Small Part Injection Molding Service

Jiangzhi’s plastic molding division supports small to medium-sized part production with over 15 presses ranging from 22 to 450 tons.

- Ultra-Precise Tolerances

- Complex and Intricate Shapes

- High-Efficiency Automated Production

- Cost-Effective with Minimal Waste

Click to View

With years of experience in precision small part injection molding, we specialize in small plastic molding, custom-producing parts ranging from a few millimeters to palm size. We provide stable, efficient, and cost-effective small plastic molding solutions tailored to your production needs.

Jiangzhi, a china injection molding supplier, molds small parts from engineering plastics with chemical resistance and high strength. We handle material choice, mold design, and production, delivering reliable components for automotive, medical, and electronics applications.

What is Small Part Injection Molding?

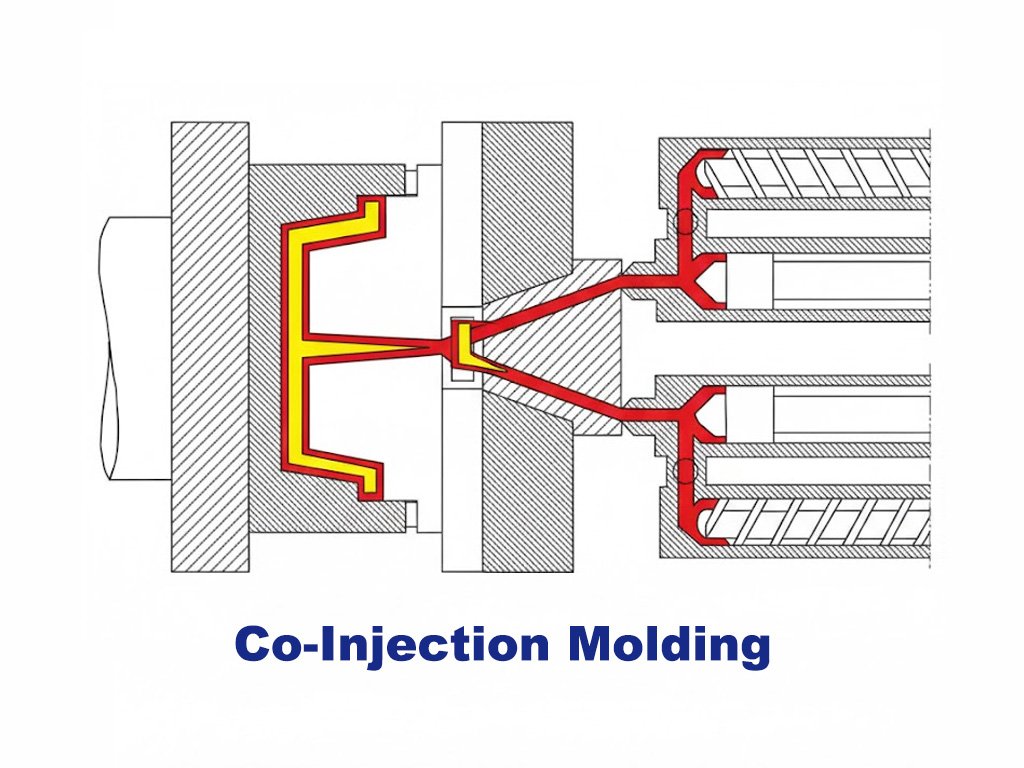

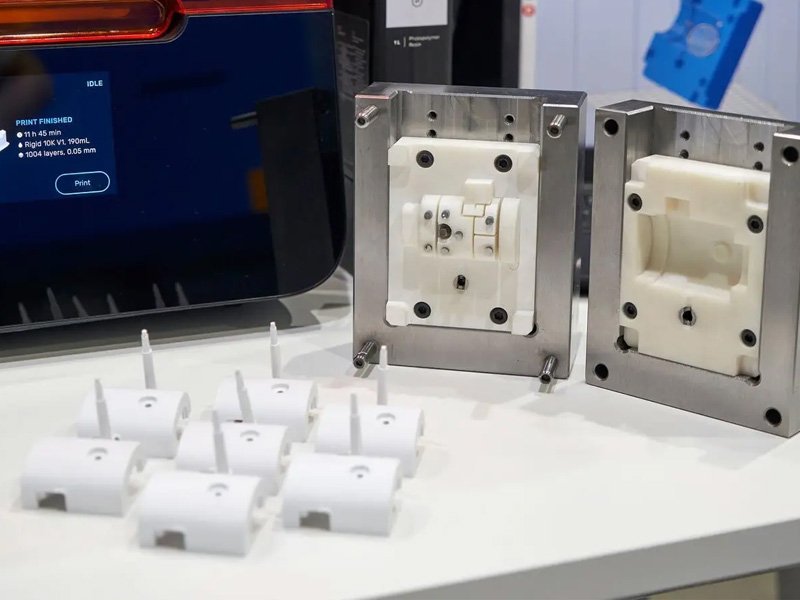

Small part injection molding is a manufacturing process used to produce precise, high-quality plastic components in compact sizes. It begins with premium plastic pellets that are carefully heated and blended into a uniform melt. Using advanced injection molding machines and custom-designed molds tooling, the molten material is injected under strict pressure control, then rapidly cooled and automatically ejected.

Request Your Small Part Injection Molding Consultation!

Advantages of Small Part Injection Molding

1. High Productivity and Scalability

Small part injection molding delivers short cycle times and consistent quality, making it easy to ramp up from small batches to mass production. High automation reduces manual work, ensuring efficiency.

2. Precision and Repeatability

Small parts usually have complex geometric shapes or fine details. Injection molding can ensure strict tolerances and produce parts that can be precisely assembled and operated.

3. Wide Material Compatibility

This molding method works with a broad selection of thermoplastics—such as ABS, polycarbonate, polypropylene, and more—offering flexibility in both part performance and application possibilities.

4. Cost Efficiency for Large Runs

Once the mold is made, each additional part can be produced at a very low cost. The larger the order, the lower the cost per part, giving significant savings for medium- and high-volume production.

Applications of Small Part Injection Molding

- Medical Devices: Used for manufacturing highly detailed, reliable components for devices such as insulin delivery pens, surgical tools, and implantable equipment.

- Electronics: Ideal for producing housings, connectors, switches, and other small components in consumer electronics and industrial equipment.

- Automotive: Supports the production of durable parts like control buttons, adjustment knobs, and other compact components that require consistent quality.

- Aerospace: Used for producing lightweight, high-strength components such as sensor housings, valve parts and small structural fittings for aircraft and spacecraft.

FAQs About Molding Small Plastic Parts

We work with a variety of engineering-grade plastics, including ABS, polycarbonate, polypropylene, nylon, and other specialized resins to meet specific performance needs.

Yes, multi-cavity molds allow us to produce several identical parts per cycle, improving efficiency and reducing per-unit costs.

Ordinary injection molding is used for larger parts with standard precision and simpler processes. Small part injection molding focuses on very small, complex parts that require higher precision, specialized molds, and stricter process control.

The selection of the appropriate TPE material needs to consider the performance requirements of the product (such as hardness, temperature resistance, elasticity, etc.), the processing process (such as the adaptation of the injection molding machine) and the environment of the end use (such as whether the anti-UV, anti-aging and other characteristics are required).