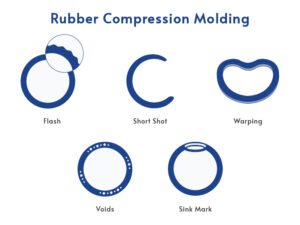

Compression molding, a cornerstone of manufacturing, transforms raw materials into precise, durable components by compressing preheated material within a heated mold. However, compression molding defects, such as short shots, flash, warpage, bubbles, voids, and sink marks, can undermine product quality, reduce production efficiency, and inflate costs. This article examines common defects in rubber compression moulding, their causes, solutions, and practical optimization strategies.

Causes and Solutions of Common Compression Molding Defects

Compression molding defects are in various forms. Below, we delve into the most prevalent rubber compression molding defects and the proven solutions.

Short Shot (Incomplete Fill)

One of the most prevalent defects in rubber compression molding is the short shot, or incomplete cavity fill. In rubber compression moulding, short shots are often caused by insufficient material volume, low compression pressure, or poor mold venting that traps air and restricts material flow. Premature curing of rubber compounds, which harden before filling the mold, can also contribute.

Solutions: Enhancing venting systems to release trapped air volatiles, adjusting material temperature to improve flowability, ensuring sufficient material charge, and simplifying flow paths can mitigate short shots. Modifying process parameters such as pressure and compression time also aids in completing the fill.

Flash

Flash, or overflow, occurs when excess material escapes the mold seams, creating thin, unwanted protrusions. This compression moulding defect is common in rubber compression molding due to the material’s flowability. Causes include excessive material, high compression pressure, or poor mold sealing from worn clamps or misaligned molds.

Solutions: Use precise material measurements to match mold capacity, minimizing excess. Adjust pressure to balance complete filling with preventing leakage. Regularly check and repair clamps and mold alignments to ensure a tight seal.

Warping

Injection molding warping is the deformation or distortion of parts after molding, causing dimensional inaccuracies and surface imperfections. Uneven cooling rates across the molded part, residual stresses from molding pressures, and inconsistent material thickness cause warping. In rubber compression moulding, warpage is exacerbated by rubber’s high elasticity and sensitivity to thermal gradients.

Solutions: Uniform and controlled cooling through improved mold thermal design, balanced part thickness, and optimized pressure application during the compression process help prevent warpage. Adjusting mold design and gating may also reduce material stress.

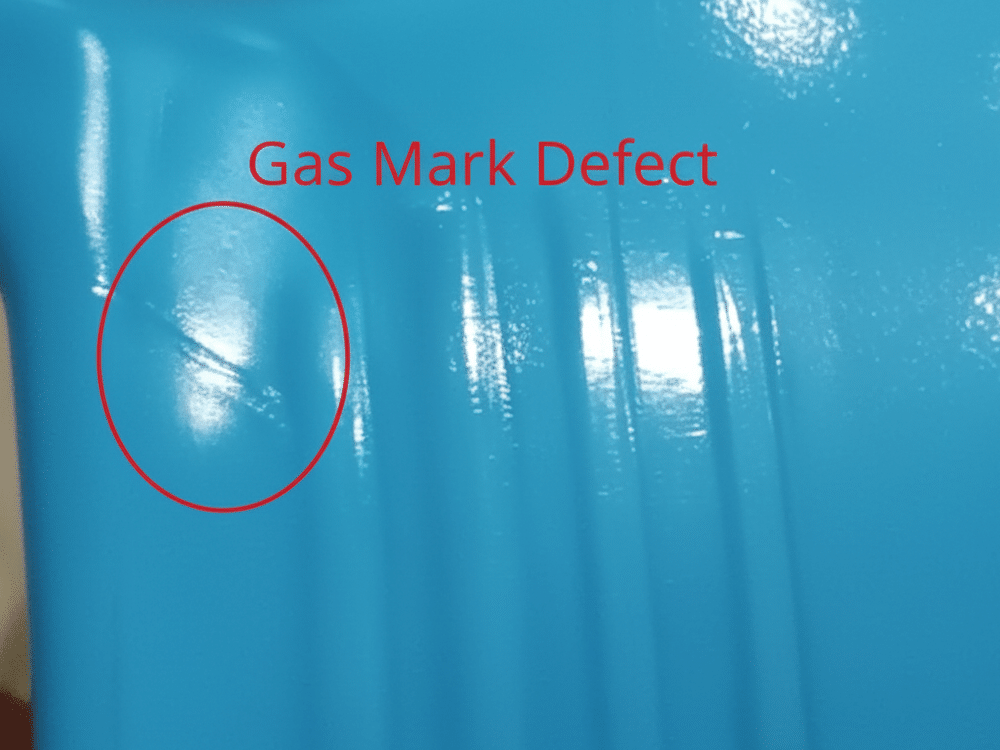

Bubbles and Voids

Trapped air or gases form voids or bubbles within molded parts, leading to weak spots and compromised mechanical properties. These rubber compression molding defects arise from poor mold venting, high moisture content in rubber compounds, or excessive compression speed that traps gases.

Solutions: Improve Mold Venting: Add vents or optimize their placement to allow air and gases to escape during compression. Thoroughly dry rubber compounds to remove moisture, which can vaporize and form bubbles. Slow the compression process to give gases time to escape, especially for high-viscosity rubbers.

Sink Marks

Sink marks, surface depressions caused by uneven cooling or material shrinkage, are a common compression moulding defect. In rubber compression molding, thick sections or insufficient cooling time exacerbate this issue due to the rubber’s thermal properties.

Solutions: Use thinner, uniform walls or add ribs to reduce material volume in thick areas. Allow sufficient time for even solidification to minimize surface depressions. Choose rubber compounds with stable thermal properties to reduce shrinkage.

Practical Tips for Optimizing Compression Molding

Optimizing compression molding extends beyond defect management to incorporate improvements in mold design, materials, process parameters, and equipment maintenance.

Mold Design

Employ precise mold machining and finishing techniques to guarantee tight tolerances and smooth surfaces. Integrate adequate venting systems positioned to effectively evacuate gases during compression. Balance mold temperature distribution and strategically place cooling channels to maintain consistent temperatures for uniform heating and cooling.

Material Selection

Use high-quality rubber compounds or thermosetting resins suitable for compression molding. Adjust elastomer fillers properly to enhance desired physical properties without compromising quality. Precondition materials to remove moisture and contaminants.

Process Parameter Control

Maintain accurate temperature controls on molds and materials to promote optimal flow and curing. Maintaining consistent mold and material temperatures, adjusting optimal compression pressure, and precise cycle times to avoid defects while maintaining efficiency. Fine-tune pressure, compression time, and cooling cycles to match material characteristics. Utilize mold flow simulation software to anticipate and mitigate issues.

Regular Maintenance

Regularly inspect and service molds and molding presses to prevent wear-related defects like flash or incomplete filling. Train operators in best practices, defect recognition, and equipment handling.

Partnering with Jingzhi for Professional Compression Molding

Choosing a trusted partner for rubber compression molding defects prevention is essential to achieve high-quality, defect-free parts. Jiangzhi supplies professional rubber compression molding services, leveraging advanced equipment and extensive industry experience to minimize compression molding defects.