Ejector marks are a pervasive and often unavoidable feature in injection molding that can significantly affect the final product’s appearance, functionality, and durability. As one of the common injection molding defects, they require careful design and process control to minimize their impact. Want to eliminate unsightly or damaging ejector marks in molded parts? This article breaks down everything you need to know, from root causes to reliable prevention techniques.

What Are Ejector Marks?

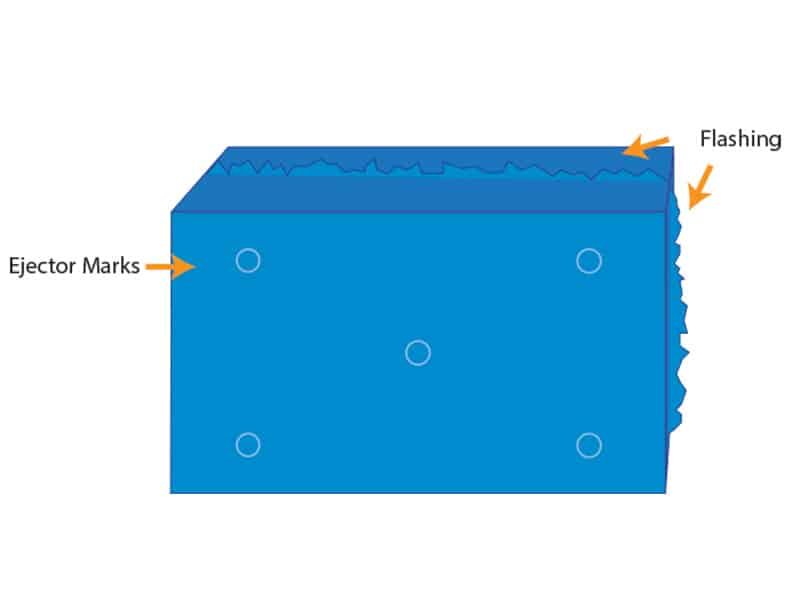

Ejector pin mark are surface defects that occur when ejector pins apply force to release the molded part from the mold cavity. They are typically occurring at the locations where ejector pins contact the product. These marks may appear as small indentations, depressions, glossy or white imprints, or sometimes as dimples or shadowed areas without any pronounced raised or sunken features.

Identifying Ejector Pin Marks

Most ejector pin marks in injection molding can be identified through visual or tactile inspection. Look for small depressions, raised bumps, or whitish stress marks near the locations where ejector pins contact the part. These marks are often more pronounced on glossy or thin-walled parts, where even minor imperfections stand out.

For more precise identification, advanced techniques like surface profilometry or 3D scanning can quantify the depth and severity of ejector pin marks. These methods are particularly useful in high-precision industries, such as medical device manufacturing, where even microscopic ejector marks can affect performance. By running a finger across the surface or using a magnifying lens, we can confirm the presence of pin marks in injection molding and assess their impact.

Impact of Ejector Pin Marks on Product Quality

The presence of ejector pin marks in injection molding can affect the quality of molded parts.

Aesthetic Impact

Ejector marks disrupt the uniformity and smoothness of the product surface, which can reduce the visual appeal of consumer products or precision plastic components. Glossy or whitish impressions may contrast starkly with the intended finish, making parts look defective.

Functional Impact

Beyond appearance, ejector pin marks can impair the function of molded parts. When marks occur on critical surfaces—such as sealing faces, mating parts, or precision-fit interfaces—they may cause gaps, leaks, or improper assembly.

Structural Reliability

Ejector marks indicate localized stress points caused by the mechanical force of pins pushing the molded part out of the cavity. These concentrations of stress can weaken the material at the contact zones, creating potential initiation sites for cracks or fractures during service or handling.

Common Causes of Ejector Pin Marks

Several factors contribute to the formation of ejector pin marks in injection molding, spanning design, process, and material considerations. A well-designed ejection system plays a crucial role in minimizing these marks by ensuring smooth and uniform part release during demolding.

Ejector Pin Design

The design of the ejector pins themselves is a primary culprit. If the pins are too small, too few, or poorly placed, they may exert uneven or excessive force, leading to ejector pin marks. For instance, placing pins in areas with thin walls or complex geometries can amplify stress, resulting in visible ejector marks. Similarly, using pins with sharp edges or inadequate surface finish can increase the likelihood of defects.

Demolding Parameters

Excessive ejection force, premature ejection before the part has fully cooled, or insufficient cooling time can all contribute to ejector pin marks in injection molding. For example, if the part is ejected while still partially molten, the pins may deform the surface, leaving noticeable pin marks in injection molding.

