HDPE molding can produce durable, lightweight, and cost-effective parts. Those HDPE parts meet the demands of industries like packaging, automotive, and consumer goods. This guide explores the HDPE molding process, design tips,its advantages, applications, and challenges, offering insights for clients seeking sustainable, high-performance solutions through injection hdpe.

What is HDPE?

High-density polyethylene (HDPE) is a semi-translucent, non-polar thermoplastic characterized by high crystallinity. Typically appearing as natural-colored cylindrical or lenticular granules, it offers excellent rigidity, tensile strength, and impact resistance. HDPE also demonstrates outstanding resistance to chemicals, low water absorption, and superior dimensional stability under thermal or mechanical stress. Its surface is waxy and smooth, and it retains strength and toughness across a wide temperature range.

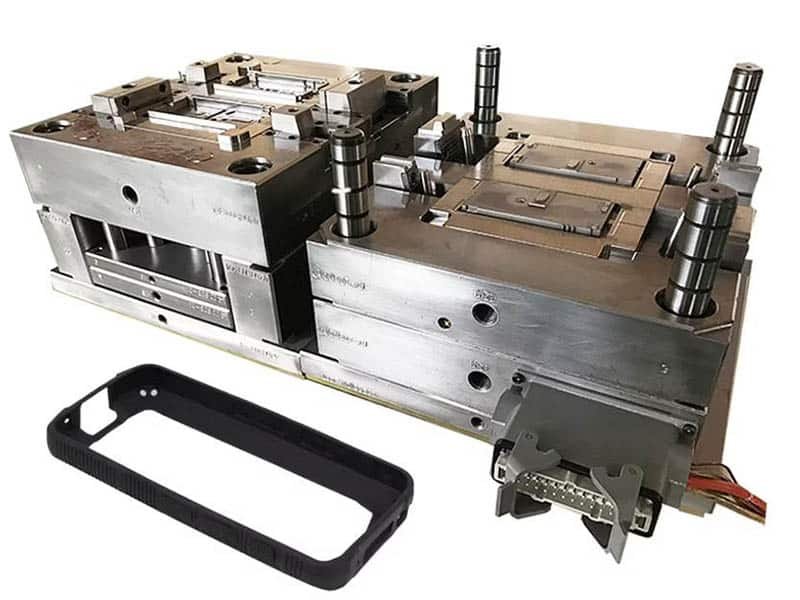

What is HDPE Molding?

HDPE molding refers to the process of shaping high-density polyethylene (HDPE) into functional plastic parts using methods like injection molding, blow molding, or extrusion. Known for its excellent strength, chemical resistance, and low moisture absorption.

HDPE: An Ideal Choice for Injection Molding Parts

High-density polyethylene (HDPE) is a versatile thermoplastic that has gained popularity in injection molding thanks to its impressive balance of strength, flexibility, and chemical resistance. Known for its toughness and low moisture absorption, HDPE performs well under demanding conditions, making it suitable for a wide range of plastic injection molding parts.

One of HDPE’s most notable advantages is its recyclability, supporting environmentally conscious manufacturing processes. With excellent processability and reliable performance, HDPE injection molding service has become a preferred production and processing method such as construction, automotive, packaging, and household products. Its combination of durability and sustainability makes it a smart choice for both functional and eco-friendly designs.

A List of HDPE Injection Molding Characteristics

| Property | Typical Value |

|---|---|

| Density | 0.954 g/cm³ |

| Tensile Strength | 26.2 MPa |

| Elongation at Break | 583 % |

| Melt Temperature | 246–280 °C |

| Mold Temperature | 45–65 °C |

Contact our engineers for the best plan for your custom parts.

HDPE Molding Design Tips

In HDPE injection molding, some specific design and process requirements must be considered to ensure product quality and minimize defects.

- Higher Injection Temperature Range: HDPE has a high melting temperature, typically between 200-240°C. Precise temperature control is essential. Excessive temperatures can cause burning, flash, and uneven shrinkage, while insufficient temperatures may lead to flow marks, weld lines, and short shots.

- Part Tolerances: HDPE has a relatively high shrinkage rate, which can make achieving tight tolerances challenging. As a result, designers should avoid overly tight dimensional requirements. Standard tolerances for HDPE molded parts are generally around ±0.25 mm to ±0.50 mm depending on part size and geometry. Where tighter tolerances are needed, post-machining or careful process control may be necessary.

- Uniform Wall Thickness Design: HDPE has a high shrinkage rate (approximately 1.5%-2.5%) and is easy to warping. Therefore, designs must ensure uniform wall thickness, avoiding significant variations (transitions should be controlled within 10%-15%) to reduce warping and shrinkage issues. The minimum wall thickness typically ranges from 0.76 to 3.18 mm.

- Appropriate Injection Pressure: HDPE has high melt viscosity, requiring a balance of pressure and speed to ensure complete filling without damaging the material. Pressure is usually maintained between 800 and 1500 psi.

