Injection molding parameters are key to precision and efficiency in the injection molding process, transforming molten plastic into flawless components with high accuracy. Understanding and optimizing these parameters is essential for achieving exceptional manufacturing outcomes. This knowledge is particularly valuable for projects involving high-volume injection molding, where consistency, quality, and efficiency are critical. By dissecting each parameter’s function and its impact on part quality, you can reduce defects and enhance overall production efficiency.

What Are Injection Molding Parameters?

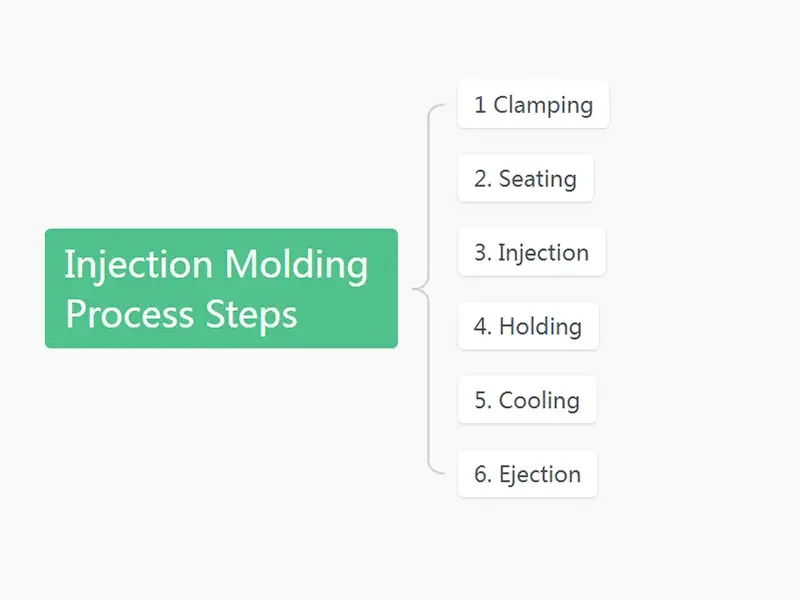

Injection molding parameters refer to the critical process variables that control and regulate the flow, filling, cooling, and solidification of molten plastic within a mold during the injection molding process. These include temperature, pressure, speed, and time-based variables, each influencing how molten plastic behaves within the mold. From the moment resin pellets are heated to the final ejection of the part, these parameters dictate the process’s success.

Even minor deviations can lead to defects, wasted materials, or extended cycle times. By calibrating these settings, manufacturers ensure parts meet stringent quality standards, maintaining uniformity across high-volume runs.

Key Injection Molding Parameters

Injection molding parameters govern every stage from material melting to part ejection. Now, let’s start to learn the key injection molding parameters during the injeciton molding process. injectionure Control

Temperatures during injection molding process include melt temperature, mold temperature, and barrel temperature. Those temperatures dictate how smoothly the plastic flows into the mold. Melt temperature ensures the resin reaches a viscous state suitable for injection. Mold temperature influences cooling rates, while barrel temperature maintains material consistency during heating.

Proper temperature settings enhance part quality and reduce cycle times. Optimal melt temperatures promote uniform flow, preventing issues like burn marks or poor surface finish. Mold temperatures, when correctly set, ensure even cooling, reducing residual stresses that lead to warpage. Efficient temperature management also shortens cooling times, boosting overall production efficiency.