Product Structure Design

The design of the molded part plays a significant role. Parts with uneven wall thickness, insufficient draft angles (typically less than 1-2°), or abrupt transitions from thick to thin sections are prone to ejector marks. These design flaws can cause the part to stick to the mold, requiring greater ejection force and increasing the risk of ejector pin marks.

Mold Surface

The condition of the mold surface is critical. A mold with poor surface finish—say, a roughness value exceeding Ra0.05—can cause the part to adhere, necessitating higher ejection forces and leading to ejector marks injection molding. Inadequate mold coatings or lack of release agents can exacerbate this issue, as the part clings to the mold cavity during demolding.

Injection Molding Process

Finally, the injection molding process itself can contribute to ejector pin marks. Low mold temperatures, high injection pressures, or improper material preparation (e.g., insufficient drying of hygroscopic resins) can result in uneven cooling or material flow, increasing the likelihood of defects.

Solutions and Prevention Strategies

Ejector marks injection molding can be mitigated through a combination of strategies.

Optimize Ejector Pin Design

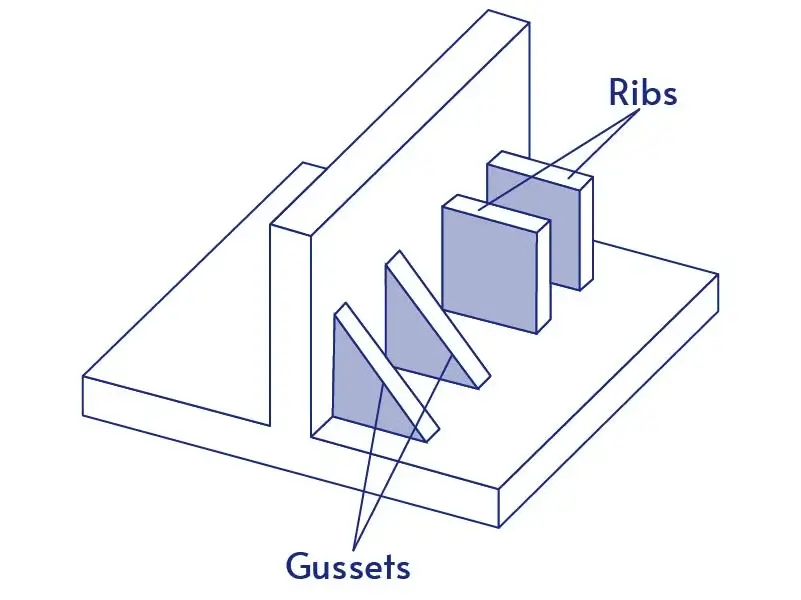

- Increase Pin Count: Distribute ejection force more evenly by using multiple pins, especially for larger or complex parts.

- Adjust Pin Size and Shape: Use appropriately sized pins with rounded edges to minimize stress concentration.

- Strategic Placement: Position pins in non-critical or less visible areas, such as ribs or hidden surfaces, to reduce the visibility of ejector pin marks.

Refine Demolding Parameters

- Reduce Ejection Force: Calibrate the ejection mechanism to apply the minimum force necessary to release the part.

- Optimize Timing: Ensure the part has cooled sufficiently before ejection to prevent deformation.

- Extend Cooling Time: Allow adequate cooling to ensure the part is rigid enough to withstand ejection forces without forming ejector marks.

Improve Product Design

- Incorporate Draft Angles: Add draft angles of 1-2° to facilitate smooth demolding and reduce sticking.

- Ensure Uniform Wall Thickness: Design parts with consistent wall thickness to promote even cooling and minimize stress.

- Simplify Geometries: Avoid sharp transitions or complex features that increase the risk of ejector pin marks in injection molding.

Enhance Mold Surface

- Polish Mold Surfaces: Achieve a mirror-like finish (Ra0.05 or better) to reduce friction and part sticking.

- Apply Release Coatings: Use mold release agents or coatings, such as PTFE, to ease demolding and prevent ejector marks.

- Regular Maintenance: Routinely inspect and polish molds to maintain optimal surface conditions.

Optimize Injection Molding Process

- Increase Mold Temperature: Raise the mold temperature to promote uniform cooling and reduce internal stresses.

- Adjust Injection Speed and Pressure: Fine-tune these parameters to ensure smooth material flow and minimize defects.

- Proper Material Preparation: Dry hygroscopic materials thoroughly to prevent moisture-related issues that exacerbate ejector pin marks.

Conclusion

Ejector pin marks are a common but manageable issue in injection molding that affect aesthetics, functionality, and structural integrity. By understanding their causes and applying targeted plastic parts design and process improvements, these defects can be significantly reduced to enhance product quality. Jiangzhi offers expert guidance and tailored solutions to minimize ejector marks