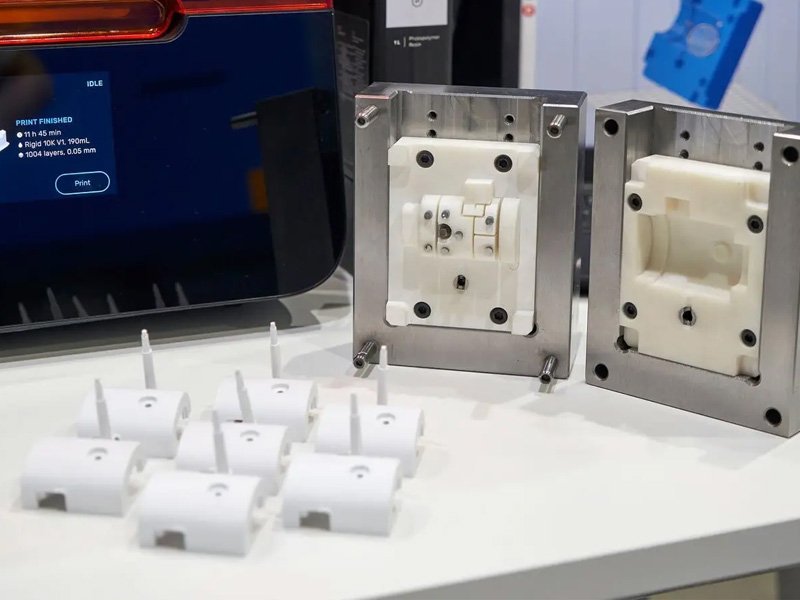

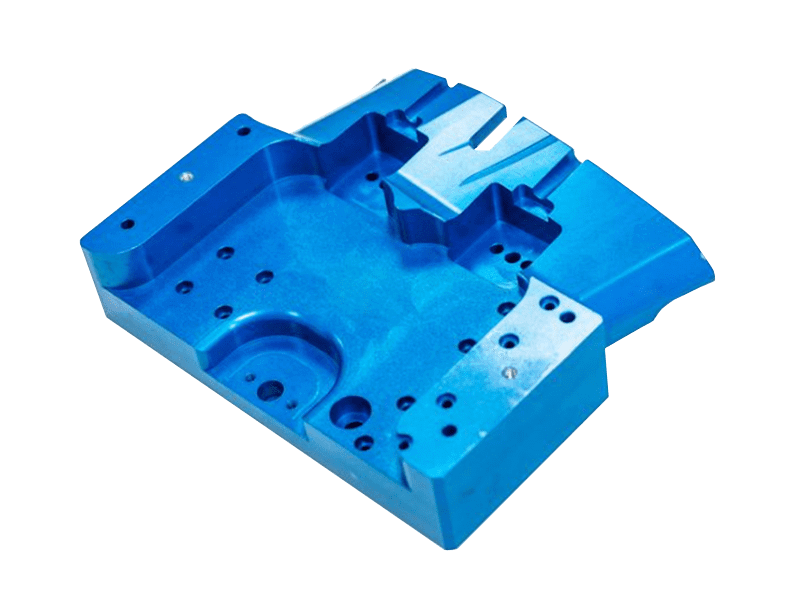

To ensure high-quality results in injection rubber molding, mastering core capabilities in rubber mold making is crucial. This involves precise injection mold design, material selection, and mold fabrication, which are key to rubber part manufacturing. These capabilities improve product quality, manufacturing efficiency, and ensure molds meet design specifications for optimal performance.

| Name | Detail |

|---|---|

| Size |

78.74in. x 59.05in. x 39.37in. 2000mm x 1500mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

Injection Rubber Molding Material

We offer a wide selection of rubber materials for injection molding, tailored to meet the specific needs of various industries. Our range includes standard rubber, medical-grade rubber, and optical-grade rubber, with hardness options ranging from Shore A 15 to 95. Our rubber materials include:

Rubber Materials

- Silicone

- Ethylene Propylene Diene Monomer (EPDM)

- Nitrile (NBR)

- Neoprene (CR)

- Styrene Butadiene Rubber (SBR)

- Natural Rubber (NR)

- Butyl Rubber (IIR)

- Fluoroelastomer(FKM)

Additives

- Softeners

- Colorants

- UV Stabilizers

- Flame Retardants

- Lubricants

- Reinforcing Agents

Rubber Materials Selection Guide

The material impacts the product's durability, performance, aesthetics, and cost. Choosing the right material for rubber molding parts is critical to the success of any manufactureing project. Read this comprehensive guide and understand the complex process of material selection.