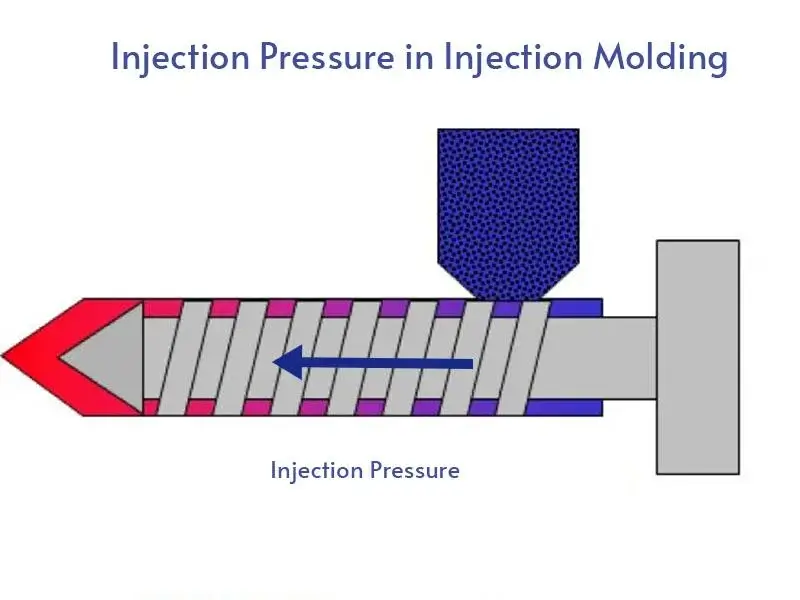

Injection Pressure

Injection pressure impacts on material flow. Injection pressure drives molten plastic into the mold cavity, a critical step in shaping the part. This injection molding parameter determines how completely and uniformly the mold fills. Higher pressures ensure intricate details are captured, especially in complex geometries. However, the pressure must align with the material and mold design to avoid defects.

Excessive pressure can cause flash, where excess material seeps out of the mold. Conversely, insufficient pressure may result in short shots, leaving parts incomplete.

Injection Speed

The injection speed influences the filling speed governs how quickly molten plastic enters the mold. This parameter affects fill uniformity and part consistency. A well-calibrated speed ensures the material reaches all areas of the mold before cooling begins, critical for complex or thin-walled parts.

Different plastics demand tailored injection speeds. Understanding material properties before set injection speed will rectify the injection molding defects. In injection molding, PET injection molding process parameters often require moderate speeds to prevent degradation, while high-viscosity materials like polycarbonate may need faster injection to ensure complete filling.

Holding Pressure and Time

The holding phase applies sustained pressure after initial injection to pack additional material into the mold. This step, governed by injection molding process parameters, prevents defects like sink marks or voids caused by material shrinkage during cooling.

Fine-tuning holding pressure and time will improve the surface finish and structural integrity. Too little pressure can lead to shrinkage-related defects, while excessive pressure may cause stress marks or mold damage.

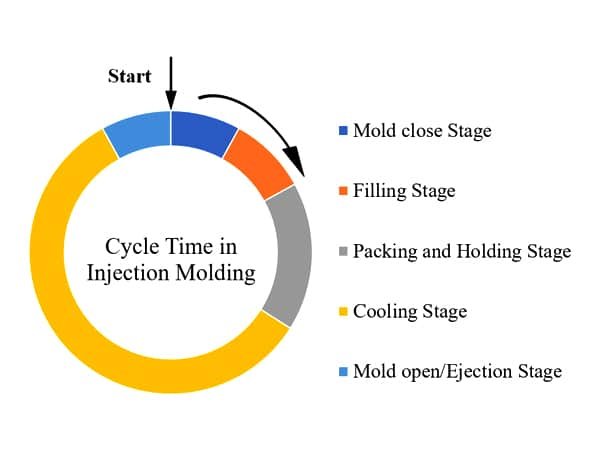

Cooling Time

Cooling time determines how long the part remains in the mold to solidify. This parameter injection molding is important for achieving dimensional stability and mechanical strength. Proper cooling prevents premature ejection, which can deform parts. It also influences the overall cycle time, impacting production efficiency.

Cooling time varies based on material type, part thickness, and mold design. Thicker parts require longer cooling to ensure uniform solidification. Materials with high thermal conductivity cool faster than others. Mold design also plays a significant role in determining cooling duration.

Clamping Force

Clamping force keeps the mold halves securely closed during injection. This injection moulding parameter counteracts the pressure exerted by the molten plastic, preventing mold separation. Adequate clamping ensures part precision and prevents defects like flash or misaligned components.

Determining the right clamping force involves calculating the projected area of the part and the pressure exerted during injection. Insufficient force risks mold opening, while excessive force can damage the mold or machine.

