The injection molding cooling system is crucial in mold design and has a great impact on the molding cycle and product quality of the product. Therefore, the uniform and reasonable design of the cooling water channel has a far-reaching impact on improving product quality and accelerating the molding cycle of the product. An efficient mold cooling system is key to faster production and defect-free plastic parts. This chapter introduces the cooling method of the injection mould, the layout of the cooling water channel injection molding, and the general rules of the mold cooling system design.

Components of an Injection Mould Cooling System

Injection mold cooling systems are intricate networks designed to ensure the consistency, efficiency, and quality of the final molded product. Here are the main components that up these systems:

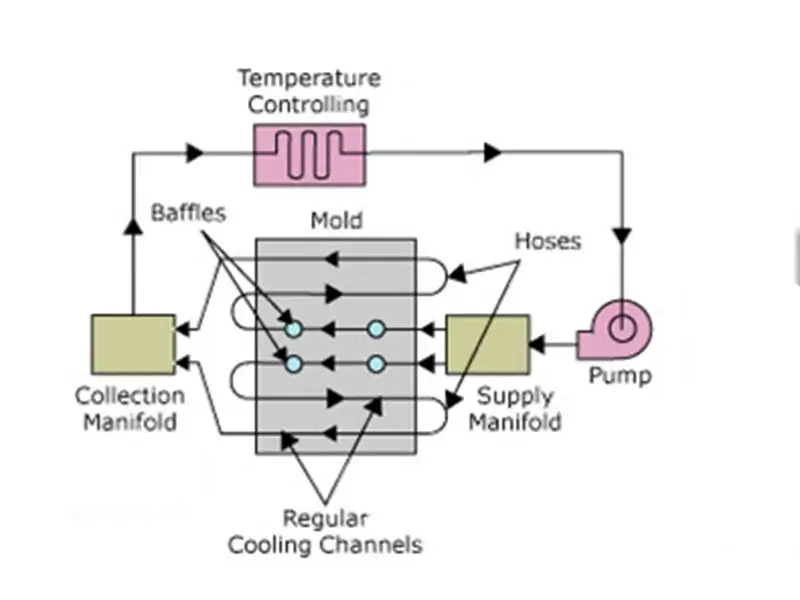

Cooling Channels: These are essential elements in the plastic mold cooling system, guiding the cooling medium throughout the mold. These channels ensure uniform cooling, preventing product defects and ensuring a faster cycle time.

Coolant: The most commonly used cooling mediums are water and air. Water is preferred for its excellent heat conductivity, which ensures prompt cooling and faster injection moulding cycles. Air cooling is simpler and requires less maintenance.

Heat Exchangers and Injection Molding Chillers: These help maintain consistent mold temperatures, which is essential for plastic injection mold cooling system performance and preventing overheating.

Pumps and Flow Regulators: These control the pressure and flow rate of the cooling medium, ensuring it reaches every part of the mold uniformly. These components are essential for maintaining efficient mold cooling and preventing hotspots within the mold.

Baffles and Bubblers: Baffles and bubblers are used to enhance cooling in difficult-to-reach areas of the mold. Baffles are cooling channels drilled perpendicular to the main cooling line, equipped with a blade that divides the cooling flow into two semi-circular paths. Bubblers function similarly, adding cooling capacity in challenging regions.

Thermal Pins: Thermal pins are used to increase the efficiency of heat transfer within the mold. They are inserted into the mold to conduct heat away from specific areas, helping to maintain temperatures and reduce cooling times.