Custom Rubber Molding Surface Finishing

We offer a variety of surface treatments for molded rubber components, including smooth, glossy, textured, and matte finishes. Our standard option is SPI finishing, with VDI finishes also available upon request, allowing you to choose the perfect surface texture to meet your rubber mold design or custom rubber parts specifications and functional requirements. These treatments not only enhance the appearance but also improve the performance and longevity of your rubber components.

| Finish | Description |

|---|---|

| SPI A1 | 6000 grit diamond, surper high glossy finish |

| SPI A2 | 3000 grit diamond, high glossy finish |

| SPI A3 | 1200 grit diamond, normal glossy finish |

| SPI B1 | 600 grit paper, fine semi-glossy finish |

| SPI B2 | 400 grit paper, normal semi-glossy finish |

| SPI B3 | 320 grit paper, normal semi- |

| SPI C1 | 600 grit stone, fine matte finish |

| SPI C2 | 400 grit stone, medium matte finish |

| SPI C3 | 320 grit stone, normal matte finish |

| SPI D1 | Dry blast glass bead, satin textured finish |

| SPI D2 | Dry blast, dull textured finish |

| SPI D3 | Dry blast, rough textured finish |

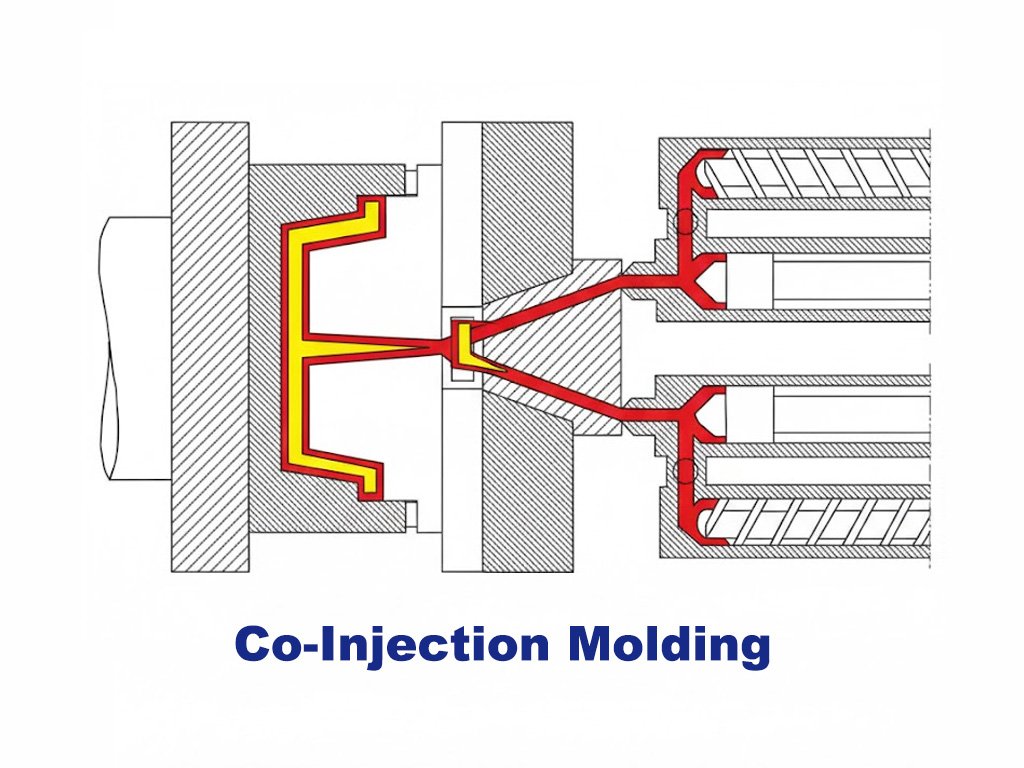

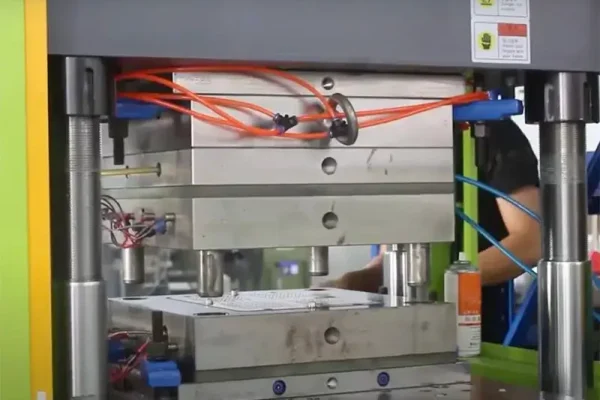

How Does Rubber Injection Molding Work?

