Assembly Manufacturing

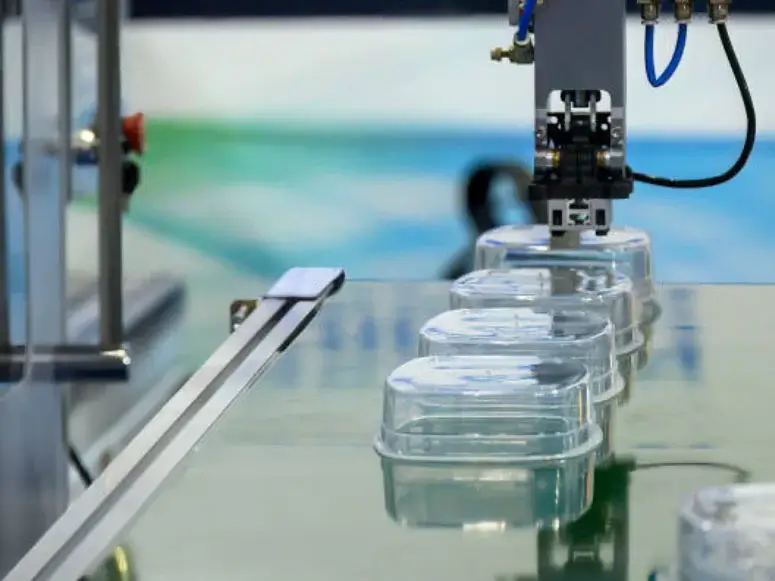

- Customized Assembly: Manual, semi-automatic, or fully automated.

- Techniques: Welding, bonding, soldering, screwing, riveting, etc.

- Quality Testing: Gasket/sealant application, air/water leak tests.

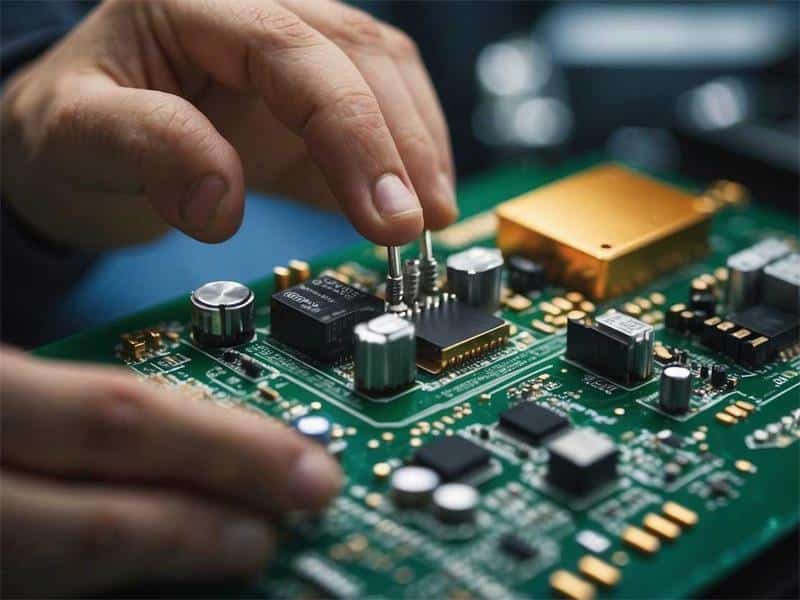

- Electronics: Installation and testing.

- Extras: Custom packaging and sourcing.

Jiangzhi Product Assembly Manufacturing

At Jiangzhi, we offer innovative contract manufacturing in China, directly from our facilities in house(plastic, rubber and metal), and do final product assembly and packing. Regard as your partner factory next to you, we assume overall responsibility for in-house manufacturing and assembly, coordinating all interfaces.We manage the entire process, from planning to functional testing. This includes procurement of purchased parts, manufacturing, assembly, and custom packaging. Support in product development, design, and optimization if needed. Our integrated capabilities not only increase efficiency but also ensure a higher level of quality assurance, as well as lower budget costs.

Our Assembly Manufacturing Capabilities

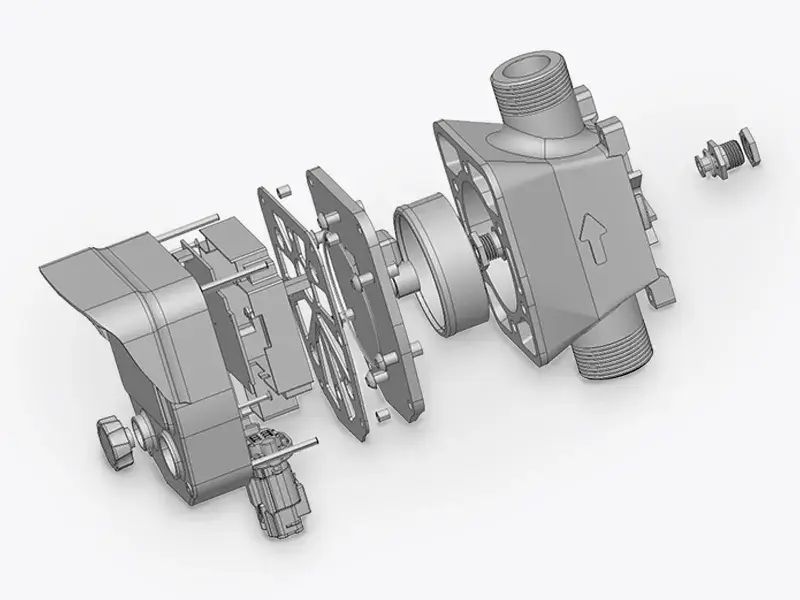

Mechanical Assembly

Electrical Assembly

Sub-Assembly Services

Custom Assembly Solutions

How to Work with Us for Assembly Manufacturing?

Submit Your Data

Project Coordination & DFM Feedback

Get Your Quote

Production & Delivery

Jiangzhi manages manufacturing with quality control, shipping parts worldwide.

Jiangzhi Contract Manufacturing Process

Manufacturing & Assembly Solutions

- Ultrasonic Welding

- Thermal Processing

- Thermal Imbedding

- Gluing

- Plug connections

- Clamp connections

- Threaded connections

- Rivet connections

- Bolt connections

- Form-Fit connections

Assembly Your Products with Jiangzhi Contract Manufacturing

Reduce Cost and Simplify Assembly

Increased Flexibility

Focus on Core Competencies

Manufacturing Expertise & Experience

Over 40+ years of expertise in delivering complex assembly projects across industries. Our leveraging experience provides you product design improvemetns, create solutions, and insights into efficient assembly methods.

Easily Scalable

IP Protection

Custom Contract Manufacturing Capability

Assembly and Manufacturing Solutions FAQs

If requested, yes. Please let us know your assembly needs during the quoting process so we can evaluate feasibility and provide an accurate cost.

In some cases, yes. We can help combine molded parts with other components you provide. Contact us with details and we’ll confirm the best solution.

Popular Post

What Is Co-Injection Molding? A Complete Beginner’s Guide

Co-injection molding is a process used in plastic manufacturing to produce parts with multiple layers of material. This method allows

Threaded Inserts for Plastic Injection Molding: Types, Methods, and Design Tips

Threaded inserts for plastic injection molding are essential in industries that require durable, reusable fasteners in plastic components. Threaded inserts

Understanding Compression Molding Products: Balancing Strength and Cost

In the world of manufacturing, how you make a product matters. Among many methods, Compression Molding is a key technique.