Different Types of Injection Mould Cooling Systems

1. Conformal Cooling

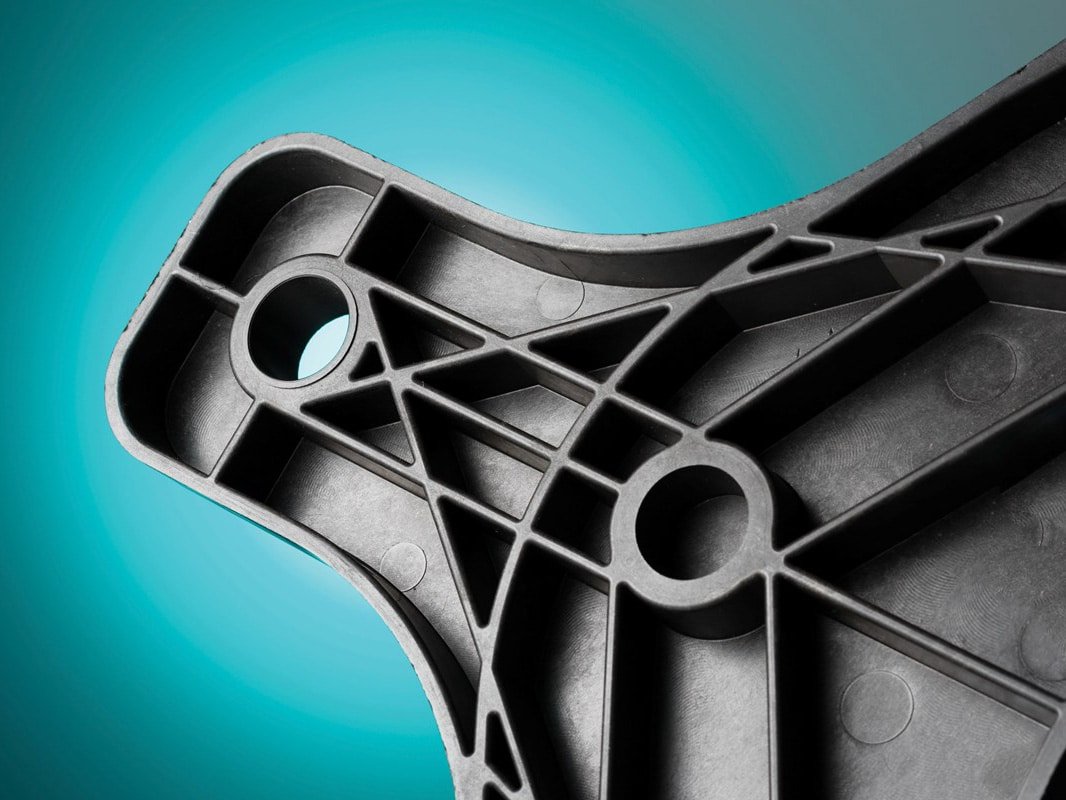

Conformal cooling channels follow the contour of the mould cavity, enabling even and efficient heat removal. These channels are often created using 3D printed cooling channels for injection molding. Conformal cooling is particularly effective for complex or large molds, providing uniform cooling and reducing cycle times.

2. Baffle and Bubbler Systems

Baffles and bubblers are used when direct cooling channels are impractical. Baffles split the coolant flow into two paths, increasing the surface area for heat exchange. Bubblers, on the other hand, are small tubes that direct coolant into deep or narrow mold areas.Used when direct cooling channels are impractical. These are key in complex mold cooling solutions, especially for deep cores or hard-to-reach spots.

3. Straight-Line Cooling Channels

These are the most basic type of cooling system, consisting of straight channels drilled into the mold. They are simple to manufacture and suitable for less complex molds. However, they may lead to uneven cooling in intricate designs.

4. Spiral Cooling Systems

Spiral cooling involves channels arranged in a spiral pattern, often used for cylindrical molds like bottle caps or containers. This configuration ensures uniform cooling around the mould.

5. Hot Oil or Hot Water Cooling

For molds processing materials that require slower cooling or precise temperature control, hot oil or hot water systems are used. These systems are particularly beneficial for heat-sensitive plastics or rubber materials.

6. Hybrid Cooling Systems

Combining different cooling methods can address specific mold design challenges. For example, a mold might use conformal cooling in critical areas and straight-line channels elsewhere, balancing efficiency and cost.