Our injection rubber molding service process is a highly efficient method for producing a wide range of rubber parts. The rubber molding process involves several key steps:

01

Material Preparation

Rubber (e.g., EPDM, Nitrile, Silicone) is loaded and heated to make it flowable for molding.

02

Injection Molding

The rubber is injected under high pressure into the custom mold, filling all cavities and forming the part.

03

Curing or Vulcanization

Heat is applied to cross-link the rubber, giving strength, elasticity, and durability.

04

Cooling and Ejection(Demolding)

The mold is cooled, opened, and the finished part is removed and trimmed.

Examples of Rubber Injection Molding Products

Custom Contract Manufacturing Capability

Jiangzhi offers custom contract manufacturing to provide precise solutions for your business needs. Utilizing advanced technology and a flexible approach, we deliver high-quality, cost-effective production. For low or high volume, we partner with you to ensure products meet all specifications and are delivered on time.

Advantages of Injection Molding Rubber

- High accuracy and consistency

- Improve production efficiency

- High material utilization

- Adapt to complex design

- Reduced labor costs

- Reduced post-processing requirements:

Rubber Mold Injection Application

- Seals

- Gaskets and washers

- Rubber buttons

- Belts

- Bottle stoppers

- Automotive cushions

- Rubber hoses

Rubber Molding Parts in Different Industries

From O-rings and gaskets to vibration dampeners, cable boots, and hydraulic seals, rubber injection molding delivers precise, durable injection rubber components that withstand harsh operating conditions and keep machinery running reliably regardless of industry. We match material properties and geometry to your specific demands to ensure peak performance in every application.

Why Choose Us for Injection Rubber Molding Service?

High Precision & Consistent Quality

We use premium-grade steel molds and tightly controlled processes to ensure consistent, high-quality parts across each batch.

Fast Turnaround & Flexible Capacity

In-house tooling and agile workflows enable us to deliver T1 prototypes in as fast as 2 weeks, and scale to meet low-volume manufacturing needs efficiently.

Expert Engineering Support

Our experienced team provides design-for-manufacturing advice, material guidance, and prototyping recommendations to ensure manufacturability and performance.

One-Stop Prototyping & Small-Batch Solution

We offer a full stack of services, from mold design and rapid injection molding to trial runs and quality inspection, streamlining your path from idea to functional parts.

One-Stop Injection Molding Solution Manufacturer

From prototyping to full-scale production, we deliver custom plastic and rubber parts with accuracy, efficiency, and minimal waste.

Jiangzhi Other Processing Services

FAQs of Custom Rubber Injection Molding

What is your typical lead time for mold and samples?

Our typical lead time is 2–4 weeks, depending on part complexity. We confirm design and material upfront to avoid delays.

Do you have a minimum order quantity (MOQ) for rubber injection molding?

Yes. Our MOQ starts from 1 pcs, making us suitable for prototyping and low-volume production.

How do you ensure rubber parts meet tight tolerances (±0.2mm) consistently?

We achieve tight tolerances through controlled mold temperature, injection pressure, and 100% first article inspection.

Can you match a specific rubber compound from an existing part I provide?

Yes. We can analyze your sample and match or optimize the rubber compound to ensure equivalent performance.

What certifications do your rubber materials hold?

We offer materials compliant with FDA, UL, RoHS, and REACH, depending on application requirements.

How do you prevent defects like flash, air traps, or incomplete filling?

Defects are minimized through proper venting design and optimized injection speed and pressure control.

Do you offer DFM feedback before mold fabrication?

Yes. We provide DFM feedback before tooling to reduce molding risks and avoid costly revisions.

What happens if the first sample doesn't meet our specifications?

We will modify the mold at no extra cost and resample until specifications are met.