Cold slugs may seem like a minor imperfection in injection molding, but their impact on product reliability and production efficiency can be significant. As one of the common injection molding defects, cold slugs can lead to surface blemishes to internal weaknesses; This hidden defect is often hard to detect early and can affect product reliability and performance. For businesses focused on consistent quality and efficient production, understanding and eliminating cold slugs is essential.

What is a Cold Slug?

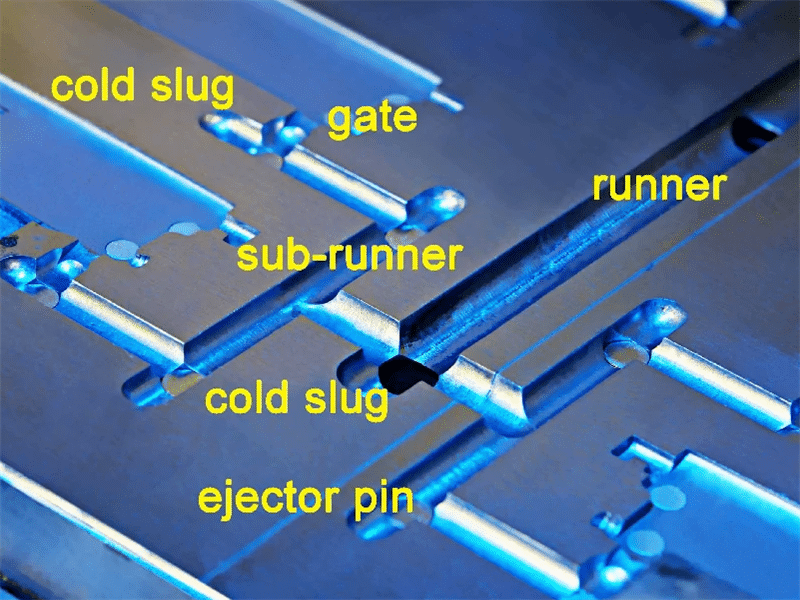

In cold slug injection molding, a cold slug refers to a small piece of plastic that solidifies before it should, typically at the nozzle tip or within the runner system. During the injection molding cycle, the nozzle, heated to 200-300°C, contacts the cooler mold, causing the plastic at the tip to lose heat and solidify. This solidified piece, or cold slug, can enter the runner system or mold cavity if not properly managed, eventually becoming embedded in the finished product. Visually, cold slugs may appear as dark spots, streaks, or blemishes on the surface of the molded part or as internal inclusions that manifest as weak points. They directly influence not only aesthetics but also mechanical properties and reliability.

Common Causes of Cold Slugs

Understanding the root causes of cold slugs is essential for effective prevention. Several factors contribute to their formation in cold slug injection molding:

Temperature Differentials

The significant temperature gradient between the injection molding machine’s barrel (typically 200-300°C) and the mold (often below 100°C) is a primary driver of cold slug formation. As molten plastic travels through the nozzle, it encounters the cooler mold surface, particularly at the sprue or gate. This rapid heat loss causes the plastic at the nozzle tip to solidify into a small, solid nub—a cold slug—before it can flow into the runner system.

For instance, if the nozzle temperature drops below the material’s melt point (e.g., 260°C for polycarbonate), the plastic begins to solidify as it lingers in the nozzle tip, forming a plug-like obstruction. This can lead to flow marks or incomplete filling in the final part, compromising both aesthetics and functionality.

Nozzle Design Flaws

Nozzles that are too long or have a large diameter increase the surface area exposed to the cooler mold, accelerating heat loss. During the injection cycle, molten plastic enters the nozzle, but if the nozzle lacks sufficient heating, the plastic cools prematurely at the tip. This cooling process, often occurring in seconds, forms a cold slug that can break off and enter the runner system during the next cycle. A poorly designed nozzle may also retain residual plastic from previous cycles, which solidifies over time, exacerbating the issue. Such slugs can cause blockages in runners, leading to short shots or inconsistent part dimensions.

Material Properties

The rheological properties of the plastic material play a critical role in cold slug formation. High-melting-point or high-viscosity materials are particularly prone to solidifying early. As these materials flow through the nozzle or runners, their poor flow characteristics cause them to lose heat quickly, especially in areas with lower shear rates (e.g., near the nozzle tip). These slugs can embed in the molded part, creating weak points that reduce structural integrity or cause visible defects like weld lines.

Mold Cooling Issues

Uneven or overly rapid mold cooling can trigger cold slugs in cold slug injection molding. Molds are designed to dissipate heat quickly to solidify the part, but if cooling channels are poorly placed or the cooling water flow is too aggressive, the plastic in the runners or near the gate may solidify prematurely. During the injection cycle, as molten plastic enters the runner system, excessive cooling can cause the material to form a solid skin along the runner walls, breaking off as cold slugs in subsequent cycles. The resulting slugs can obstruct flow, leading to incomplete parts or surface imperfections.

