Brittleness is a key material property that directly affects performance and reliability in injection molding. Understanding how brittleness manifests during molding and in end-use conditions is essential for making informed material choices and ensuring product quality. In the context of a professional injection molding service, addressing brittleness early in the design and material selection stage helps reduce failures and improve long-term durability.

What Is Brittleness?

Brittleness is defined as the characteristic of a material wherein it fractures or breaks without undergoing significant plastic deformation. That is, it lacks the ability to bend or stretch appreciably before snapping. In simpler terms, brittle materials break suddenly and sharply, rather than bending or warping under pressure. Different with ductile materials, brittle materials absorb very little energy before fracturing.

Examples of Brittleness Objects and When Does Brittleness Occurs

- Ceramics: These are inorganic non-metallic materials such as porcelain, brick, and technical ceramics. They have high hardness and wear resistance but fracture easily without plastic deformation due to their ionic bonding and limited slip systems.

- Glass: Known for its transparency and hardness, glass is brittle and prone to sudden fracture under impact.

- Concrete and Stone: Common construction materials like concrete and natural stone are brittle and fail without significant plastic deformation.

- Cast Iron: Both gray and white cast irons exhibit brittle behavior, especially under tensile stress.

- Graphite: Another example of a brittle material with low ductility.

- Certain Metals and Alloys: Some metals, particularly those with body-centered cubic (BCC) or hexagonal close-packed (HCP) crystal structures, can be brittle, especially at low temperatures or under specific heat treatments.

- Polymers (under certain conditions): Some plastics and polymers become brittle due to environmental factors, temperature changes, or chemical degradation.

- Composite Materials: Fiber-reinforced composites or fiber-cement materials can be quasi-brittle, showing brittle fracture characteristics with limited plasticity.

Why Do Materials Turn Brittle?

Material Composition: Brittleness often arises from a material’s atomic or molecular structure. Materials with strong ionic or covalent bonds lead to fracture.

Environmental Factors: Low temperatures can cause brittleness, especially in metals and plastics. For example, steel undergoes a ductile-to-brittle transition at low temperatures, and plastics like polystyrene become “plastic brittle” in cold conditions due to stiffened molecular chains.

