In modern manufacturing, the demand for high-quality, durable, and precisely engineered metal components continues to grow. Among various materials, CNC machined steel stands out as a top choice due to its versatility, strength, and reliability. In this article, we will explore the basic information and applications of CNC machined steel.

What is Steel CNC Machining?

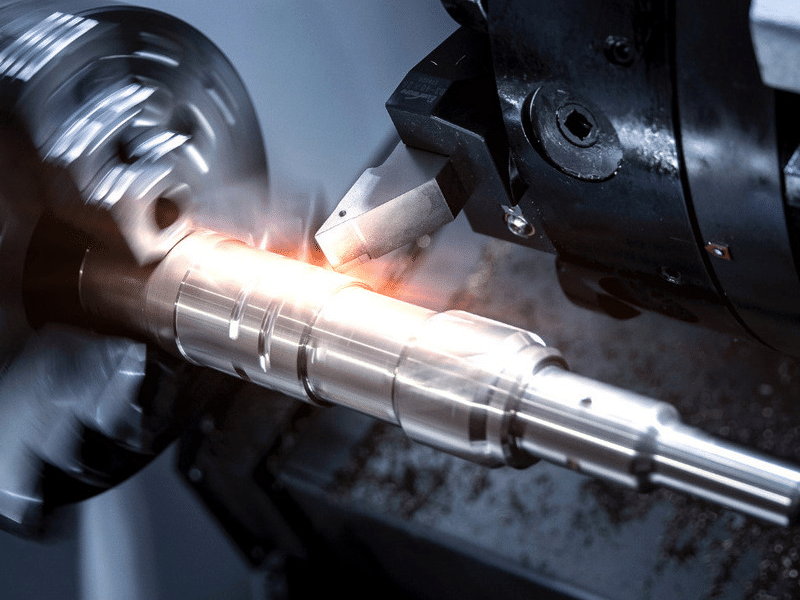

Steel CNC machining is a subtractive manufacturing process that uses computer controlled tools to carve steel into precise parts. Guided by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, CNC machines execute operations like milling, turning, and drilling, optimized for steel’s unique mechanical properties and behavior.

Types of Steel Used in CNC Machining

Different steel types offer unique properties, balancing machinability, strength, and corrosion resistance. Below is a table summarizing common steel grades used in CNC machining:

| Steel Type | Properties | Applications |

|---|---|---|

| 1018 (Low-Carbon) | Excellent machinability, moderate strength, good weldability, ductile | Gears, shafts, pins, bolts |

| 1045 (Medium-Carbon) | Balanced strength and toughness, fair machinability, good wear resistance | Crankshafts, couplings, axles |

| 1060 (High-Carbon) | High hardness, excellent wear resistance, lower machinability, brittle | Cutting blades, springs, knives |

| 4140 (Alloy) | High strength, good fatigue resistance, moderate machinability, heat-treatable | Tooling, automotive components, shafts |

| 4340 (Alloy) | Superior toughness, high strength, good ductility, challenging to machine | Aerospace components, heavy-duty gears |

| 8620 (Alloy) | Good toughness, wear resistance, case-hardening capability, fair machinability | Gears, camshafts, fasteners |

| 303 (Stainless) | Excellent machinability, good corrosion resistance, non-magnetic | Fittings, screws, bushings |

| 304 (Stainless) | High corrosion resistance, good formability, moderate machinability | Food processing equipment, piping |

| 316 (Stainless) | Superior corrosion resistance, biocompatible, good machinability | Medical devices, marine equipment |

| 17-4PH (Stainless) | High strength, corrosion resistance, heat-treatable, moderate machinability | Aerospace fittings, turbine blades |

| 410 (Stainless) | Moderate corrosion resistance, high strength, heat-treatable, fair machinability | Valves, pump shafts, cutlery |

| A2 (Tool Steel) | Exceptional hardness, wear resistance, challenging to machine, good stability | Cutting tools, dies, punches |

| D2 (Tool Steel) | High wear resistance, excellent edge retention, difficult to machine | Stamping dies, shear blades |

| O1 (Tool Steel) | Good machinability when annealed, high hardness after heat treatment | Precision tools, gauges |

| H13 (Tool Steel) | High toughness, heat resistance, moderate machinability, good thermal stability | Hot work dies, extrusion tools |

Advantages of CNC Machining Steel

CNC-machined steel offers a host of benefits, making it a go-to choice for industries demanding robust, precise components.