Screw Speed and Back Pressure

Screw speed and back pressure control how resin is melted and mixed in the barrel. These injection molding critical parameters ensure uniform material consistency. Proper settings promote even melting, reducing air entrapment or unmelted pellets that could compromise the final product.

Excessive screw speed or back pressure can overheat the material, leading to degradation. Careful adjustment prevents issues like discoloration or weakened mechanical properties, preserving material integrity throughout the process.

Cycle Time

Cycle time encapsulates the entire molding process, from injection to ejection. It reflects the interplay of all injection molding parameters, including injection, holding, cooling, and mold opening times. Optimizing cooling time, streamlining injection speed, and fine-tuning pressure settings will reduce cycle time, enhance production efficiency, and enhance.

Common Defects and Parameter Adjustments

Some injection molding defects are caused by improper injection molding parameters. Each defect signals a need for parameter adjustment.

Sink Marks

Sink marks manifest as depressions on the part surface, often due to uneven cooling or insufficient material packing. Low holding pressure or inadequate cooling time are common culprits. To prevent sink marks, increase holding pressure to ensure sufficient material is packed into the mold during cooling. Extending cooling time allows for uniform solidification, especially in thicker areas. Adjusting mold temperature to promote even cooling can also mitigate this defect.

Warpage

Warpage results from residual stresses that distort the part during cooling. Uneven mold temperatures or rapid cooling rates often cause this issue, as differential shrinkage creates internal stresses. To address warpage, balance mold temperatures to ensure uniform cooling across the part. Reducing cooling rates by extending cooling time or lowering mold temperature for high-shrinkage materials can help. Consistent temperature control is key to maintaining dimensional stability.

Flash

Flash occurs when excess material seeps out of the mold seams, creating thin, unwanted protrusions. This is typically caused by excessive injection pressure or insufficient clamping force. To prevent flash, reduce injection pressure to a level that fills the mold without forcing it open. Increasing clamping force ensures the mold remains sealed.

Short Shots

Short shots result in incomplete parts due to insufficient material filling the mold cavity. Low injection pressure, inadequate injection speed, or improper melt temperature often cause this issue. To correct short shots, increase injection pressure or speed to ensure complete filling. Raising the melt temperature can reduce viscosity, improving flow, especially for high-viscosity materials.

Common Material Injection Molding Parameters

Different plastics require customized injection molding process parameters to achieve optimal results. Material properties like viscosity, melting point, and shrinkage rate dictate specific settings for temperature, pressure, and cooling. The following table provides a detailed guide to parameter settings for common materials.

| Material | Melt Temperature (°C) | Mold Temperature (°C) | Injection Pressure (MPa) | Cooling Time (s) |

|---|---|---|---|---|

| Nylon (PA) | 240-290 | 60-100 | 80-140 | 20-40 |

| ABS | 230-270 | 40-80 | 80-120 | 20-40 |

| Polycarbonate (PC) | 280-320 | 80-120 | 100-150 | 30-50 |

| Polyoxymethylene (POM) | 180-220 | 60-100 | 80-130 | 20-35 |

| Polystyrene (PS) | 180-260 | 20-60 | 70-110 | 15-30 |

| Polypropylene (PP) | 200-250 | 20-60 | 70-110 | 15-30 |

| Acrylic (PMMA) | 220-260 | 50-80 | 80-130 | 20-40 |

| Polyethylene (PE) | 180-240 | 20-60 | 60-100 | 15-30 |

| HDPE | 190-250 | 20-60 | 60-100 | 15-30 |

| UHMWPE | 200-260 | 30-70 | 70-110 | 20-35 |

Conclusion

Mastering injection molding parameters requires continuous learning and adaptation. Experienced manufacturers can set the appropriate parameters based on material properties, mold designs, and production goals. As a leading Chinese injection molding supplier, Jiangzhi combines advanced equipment, skilled engineers, and strict quality control to deliver precision and efficiency for global customers. Our injection molding experts are meticulous in optimizing parameters to produce high-quality plastic parts that meet international standards. The injection molding experters is hyper-vigilant in setting the correct parameters for producing the high quality products. Welcome to contact and make your design come true products.