- Reasonable Fillet and Draft Angle Design: HDPE’s high melt viscosity and poor flowability can lead to stress concentration. Injection-molded parts should include appropriate fillets (inner and outer radii at least 25% of wall thickness, ideally 75%) to reduce stress concentration and improve melt flow. Draft angles are generally set at 0.5° to 1° to facilitate demolding.

- Mold Design Requirements: HDPE is sensitive to cooling rates, so molds must have an effective cooling system to ensure uniform cooling. Mold temperatures should be controlled between 30-50°C, with properly placed gates (typically at the thickest sections) and venting channels to prevent gas entrapment and poor filling.

- Multi-Gate Design: Due to HDPE’s poor flowability, uneven filling and internal defects are common. Multi-gate designs are necessary to ensure uniform mold filling, reduce internal stresses and localized overcooling, and prevent warping and sink marks.

Benefits of HDPE Molding

The advantages of HDPE molding drive its adoption across industries, offering unmatched performance and efficiency in high density polyethylene molding.

Cost Efficiency

HDPE is a common used injection molding plastic material. It is cost efficiency tan specialty plastic ans polymer blends and fast cycle times (20–60 seconds) reducing production costs. This efficiency makes injection hdpe ideal for high-volume runs (10,000+ units), minimizing expenses while maintaining quality, a key benefit of HDPE molding.

Durability and Strength

HDPE’s high tensile strength (20–40 MPa) and impact resistance ensure parts endure harsh conditions, from industrial tanks to automotive components. This durability, a hallmark of high density polyethylene injection molding, supports long-lasting applications.

Chemical Resistance

Resistant to acids, bases, and solvents, HDPE excels in containers and pipes, a critical advantage of hdpe injection. This property ensures reliability in chemical-heavy environments, enhancing HDPE molding’s appeal.

Lightweight

With a low density (0.94–0.97 g/cm³), HDPE molding produces lightweight parts, reducing shipping costs and material use. This benefit is vital for automotive and packaging applications using injection hdpe.

Recyclability

HDPE’s full recyclability supports sustainable manufacturing, aligning with circular economy goals. This eco-friendly aspect of high density polyethylene molding appeals to environmentally conscious industries.

Versatility in Design

HDPE injection molding supports complex shapes, thin walls, and features like hinges or threads, offering design flexibility. Its compatibility with injection, blow, and extrusion molding enhances HDPE molding’s versatility.

Weather and UV Resistance

With UV additives, HDPE resists degradation and weathering, ideal for outdoor parts like irrigation pipes. This resilience strengthens hdpe injection for agricultural and recreational applications.

FDA Compliance

Food-grade HDPE meets FDA standards, enabling safe use in food packaging and medical devices. This compliance underscores the HDPE molding benefits for health-related industries.

Challenges and Limitations

Despite the benefits, HDPE molding has limitations in high density polyethylene injection molding.

Limited Heat Resistance

HDPE softens above 120°C, restricting hdpe injection in high-temperature applications like engine components, necessitating alternative materials.

Susceptibility to Stress Cracking

Prolonged chemical or stress exposure can cause environmental stress cracking, a challenge for HDPE molding in harsh conditions, requiring material testing.

Post-Processing Needs

Some injection hdpe parts need deflashing or surface treatment for aesthetics, increasing costs and offsetting HDPE molding’s cost efficiency.

High Thermal Expansion

HDPE’s high thermal expansion coefficient (100–200 µm/m·K) causes dimensional changes with temperature fluctuations, requiring precise mold tolerances in HDPE injection molding.

Flammable

HDPE is flammable, necessitating flame-retardant additives for fire-prone applications, adding complexity and cost to HDPE injection processes.

Difficult to Bond

HDPE’s low surface energy hinders adhesive bonding and overmolding, limiting multi-material applications in HDPE molding and requiring specialized treatments.

Applications of HDPE Molding

HDPE molding serves diverse industries, leveraging its durability and versatility through high density polyethylene injection molding.

- Packaging Industry: HDPE injection molding produces chemically resistant, FDA-compliant bottles, caps, and containers. Examples: milk jugs, detergent bottles, bottle caps.

- Automotive Components: Injection HDPE creates lightweight, durable parts like fuel tanks, air ducts, and interior panels, enhancing vehicle efficiency.

- Consumer Goods: HDPE molding manufactures robust household items, including buckets, toys, and storage bins, capitalizing on design flexibility.

- Industrial Applications: High density polyethylene molding delivers corrosion-resistant pipes, fittings, and chemical tanks for heavy-duty use.

- Medical and Pharmaceutical: Hdpe injection produces sterile components like syringe barrels and medical containers, meeting FDA standards.

- Agricultural and Outdoor: HDPE molding crafts weather-resistant irrigation pipes, crates, and playground equipment, ideal for outdoor durability.

Start HDPE Molding with Jiangzhi

HDPE molding delivers durable, lightweight, and recyclable parts, excelling in industries like packaging, automotive, and medical through HDPE injection molding. Jiangzhi has experience in hdpe injection services, offers tailored solutions to maximize injection hdpe performance. Contact Jiangzhi to collaborate on your next project.