What Are Countersink Holes?

Countersink holes are conical recesses machined or formed at the opening of a drilled hole. Their primary function is to allow a countersunk fastener, typically a flat-head screw or rivet, to sit flush with or slightly below the surface of a part. This flush fit reduces protrusions, improves assembly clearance, and creates a consistent surface finish.

Countersink holes are defined not only by diameter but also by angle. The geometry of the countersink must closely match the angle of the fastener head to ensure proper contact and load distribution. When designed correctly, the fastener head engages evenly with the conical surface, minimizing localized stress and improving joint stability.

Fundamentals of Countersink Holes

The defining feature of a countersink hole is its tapered, conical profile. This geometry transitions from the larger opening diameter down to the nominal hole diameter. During assembly, the fastener head slides into the tapered section until it contacts the conical surface, stopping at a depth determined by the angle and diameter of the countersink.

The working principle relies on angle matching. If the fastener head angle and the countersink angle are aligned, the contact surface is evenly distributed around the circumference. When they are mismatched, contact becomes uneven, which can lead to poor seating, deformation, or loosening over time.

Common Standard Angles

Standard countersink angles are well defined in fastener and machining standards.

- 82°: predominant in ANSI and imperial systems (common in North America).

- 90°: standard in ISO and metric systems (widely used globally).

- 100°: frequently specified for aerospace rivets and thin-sheet applications.

- Other angles, such as 120°, appear in specialized fasteners.

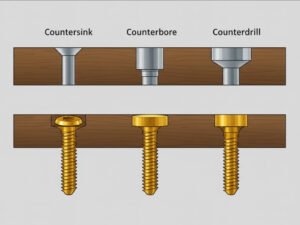

Countersink vs. Counterbore

Countersink holes are often compared with counterbore holes. The key differences are summarized below:

| Feature | Countersink Hole | Counterbore Hole |

|---|---|---|

| Shape | Conical taper | Cylindrical flat-bottom recess |

| Fastener type | Flat-head screws, flat-head rivets | Socket-head, button-head, or hex bolts |

| Surface result | Head flush or slightly below surface | Head fully recessed, surface flat |

| Typical use | Appearance-critical, thin materials | Applications requiring maximum recess |

| Machining complexity | Generally simpler | Requires additional flat-bottom operation |

Manufacturing Methods for Countersink Holes

Countersink holes can be produced using several manufacturing approaches, depending on material, tolerance requirements, and production volume.

CNC Machining

Computer-controlled milling or drilling centers produce the most accurate countersink holes. Separate tools or programmed toolpaths allow precise control of angle, diameter, and depth. This is the preferred method for metals, composites, and high-precision parts.

Manual and Semi-Automated Machining

In lower-volume production or prototyping, countersinking a hole may be performed using drill presses or handheld tools. While this approach is flexible, it is more sensitive to operator technique and tool condition, which can affect surface finish and dimensional consistency.

Drill and Countersink Combination Tools

A single tool drills the pilot hole and forms the cone in one operation. This method is efficient for manual or small-batch production in wood, plastic, and softer metals.

Sheet Metal Forming

In sheet metal, countersink holes are often created by pressing a tapered punch into the material. This displaces rather than removes material, producing consistent results with low tooling cost.

PCB Fabrication

Printed circuit boards use controlled-depth milling or specialized drills to create countersink holes. The process must be carefully managed to avoid damaging internal layers.

Advantages and Value of Countersink Holes

The use of countersink holes provides several practical advantages in engineering and manufacturing.

- From a functional standpoint, countersink holes allow fasteners to sit flush with the surface, reducing interference with moving parts or mating components.

- From a structural perspective, proper countersinking improves load distribution between the fastener and the part. When the contact surface is uniform, the joint is less prone to loosening or localized deformation.

- Countersink holes also contribute to safety and usability. Flush-mounted fasteners reduce sharp edges and minimize the risk of snagging or abrasion during handling or operation.

- Finally, in products where appearance matters, countersink holes provide a cleaner and more uniform surface without raised fastener heads.

Common Application Scenarios

Countersink holes appear across many industries:

Aerospace: used on aircraft skins and structural assemblies.

Automotive: interior trim panels, engine covers, and exterior components.

Electronics: enclosures, laptop chassis, and PCB mounting points.

Furniture and woodworking: wood screws.

Industrial machinery: moving parts and safety guards.

Design and Engineering Guidelines

Proper design of countersink holes requires attention to several factors:

Angle matching: always select a countersink angle that matches the fastener head exactly.

Diameter clearance: the top diameter of the countersink should be 0.2–0.5 mm larger than the fastener head to account for tolerances and plating.

Depth control: the cone depth should allow the head to sit flush or 0.1–0.2 mm below the surface. Excessive depth weakens the surrounding material.

Edge distance: Maintain sufficient material between the countersink and the part edge to prevent cracking, especially in thin sheets.

Tolerance and specification: Use CAD built-in countersink features when possible. On drawings, specify as: ⌵ Ø 8.5 × 90° × depth 2.5 mm.

Material considerations: softer materials may require slightly larger clearances to prevent galling during installation.

Conclusion

When properly designed for injection molding, countersink holes, as a specific type of hole used in plastic parts, improve assembly efficiency, reduce secondary operations, and enhance the overall durability and appearance of plastic parts. For future projects, applying injection-molding-specific design guidelines for countersink holes will help ensure consistent quality, reliable fastening, and optimized production costs.

FAQ

The depth is determined so the flat-head screw sits flush with or slightly below the surface. It is calculated based on the screw head diameter, head height, and countersink angle (commonly 82° or 90°). Use the formula: depth = (major diameter - minor diameter) / (2 × tan(angle/2)), or reference fastener specifications. In sheet metal, limit depth to no more than 60% of material thickness to maintain strength.

Loosening or damage occurs if the countersink angle does not match the screw head, creating poor contact and uneven load.

Use a proper countersink tool aligned to the drilled hole, with controlled speed, feed, and depth stop. Check the final countersink diameter, angle, and head flushness with the real fastener, and define clear dimensions and tolerances on the drawing to guide machining and inspection.

Metals (steel, aluminum, stainless steel), plastics, wood, and PCB laminates can all use countersink holes if the depth is chosen to leave enough residual thickness.