When it comes to manufacturing durable, high-performance plastic parts, glass filled nylon injection molding stands out as a versatile and reliable choice. This technique combines the toughness of nylon with the reinforcing power of glass fibers, resulting in components that offer superior strength, rigidity, and thermal stability. In this article, we will explore what glass filled nylon is, its types, the role of glass fibers, the advantages and disadvantages of using this material in injection molding, its primary applications, important design considerations, and how it compares to other manufacturing methods like 3D printing and CNC machining.

What Is Glass Filled Nylon?

Glass filled nylon, also known as glass reinforced nylon, is a composite material created by blending nylon polymers with glass fibers. The glass fibers typically range from 10% to 50% by weight, with the exact percentage influencing the material’s mechanical and thermal properties. The addition of glass fibers significantly enhances the stiffness, tensile strength, and dimensional stability of the nylon base. This combination results in a plastic that is not only tougher but also better suited to withstand heat and wear compared to unfilled nylon.

The glass fibers act as a reinforcing agent, improving the overall structural integrity of the molded parts. They reduce the material’s tendency to absorb moisture—a common issue with nylon—and minimize shrinkage during cooling, which leads to improved dimensional accuracy. Glass filled nylon injection molding temperature is usually higher than that of pure nylon, reflecting the material’s enhanced heat resistance.

Advantages of Glass Filled Nylon Injection Molding

The benefits of using glass filled nylon in injection molding projects are numerous and impactful:

- Increased Mechanical Strength and Rigidity: The glass fibers boost the hardness and stiffness of nylon, making parts more durable and resistant to deformation under load.

- Improved Heat Resistance: Glass reinforced nylon injection molding enables parts to perform reliably at elevated temperatures, often with heat deflection temperatures around 235°F or higher.

- Enhanced Wear and Chemical Resistance: Components made from glass filled nylon exhibit superior resistance to abrasion and many chemicals, except for strong acids and bases.

- Greater Dimensional Stability: Reduced shrinkage and moisture absorption help maintain tight tolerances and consistent part quality.

- High Creep Resistance: The material resists deformation over time under continuous stress, which is critical for load-bearing automotive and industrial parts.

- Electrical Insulation: Glass filled nylon is electrically nonconductive, making it suitable for electrical housings and automotive components.

Disadvantages of Glass Filled Nylon Injection Molding

Despite its many benefits, glass filled nylon does have some drawbacks:

Increased Brittleness: Adding glass fibers can reduce the material’s impact resistance, making parts more prone to cracking under sudden shocks.

Higher Material and Processing Costs: The composite material is more expensive than unfilled nylon, and the abrasive nature of glass fibers accelerates mold wear, increasing tooling costs.

Processing Complexity: Injection molding glass filled plastic requires careful control of temperature and injection speed to avoid defects such as warping or poor fiber dispersion.

Mold Wear: The abrasive nature of glass fibers accelerates wear on molds, increasing maintenance costs and potentially affecting long-term production economics.

Weight Increase: The addition of glass fibers adds density, which may be a consideration in lightweighting efforts.

Potential Weld Line Weakness: The presence of glass fibers can create weak points at weld lines, requiring thoughtful part and mold design.

Applications of Glass-Filled Nylon

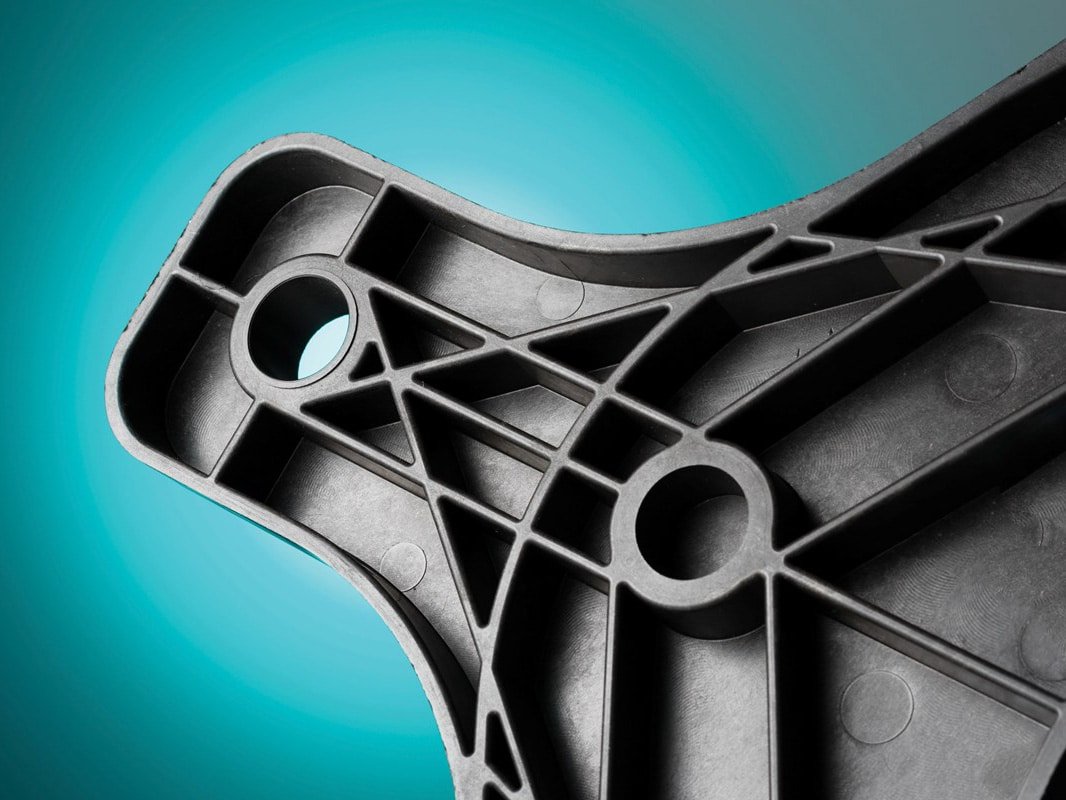

The versatility of glass-filled nylon injection molding shines across diverse industries, where its strength and precision meet real-world demands:

- Automotive: gears, brackets, and under-hood parts

- Industrial: Bearings, pump housings, and machinery components

- Consumer Goods: Power tool housings and appliance parts

- Electronics: Connectors, insulators, and enclosures

Design Considerations for Glass-Filled Nylon Injection Molding

Successful glass-filled nylon injection molding hinges on thoughtful design to mitigate challenges and maximize benefits. Key considerations include:

Uniform Wall Thickness: Maintain walls between 2–4 mm to ensure proper material flow and minimize defects like warping or sink marks.

Balancing Glass Fiber Content: Higher glass content increases stiffness but reduces toughness. Designers must find the right balance based on application needs.

Smooth Transitions: Avoid sharp corners, which concentrate stress and accelerate mold wear. Instead, incorporate radii to enhance durability and ease mold release.

Fiber Orientation: Glass fibers align with the flow direction during molding, affecting strength and shrinkage. Designers must account for this anisotropy to optimize part performance.

Shrinkage Management: Glass-filled nylon exhibits higher shrinkage (0.5–1.5%) than unfilled nylon.

Managing Weld Lines: Proper gate placement and flow paths reduce weak weld lines where glass fibers may not align well.

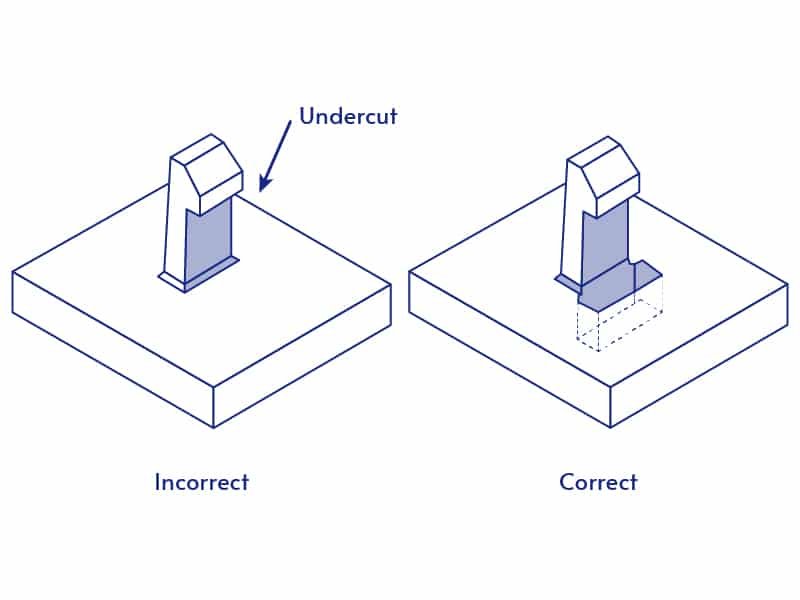

Draft Angles and Gating: Use draft angles of 1–2° for easy part ejection and optimize gate locations to control fiber alignment, reducing defects like weld lines.

Injection Molding Temperature: Glass filled nylon injection molding temperature is generally higher than unfilled nylon, often ranging between 260°C to 290°C, requiring precise temperature control to ensure good flow and fiber dispersion.

Is Glass-Filled Nylon Suitable for Your Project?

Glass-filled nylon is suitable for projects demanding strength, precision, and heat resistance. It excels in applications like automotive gears or industrial pump housings, where glass-filled nylon injection molding delivers robust components that withstand high stress and temperatures up to 200°C, leveraging optimized glass-filled nylon injection molding temperature profiles. Its dimensional stability makes it ideal for precise parts like electronic connectors, and its cost-effectiveness suits high-volume production of consumer goods via glass-filled plastic injection moulding. However, its brittleness renders it unsuitable for flexible or impact-prone parts, such as hinges or shock-absorbing components, where other materials may perform better.

For prototyping or low-volume needs, glass-filled nylon shines in CNC machining, offering precision for complex designs like prototype brackets, though it produces material waste. In 3D printing, it supports rapid design iterations with compatible resins, ideal for early-stage mockups like enclosures, despite lower strength compared to molded parts.

Conclusion

Glass-filled nylon injection molding is a versatile solution for creating durable, precise components across automotive, industrial, consumer goods, and electronics applications. Its strength, heat resistance, and dimensional stability make it an excellent alternative to metals, though its brittleness and mold wear require careful design. Whether for high-volume production or prototyping via CNC machining or 3D printing, glass-filled plastic injection moulding delivers reliable performance when applied thoughtfully. Ready to see if it’s right for your project? Contact Jiangzhi’s expert team to explore how glass reinforced nylon injection moulding service can bring your design to life.