Selecting the appropriate cooling system depends on factors such as material type, mold complexity, production volume, and required cycle time. Combining multiple cooling methods in a custom injection mold cooling system design helps balance cost and performance.

Optimize Your Production with an Advanced Injection Mold Cooling System

Injection Mold Cooling System Design Principles

To improve productivity and ensure product quality, the basic principle of designing an efficient injection mold cooling system is to ensure uniform cooling of plastic injection molded parts.

Maximize the Number and Size of Cooling Channels

The temperature of the cavity surface is closely related to the size and density of the cooling channels. Larger diameter cooling channels and smaller channel spacing result in a more uniform cavity surface temperature.

Appropriate Distance from Cooling Channels to Cavity Surface

The distance between the channel wall and the cavity surface should generally be greater than 10mm, with 12-15mm being commonly used. If too close, the cavity surface temperature becomes uneven; If too far, thermal resistance increases and cooling efficiency decreases.

For parts with uniform wall thickness, maintain the same distance between the cooling channels and the cavity surface. For parts with uneven wall thickness, place the cooling channels closer to the cavity surface near thicker walls.

Parallel Water and Material Flow to Enhance Cooling at the Gate

During molding, high-temperature plastic melt enters the cavity through the gate, causing higher temperatures near the gate and lower temperatures at the material flow’s end.

Position the cooling water inlet near the gate, ensuring that the cooling water flows in the same direction as the material in the cavity, leading to more uniform cooling.

Maintain a Small Temperature Difference Between Inlet and Outlet Water

A large temperature difference between the inlet and outlet water causes uneven mold temperature distribution. To achieve a consistent cooling speed across the product, arrange cooling channels to minimize the temperature difference between inlet and outlet water.

Reasonable Arrangement of Cooling Channels

Cooling channel layout should align with mold cavity design to provide adequate coverage and uniform heat removal.

Ease of Processing and Assembly for Cooling Channels

Design the cooling water channel in injection molding to allow for simple drilling or machining, minimizing production costs and delays.

Common Issues Caused by Improper Injection Mold Cooling System

An improperly designed or maintained injection mold cooling system can lead to several issues that affect the quality of molded parts and the efficiency of the production process. This section outlines common problems and provides solutions to address them effectively.

Uneven Cooling and Warping

Cooling channels placed too far from the mold cavity, with uneven spacing, variations in coolant flow rate, or significant differences in the temperature between different parts of the mold will cause uneven cooling and warping.

Solutions:

Optimize channel placement and ensure cooling channels are placed as close to the cavity as possible, with consistent spacing, to achieve uniform cooling.

Use temperature control units (TCUs) to regulate and maintain consistent flow rates throughout the mold.

Ensure the coolant temperature is evenly distributed across the mold by minimizing the temperature difference between inlet and outlet water.

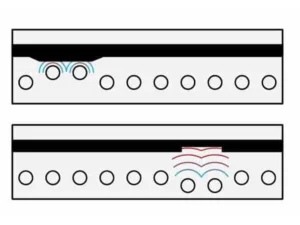

Cooling Channel Blockage

Lack of regular cleaning and maintenance can cause particles, scale, and debris in the coolant to block the channels.

Solutions:

Implement filtration systems to remove contaminants from the coolant. Schedule regular cleaning and inspection of cooling channels to prevent blockages. Use appropriate cleaning agents to remove scale and corrosion.

Conclusion

A well-designed scientific molding cooling system is essential for high-quality injection molded parts and efficient production. By focusing on uniform cooling, using the right tools, and regularly maintaining the system, manufacturers can avoid defects, reduce costs, and speed up cycle times. For any custom mold cooling system design needs, reach out to professionals who understand the details that drive performance.

FAQ About Injection Mold Cooling

Conformal cooling systems are ideal due to their ability to follow cavity contours and ensure uniform heat removal.

Typically 12–15mm is optimal. Too close causes surface irregularities, while too far reduces cooling efficiency.