Material Strength and Durability: Steel’s high tensile strength ensures CNC-machined steel parts withstand heavy loads, ideal for structural and mechanical applications.

Precision and Accuracy: CNC technology achieves tight tolerances, often within microns, enabling intricate designs for complex steel components.

Cost-Effectiveness: Steel’s widespread availability and CNC automation reduce production costs, especially for high-volume runs.

Efficient Production: Automated CNC processes enable faster turnaround times and scalability from prototypes to mass production.

Versatility: CNC-machined steel supports a range of grades and applications, from automotive to medical, accommodating diverse design requirements.

Automation Efficiency: Computer-controlled processes minimize errors, ensuring consistent quality across batches of CNC-machined steel parts.

Compatibility with Finishes: Steel readily accepts surface treatments, enhancing durability and aesthetics for specific use cases.

Complex Geometries: Multi-axis CNC machines craft intricate shapes, making CNC-machined steel ideal for bespoke or high-precision parts.

Post-Processing and Surface Finishes on CNC Steel Parts

As-Machined Finish

The most basic surface right after machining, showing visible tool marks and slight imperfections, is suitable for internal parts where precise dimensions matter more than appearance.

Bead Blasted

A uniform matte finish created by blasting small glass beads at high pressure, which smooths minor surface flaws and reduces glare, ideal for aesthetic parts and improving paint adhesion.

Anodized (Type II & III Hardcoat)

An electrochemical oxide layer, where Type II offers a thinner, colored coating with moderate corrosion resistance, and Type III provides a thicker, harder layer with excellent wear and corrosion protection; mostly used on aluminum rather than steel.

Powder Coating

A durable, thick coating formed by applying dry powder and heat, offering excellent resistance to chipping and fading, commonly used for outdoor machinery, automotive parts, and components needing vibrant, long-lasting finishes.

Electroplating

A thin metal layer, such as chrome, nickel, or zinc, is deposited electrochemically to enhance corrosion resistance and aesthetics, suitable for decorative, automotive, and marine parts.

Carburizing & Nitriding

Carburizing hardens steel surfaces by introducing carbon, improving wear resistance, while nitriding introduces nitrogen at high temperatures to create a very hard, wear-resistant surface layer; both are used for gears, shafts, molds, and guides.

Passivation

A chemical treatment, typically with nitric acid, that forms a protective oxide layer on stainless steel to improve corrosion resistance, is commonly used in food and medical equipment.

CNC Machining Techniques for Steel

Producing high-quality CNC-machined steel parts requires specialized techniques to address steel’s hardness and machinability challenges. Key strategies include:

- Tool Selection: Opt for carbide or coated tools to withstand steel’s abrasiveness, reducing wear and extending tool life for CNC-machined steel components.

- Coolant Usage: Employ ample coolant or cutting fluid to reduce heat buildup and improve surface finish.

- Optimized Cutting Parameters: Adjust spindle speed and feed rates based on steel grade to balance efficiency and surface quality.

- Multi-Axis Machining: Employ 4- or 5-axis CNC machines to create complex geometries in CNC-machined steel, enhancing design flexibility.

- Workpiece Fixturing: Securely clamp the steel workpiece to minimize vibration and ensure dimensional accuracy.

- Vibration Control: Secure workpieces with robust fixturing to minimize vibrations, preserving precision in CNC-machined steel components.

- Toolpath Optimization: Use CAM software to design efficient toolpaths, reducing cycle times and improving surface finish for CNC-machined steel.

- Heat Treatment Considerations: For certain steel grades, integrating heat treatment before or after machining can improve machinability and final part properties.

Conclusion

CNC-machined steel represents the pinnacle of precision manufacturing, blending the inherent strength of steel with the accuracy of computer-controlled systems. Jiangzhi can provide CNC machining services for a wide range of steel types. Welcome to partner with Jiangzhi to bring your designs to life.