Suboptimal Injection Parameters

Injection parameters, such as speed, pressure, and cycle timing, directly influence cold slug formation. Slow injection speeds allow molten plastic to linger in the nozzle or runners, giving it time to lose heat and solidify. Similarly, insufficient injection pressure fails to push the plastic quickly enough through the system, allowing it to cool at critical points like the nozzle tip or runner entry. Long cycle times or extended holding phases can also cause residual plastic in the nozzle to solidify between shots. These cold slugs can then enter the mold cavity, causing defects like flow marks or compromising part strength by creating stress concentration points.

Idle Time Between Cycles

Extended idle time between injection cycles is another key factor in cold slug injection moulding. When the molding machine pauses, the plastic in the nozzle remains stationary, exposed to the cooler mold environment. Over a few minutes, this plastic cools below its melt temperature, forming a solid slug at the nozzle tip. When the next cycle begins, this slug can be injected into the runner system, potentially clogging gates or embedding in the part. Such disruptions lead to production inefficiencies, including increased scrap rates and inconsistent cycle times.

Effective Prevention Cold Slug Defect Methods

Preventing cold slugs requires a multifaceted approach. Below are proven strategies to ensure smooth, defect-free production.

Temperature Control

The nozzle and barrel should be kept slightly above the material’s melt temperature to ensure the plastic remains molten. Similarly, using mold heaters or precise cooling water flow to control mold temperatures to prevent rapid heat loss. Monitor and adjust conditions in real time through the advanced temperature control systems with sensors and feedback loops, minimizing the risk of cold slug formation.

Injection Parameters

Increasing injection speed and pressure to make the molten plastic flows quickly into the mold, reducing the time it has to cool in the nozzle or runners. Extending holding time helps prevent premature cooling. Optimize cooling time through experimentation, balancing mold temperature and cycle efficiency to avoid both cold slugs and excessive cycle times.

Material Selection

Choose materials with better flow properties. For high-melting-point materials, adding plasticizers to improve flow. Adjust processing conditions for challenging materials to ensure they remain molten throughout the injection process.

Mold Cooling

Well Design cooling systems for uniform heat dissipation, avoiding areas of rapid cooling that trigger cold slug formation. Regular maintenance cooling system and cleaning cooling lines to remove blockages, ensures optimal performance.

Cold Slug Well Design

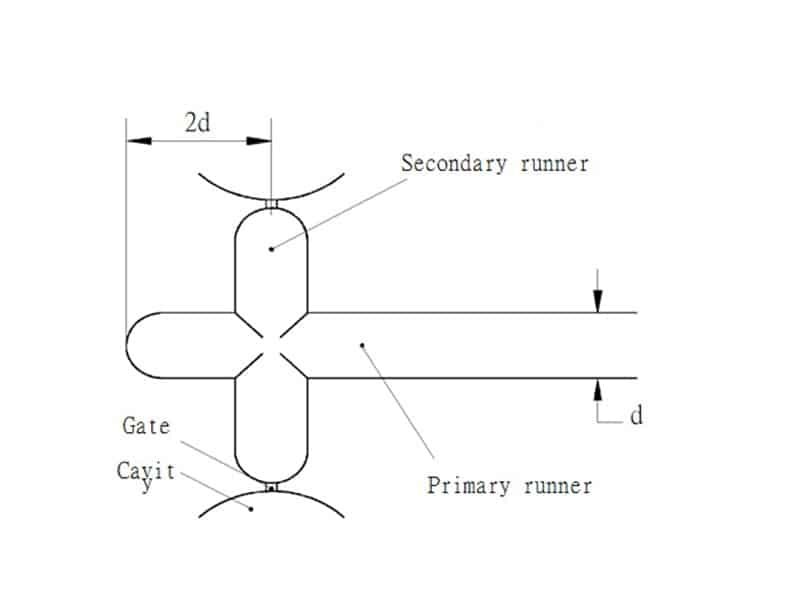

A well-designed cold slug well in injection molding trap solidified plastic before it enters the mold cavity.

- Size and Shape: Cold slug wells should be 20-30% larger than the runner width to capture slugs without causing pooling or short shots. A typical well might be 1.5-2 times the runner diameter in depth.

- Material: Use durable materials like prehardened stainless tool steels (e.g., P20 or PX5) to withstand thermal and mechanical stresses over thousands of cycles.

- Features: Incorporate reverse hooks or Z-shaped pull rods to prevent slugs from re-entering the flow. These act like a one-way gate, ensuring slugs stay trapped.

- Placement: Place the cold slug well immediately before the gate or sprue where cold chunks are most likely to form.

Conclusion

Cold slug issues in injection molding result from multiple factors including thermal, mechanical, material, and design aspects. Proactive measures focusing on temperature control, injection process optimization, material properties, uniform mold cooling, and careful design of the cold slug well can effectively reduce defects and manufacturing waste. Jiangzhi specializes in these areas to ensure improved product quality. Welcome to contact us for a custom injection molding service solutions.