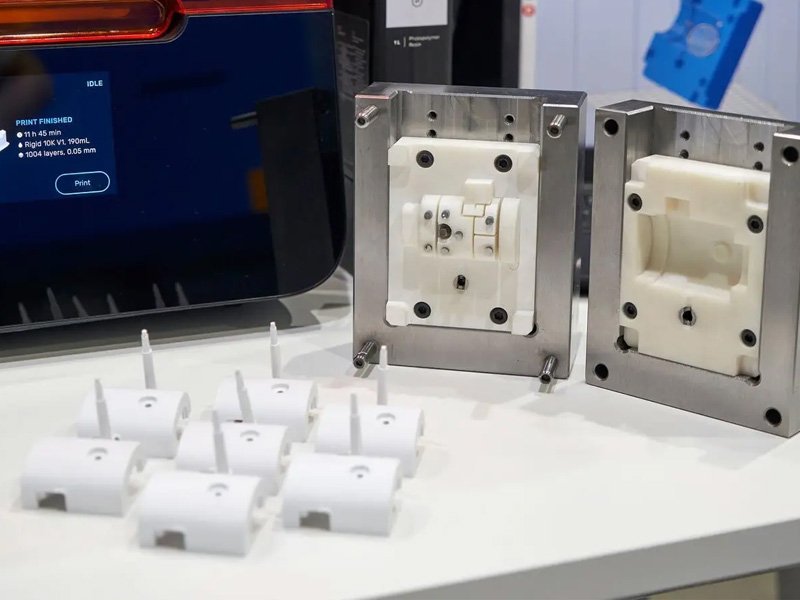

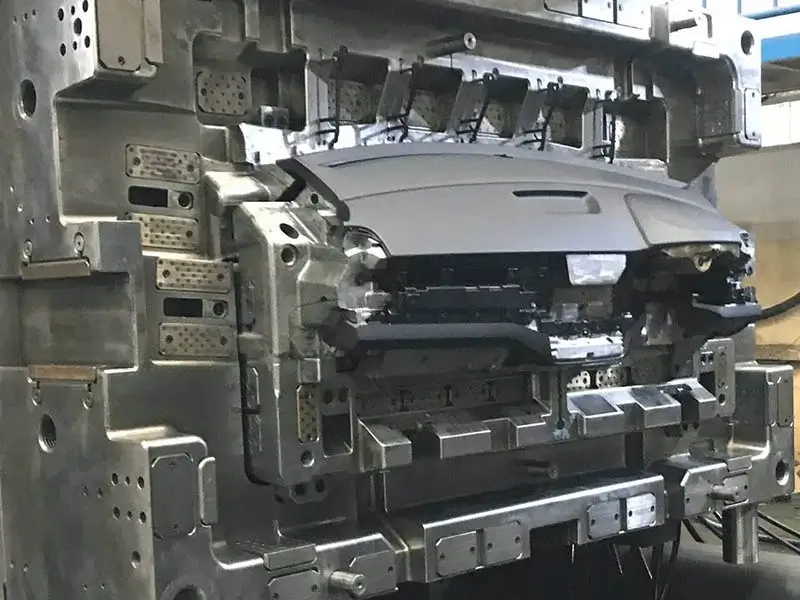

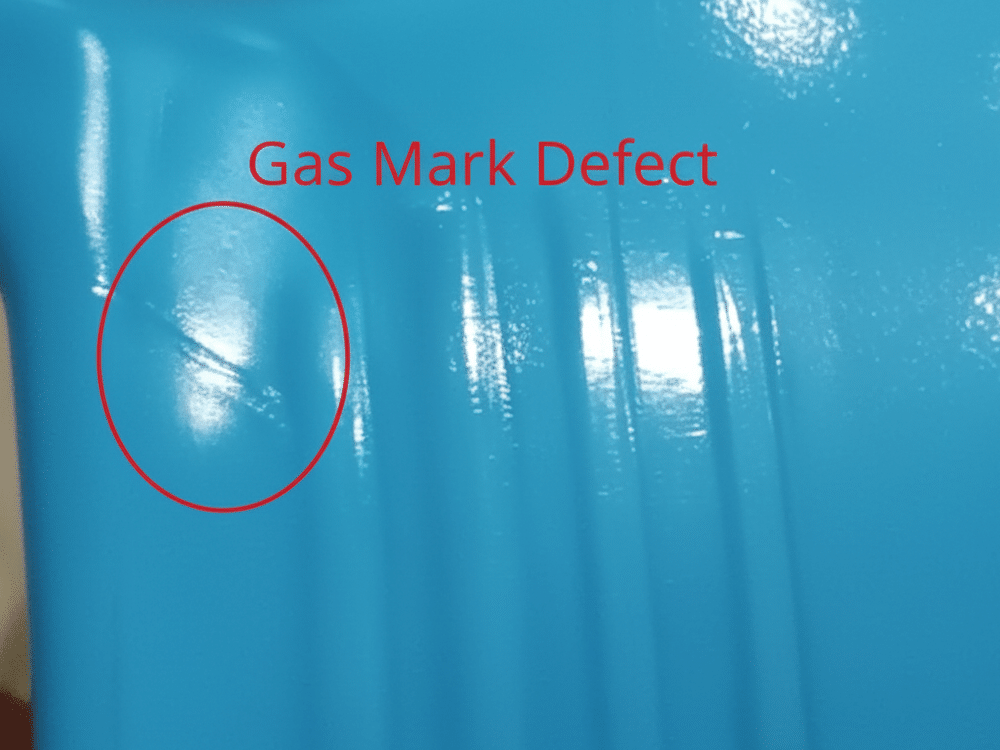

Processing Flaws: Manufacturing processes like rapid cooling or improper heat treatment can introduce internal stresses or defects (e.g., microcracks, impurities), increasing brittleness.

External Degradation: Prolonged exposure to UV light, chemicals, or moisture can degrade materials, particularly plastics, making them brittle.

Mechanical Factors: High strain rates (e.g., sudden impacts) or cyclic loading (fatigue) can induce brittleness, especially in materials with inherent flaws.

Considerations When Working with Brittle Materials

When working with brittle materials, taking special precautions to maximize their effectiveness and durability is essential.

Design Implications: Engineers often need to add reinforcements to enhance a brittle material’s performance under stress. Designs should minimize tensile loads on brittle components to avoid failure.

Handling and Safety: Brittle materials can fracture easily during handling and machining. Proper safety measures, such as protective gear and careful handling, are necessary to avoid breakage and ensure worker safety.

Alternatives to Brittle Materials: If the application requires resilience to impact or vibration, ductile materials may be more practical in some cases.

Understanding the limitations of brittle materials allows manufacturers to make informed choices about when to use them and when to seek alternatives.

Conclusion

Brittleness is not inherently a flaw but a material trait that must be understood and managed within the context of injection molding. Based on our experience, we’ve found that aligning material selection with product requirements, fine-tuning processing parameters, and anticipating environmental stressors are key to preventing brittleness-related failures. By understanding how brittle materials behave, we help our customers achieve stronger, longer-lasting molded parts tailored to their applications.